Component mounting apparatus

A technology for mounting machines and components, applied in the direction of electrical components, electrical components, etc., can solve problems such as product quality decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

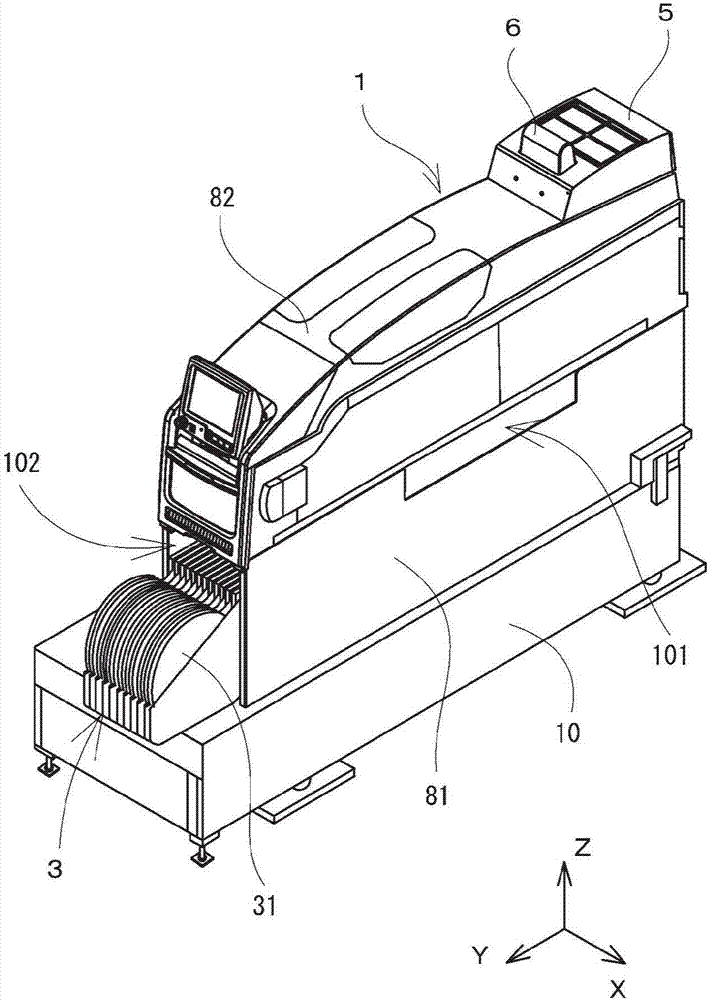

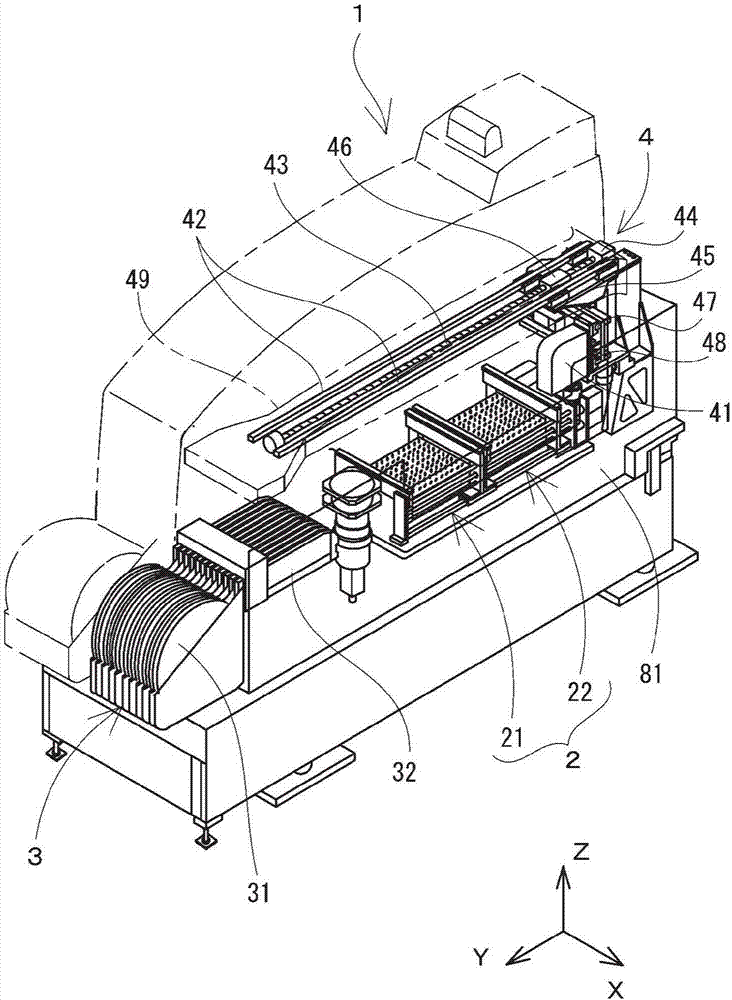

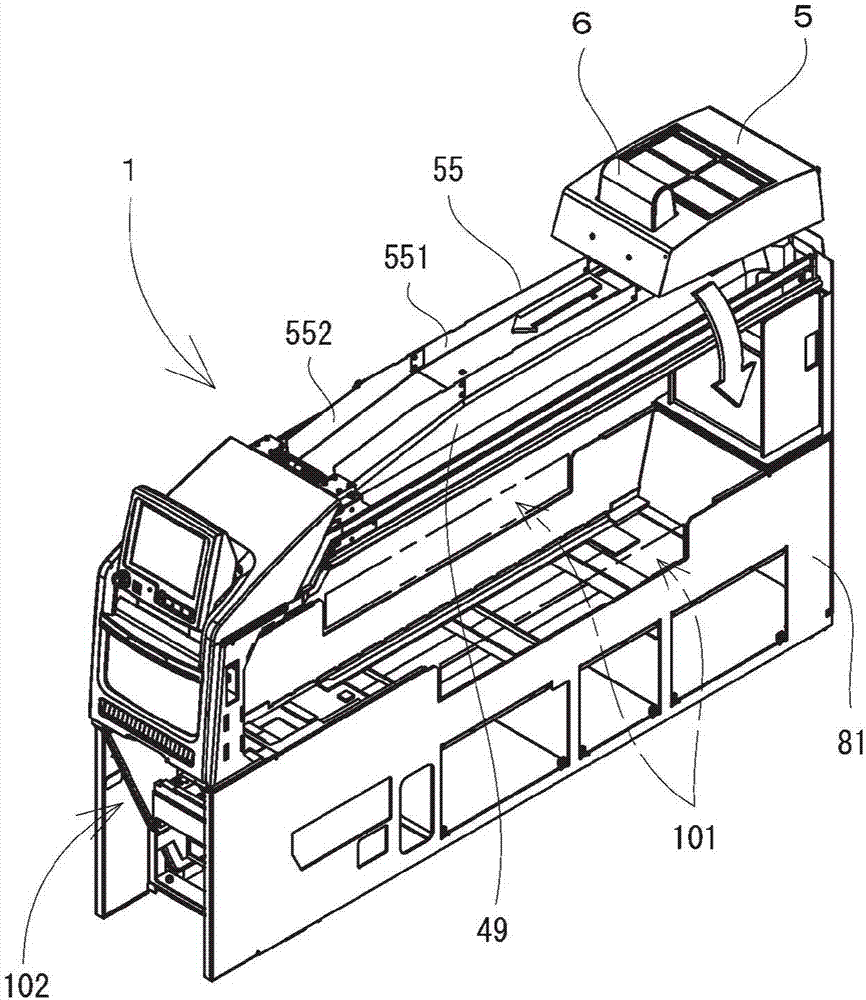

[0020] Next, an embodiment of the component mounting machine of the present invention will be described below with reference to the drawings. In the present embodiment, an electronic component mounting machine for mounting electronic components on a circuit board will be described as an example. figure 1 It is an external appearance perspective view which shows this electronic component mounting machine. The electronic component mounting machine 1 shown here is a structure in which a plurality of mounting machines of the same type are arranged in the width direction to constitute a component mounting line for mounting predetermined electronic components on a circuit board. That is, in the component mounting line, circuit boards are sequentially conveyed into each electronic component mounting machine 1, and predetermined electronic components are mounted in each mounting machine.

[0021] exist figure 1 In the figure, the state where one electronic component mounting machine...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap