Thermal granular thermal fuse

A thermal fuse, particle type technology, applied in the field of heat sensitive particle type thermal fuse, to achieve the effect of high operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

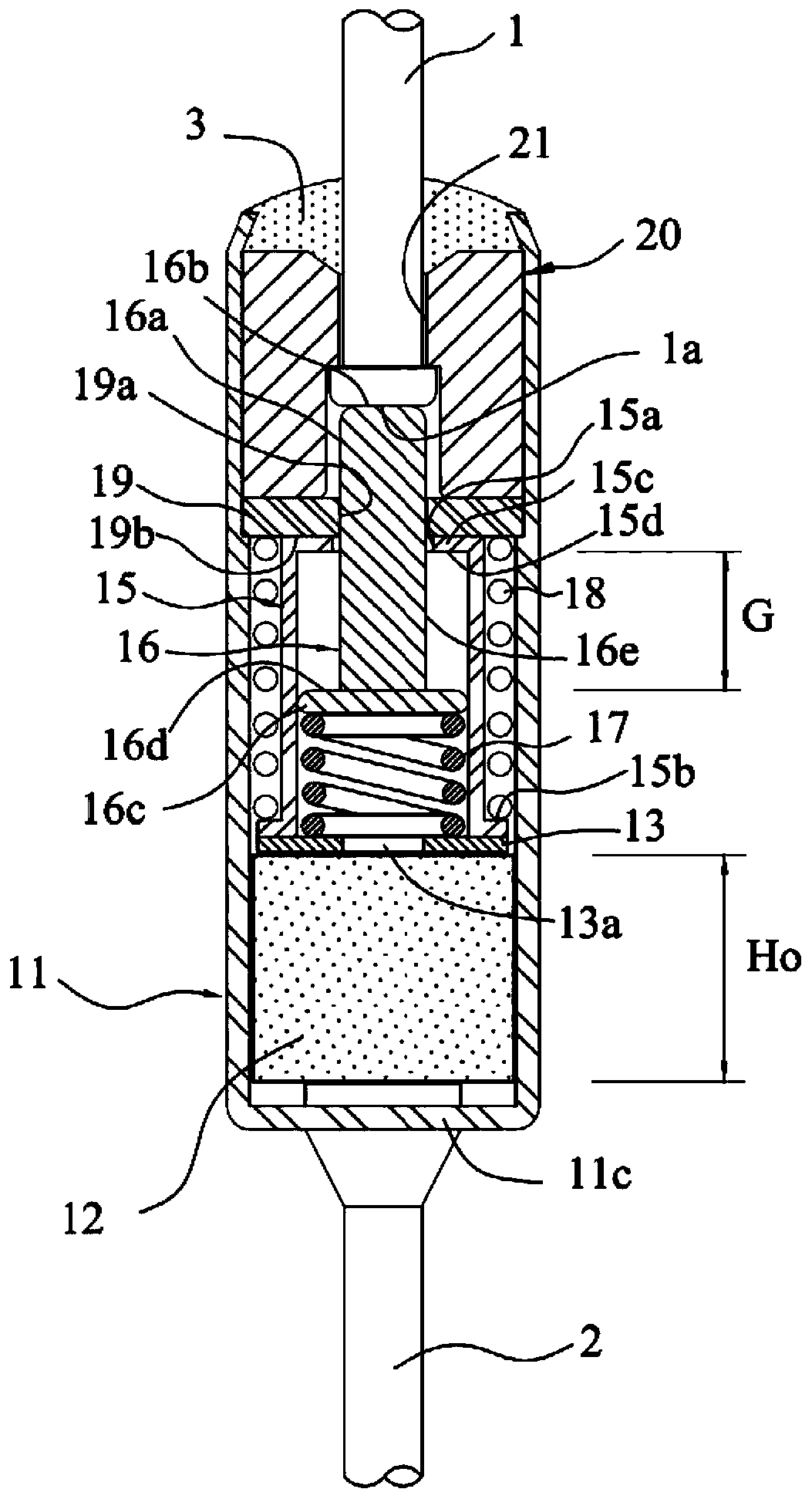

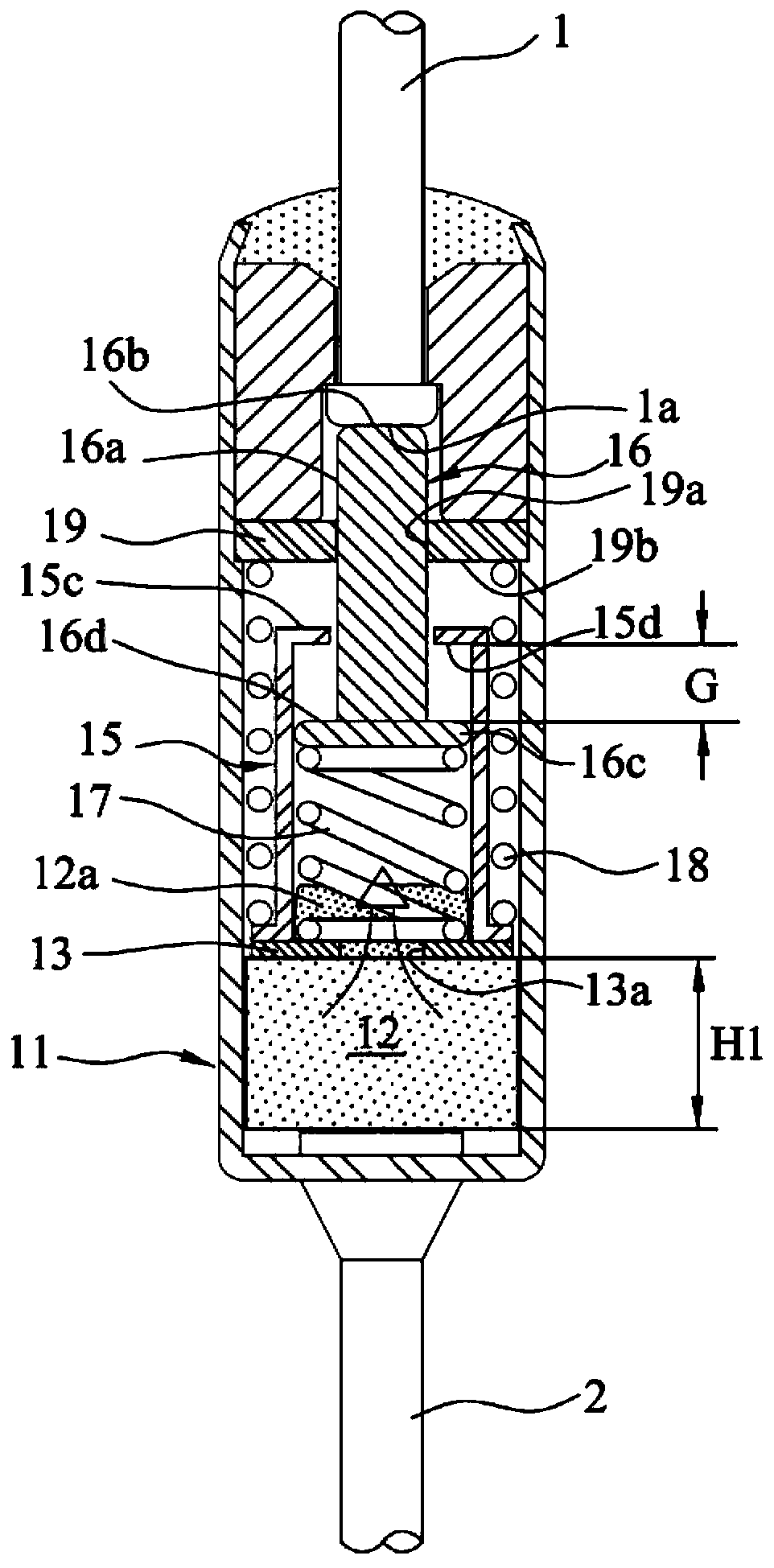

[0044] Hereinafter, preferred embodiments of the thermosensitive pellet type thermal fuse according to the present invention will be described in detail with reference to the accompanying drawings.

[0045] Such as figure 1 with figure 2 As shown, one side of the heat-sensitive pellet type thermal fuse according to the present invention is opened, and the other side includes a metal case 11 having a bottom 11c. The housing 11 is composed of an upper area with a relatively larger inner diameter and a lower area with a relatively smaller inner diameter, and a stepped portion is formed at a boundary between the upper area and the lower area.

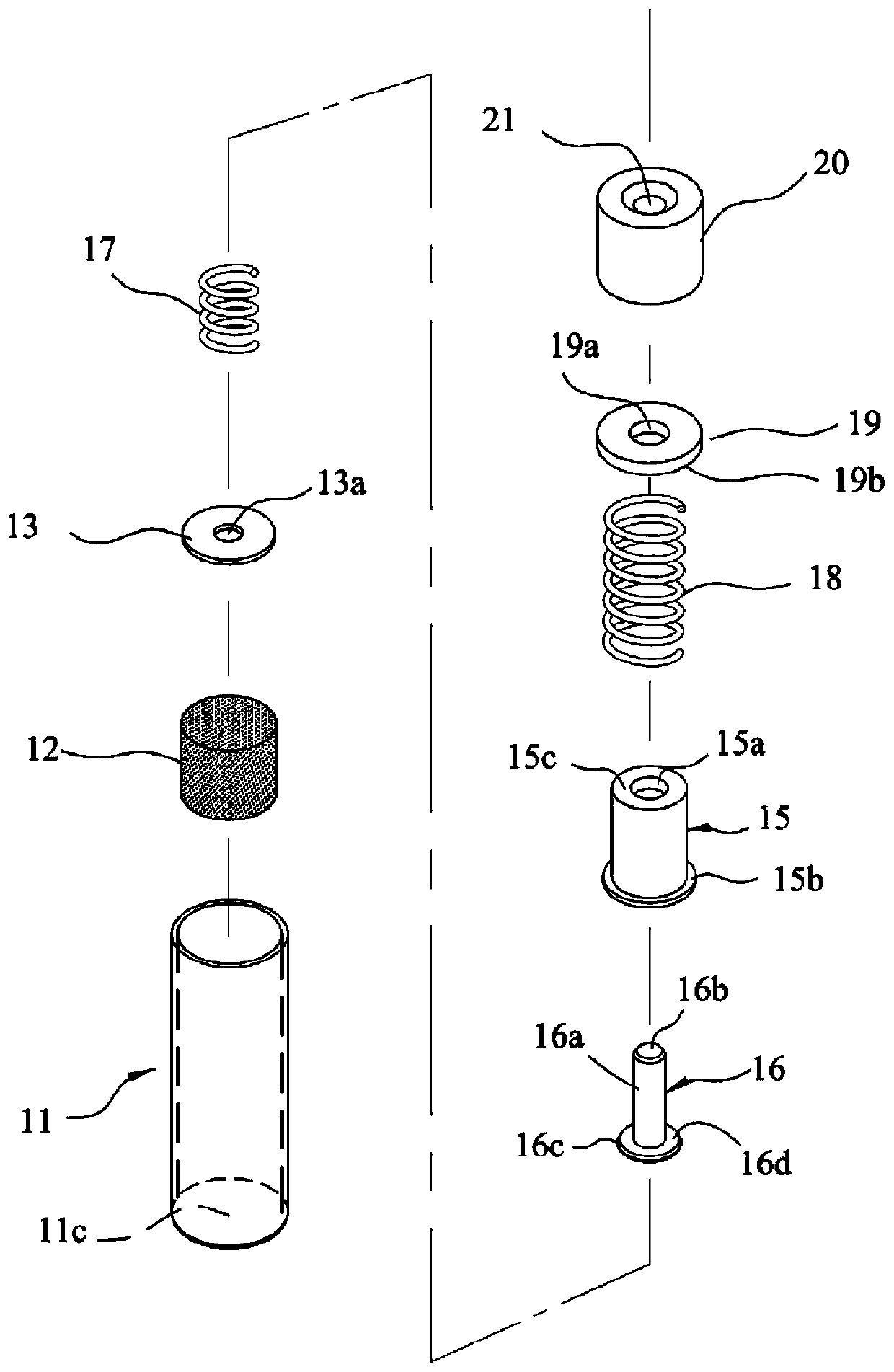

[0046] In the lower area of the housing 11, a heat-sensitive particle 12, a backing plate 13, a first spring 17, a movable terminal 16, an operating part 15, and a second spring 18 are sequentially inserted from the bottom 11c of the housing 11. , and in the upper region of the housing 11, a fixed terminal board 19 and an insulating sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com