Automatic magnetic buckle and automatic buckling method

A buckle and automatic technology, applied in the direction of mechanical equipment, fixing devices, etc., can solve the problems of unstable fixing, inaccurate connection position, poor practicability, etc., and achieve the effect of saving operation steps and time and improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

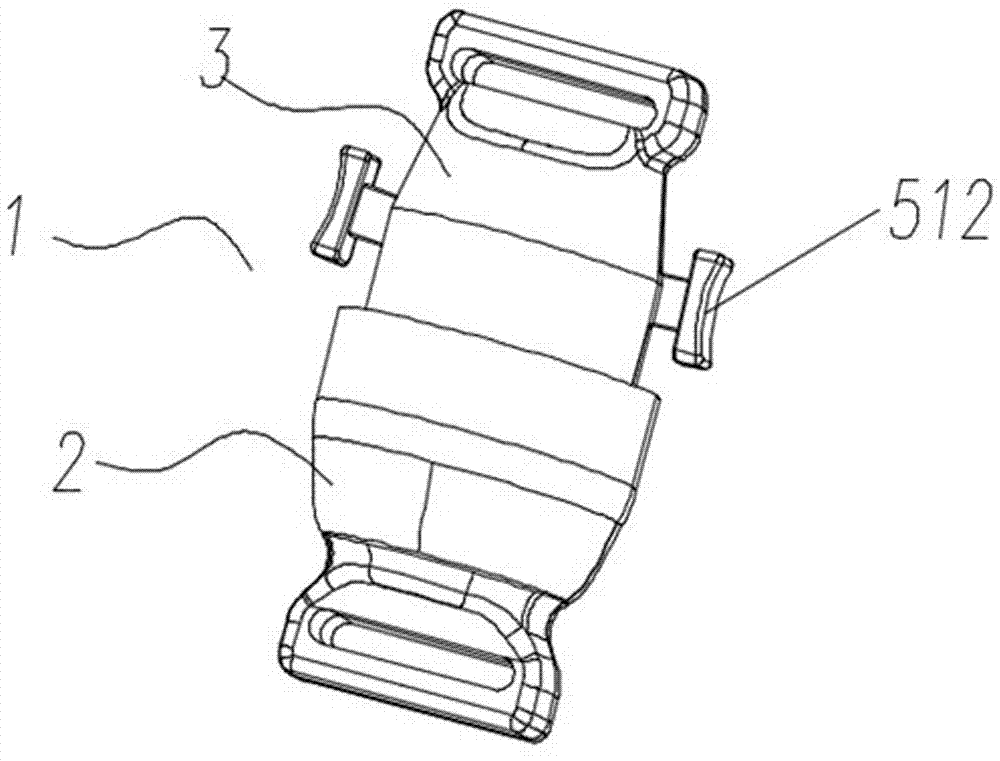

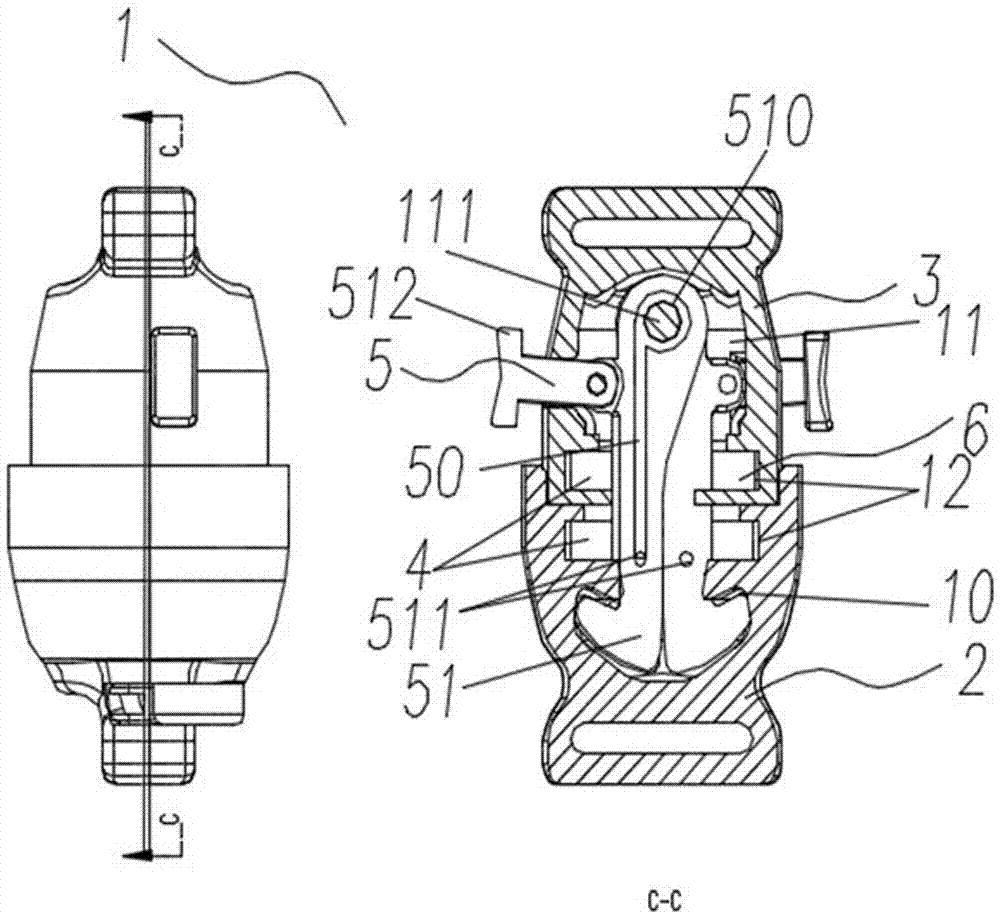

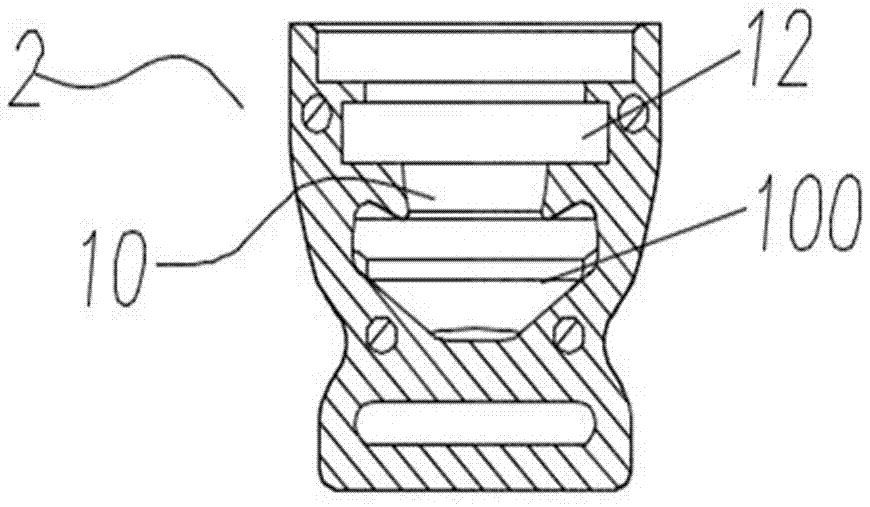

[0040] Embodiment 1, see attached Figure 1~6 , an automatic magnetic buckle including a buckle body 1, the buckle body 1 is provided with a buckle seat 2, a buckle head 3, a magnetic attraction component 4 and a buckle component 5; the buckle seat 2 is provided with an annular fastening groove 6. The buckle component 5 is mated and fastened with the ring-shaped fastening groove 6 , the magnetic attraction component 4 is respectively set in the buckle seat 2 and the buckle head 3 , and the buckle component 5 is set in the buckle head 3 .

[0041] The buckle body 1 is provided with a cavity one 10 and a cavity two 11, the cavity one 10 is set in the buckle seat 2, the cavity two 11 is set in the buckle head 3, and the buckle assembly 5 is arranged in the cavity two 11 of the buckle head 3; the cavity one 10 and the cavity two 11 are provided with a magnetic attraction component placement cavity 12, and the cavity one 10 is also provided with a hook cavity 100, and the cavity tw...

Embodiment 2

[0045] Embodiment 2, see attached Figure 1~5 and Figure 8 , an automatic magnetic buckle including a buckle body 1, the buckle body 1 is provided with a buckle seat 2, a buckle head 3, a magnetic attraction component 4 and a buckle component 5; the buckle seat 2 is provided with an annular fastening groove 6. The buckle component 5 is mated and fastened with the ring-shaped fastening groove 6 , the magnetic attraction component 4 is respectively set in the buckle seat 2 and the buckle head 3 , and the buckle component 5 is set in the buckle head 3 .

[0046]The buckle body 1 is provided with a cavity one 10 and a cavity two 11, the cavity one 10 is set in the buckle seat 2, the cavity two 11 is set in the buckle head 3, and the buckle assembly 5 is arranged in the cavity two 11 of the buckle head 3; the cavity one 10 and the cavity two 11 are provided with a magnetic attraction component placement cavity 12, and the cavity one 10 is also provided with a hook cavity 100, and...

Embodiment 3

[0050] Embodiment 3, see attached Figure 1~5 and Figure 7 , an automatic magnetic buckle including a buckle body 1, the buckle body 1 is provided with a buckle seat 2, a buckle head 3, a magnetic attraction component 4 and a buckle component 5; the buckle seat 2 is provided with an annular fastening groove 6. The buckle component 5 is mated and fastened with the ring-shaped fastening groove 6 , the magnetic attraction component 4 is respectively set in the buckle seat 2 and the buckle head 3 , and the buckle component 5 is set in the buckle head 3 .

[0051] The buckle body 1 is provided with a cavity one 10 and a cavity two 11, the cavity one 10 is set in the buckle seat 2, the cavity two 11 is set in the buckle head 3, and the buckle assembly 5 is arranged in the cavity two 11 of the buckle head 3; the cavity one 10 and the cavity two 11 are provided with a magnetic attraction component placement cavity 12, and the cavity one 10 is also provided with a hook cavity 100, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com