A concrete slump detection device and its detection method

A detection device and slump technology, applied in the direction of measuring devices, material inspection products, flow characteristics, etc., can solve the problems of affecting concrete slump formation, inaccurate measurement results, easy to touch concrete, etc., to increase the accuracy of measurement Sexuality and convenience, saving manpower, and detecting the effect of labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

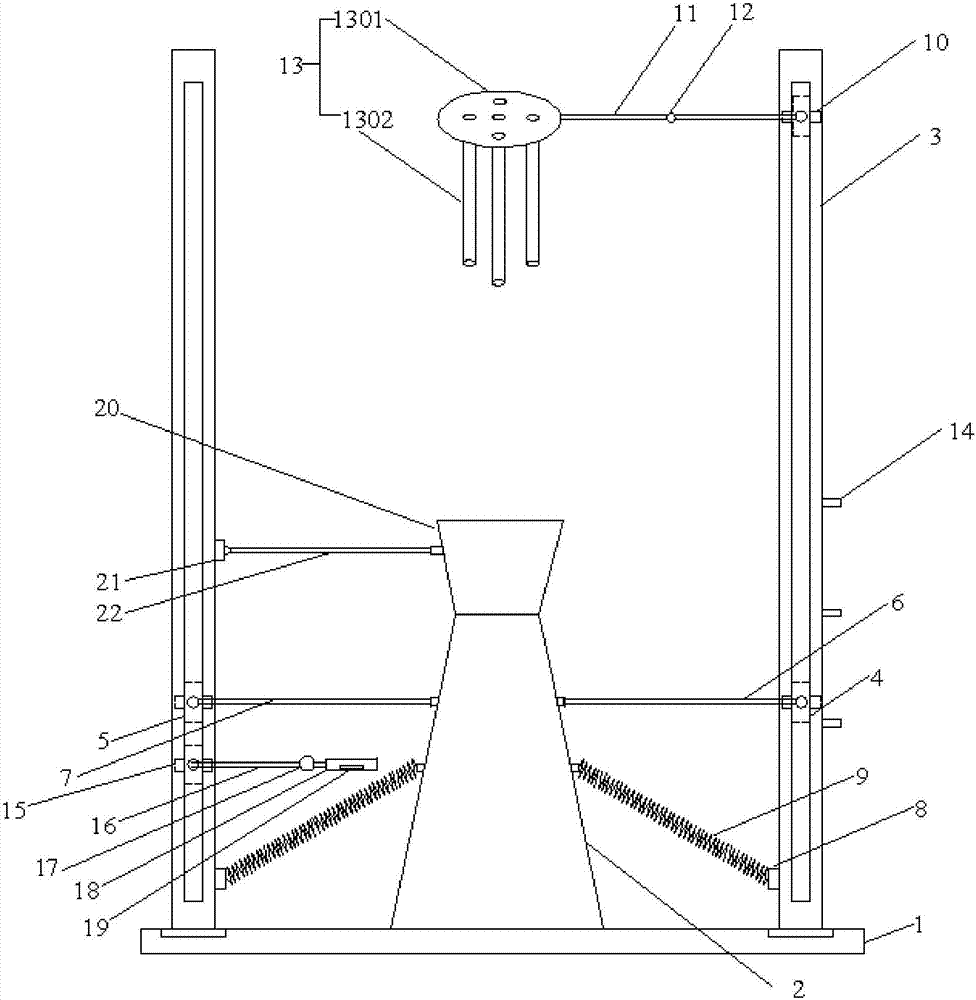

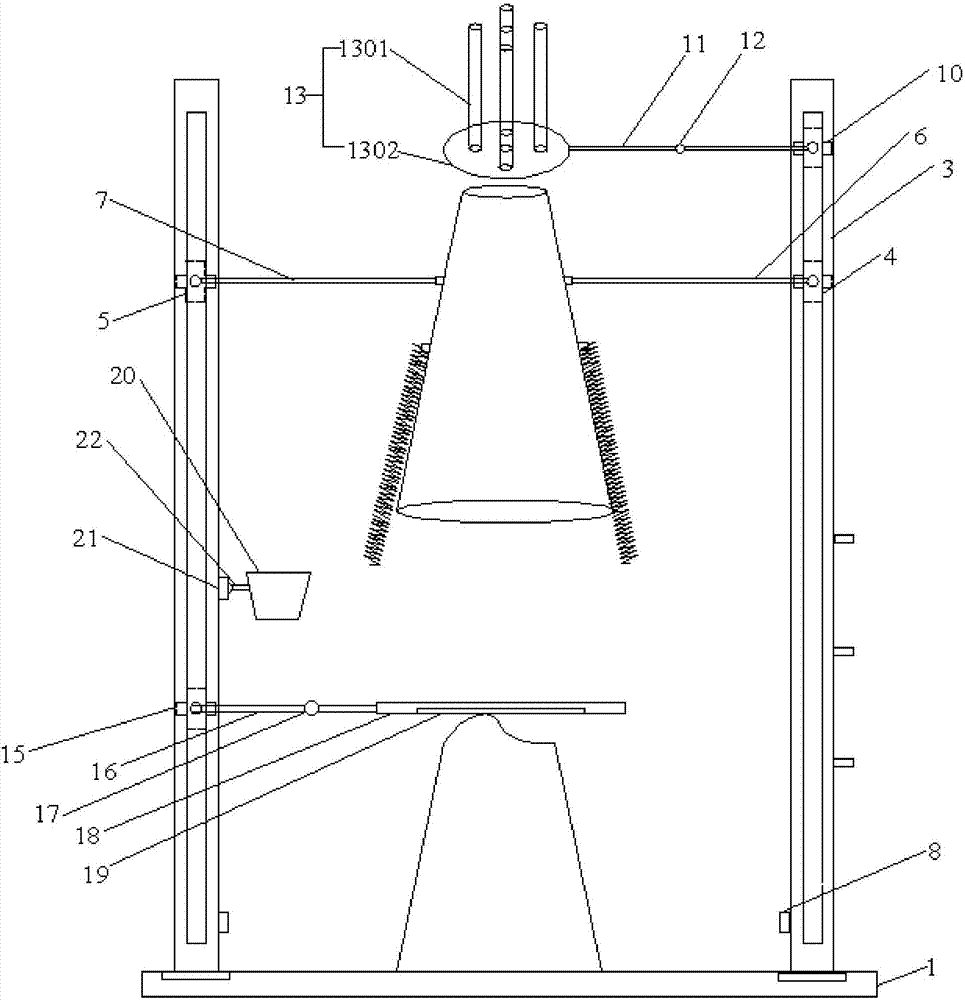

[0031] Such as Figure 1~2As shown, a concrete slump detection device includes a platform 1, a slump bucket 2 and two slide rails 3, the slump bucket 2 is placed at the center of the platform 1, and the two slide rails 3 are arranged On both sides of the slump bucket 2, fixed on the platform 1, that is, two slide rails 3 are arranged on both sides of the center line of the platform 1, the platform 1 has a larger space, and the slump bucket 2 and the two slide rails There is enough space between rails 3 to allow the concrete to slump naturally without any shelter. The two slide rails 3 are respectively provided with a first slide block 4 and a second slide block 5, and the slide rails 3 are provided with a switch for controlling the first slide block 4 and the second slide block 5, and the first slide block 4. The second slider 5 is respectively connected with a first lifting rod 6 and a second lifting rod 7, the side of the slump barrel 2 is provided with a connecting port, t...

Embodiment 2

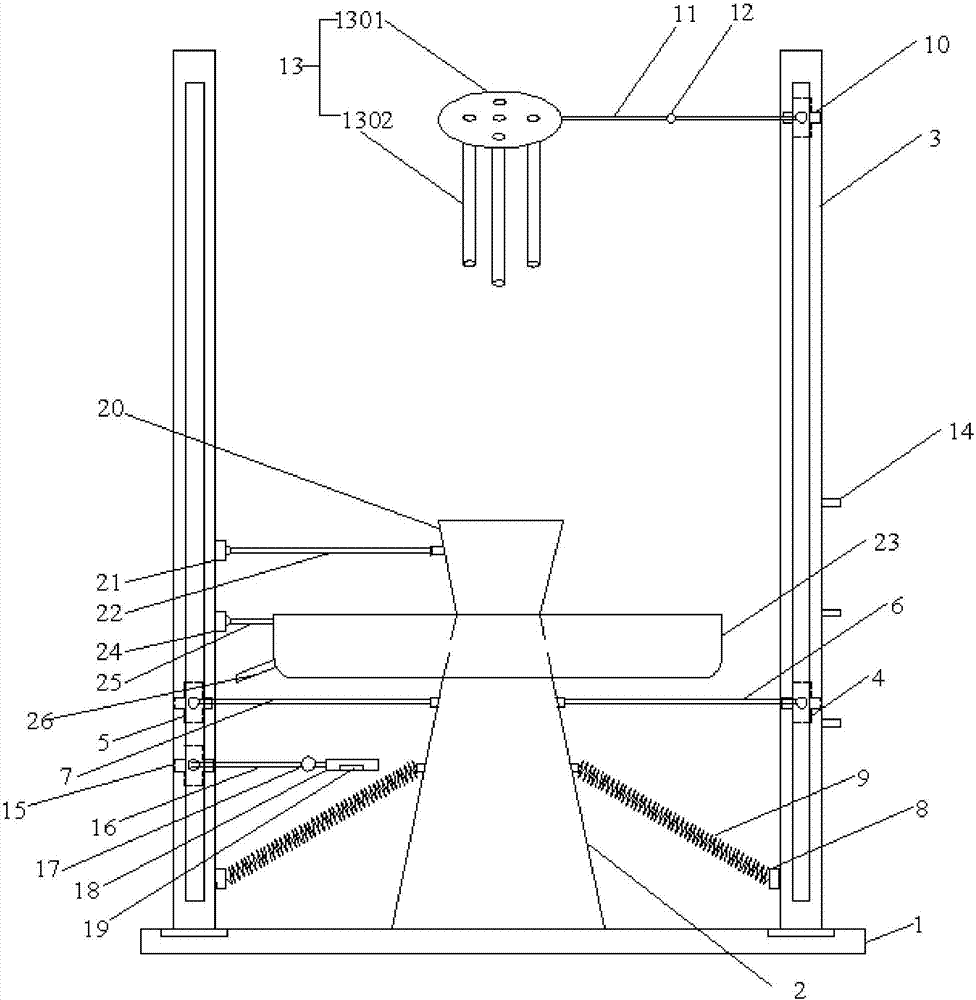

[0039] like Figure 3-5 As shown, the difference between this embodiment and Embodiment 1 is that it also includes an excess material trough 23, which is a U-shaped groove, and a second rotating head 24 is provided on the side of one of the slide rails 3, and the second rotating head 24 is provided on the side of the first slide rail 3. The second rotating head 24 is connected with the fourth connecting rod 25, and the fourth connecting rod 25 is connected with the residual material tank 23, and the side of the residual material tank 23 is provided with an inclined outlet 26. The structure and connection design of the residual material chute 23 can better undertake the excess concrete in the cutting process. There is a gap in the U-shaped groove, which is convenient to tightly trap the slump barrel 2 horizontally, the second rotating head 24 and the fourth connecting rod 25 are convenient for the remaining material tank 23 to trap horizontally or stay away from the slump barre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com