LED light concentration device and parallel exposure machine

A technology of a polymerization device and an LED light source is applied in the field of exposure machines, which can solve the problems of scattered light and inability to use exposure machines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

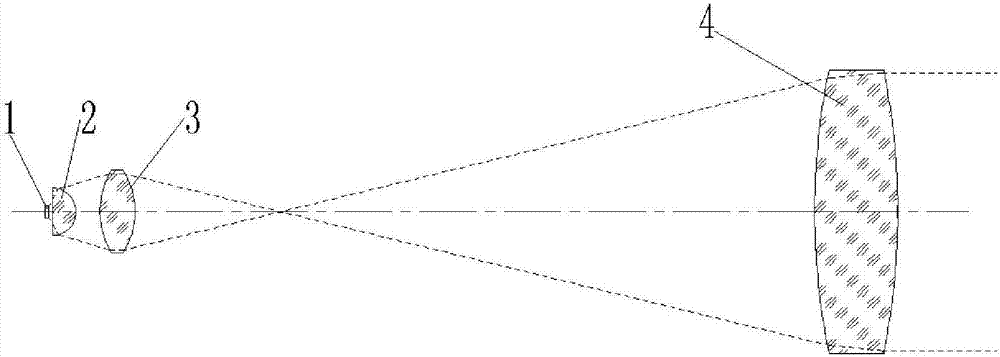

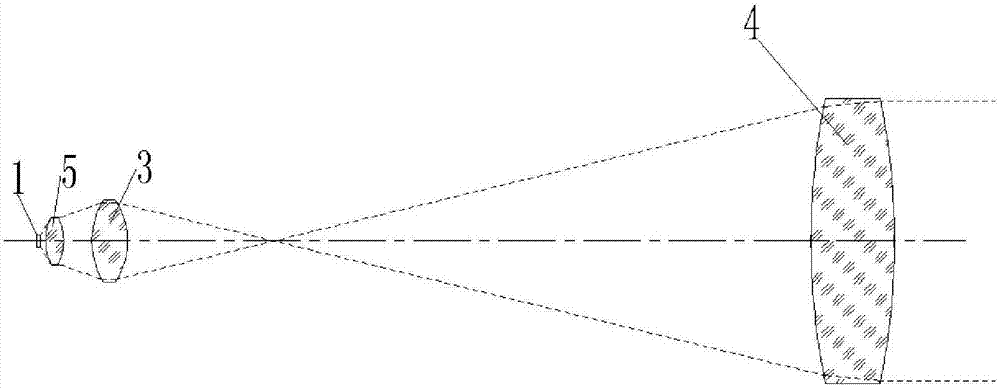

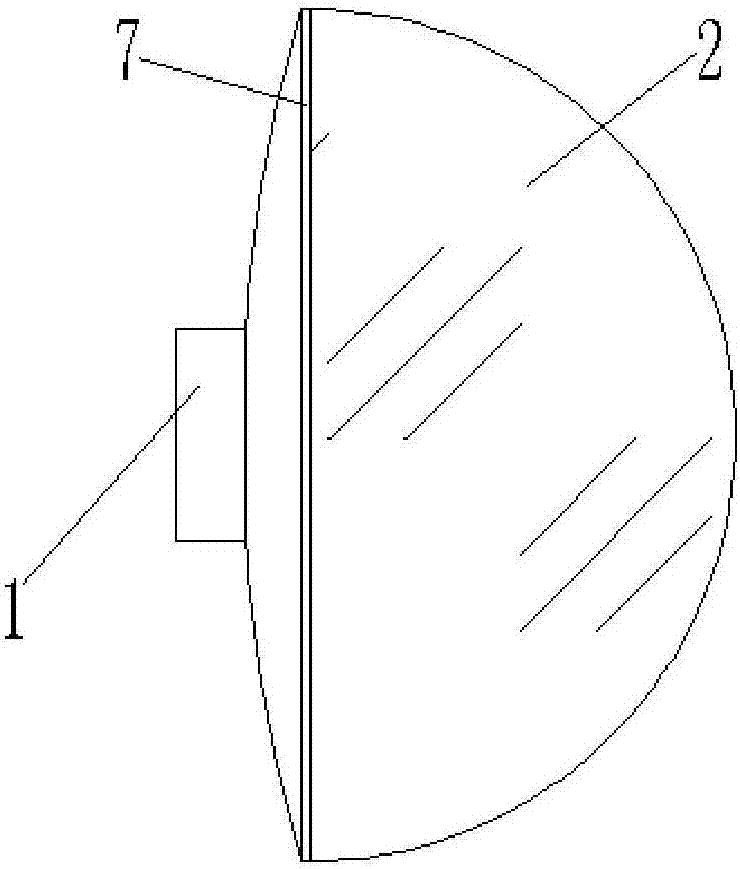

[0034] Such as figure 1 and figure 2 As shown, the embodiment of the present invention provides an LED light aggregation device, including an LED light source, a first lens, a second lens, and a third lens; the first lens, the second lens, and the third lens are arranged in sequence and are located on the same central axis Above, the LED light source faces the first lens, so that the scattered light emitted by the LED light source passes through the first lens, the second lens and the third lens in sequence and becomes uniform parallel light.

[0035]The LED light aggregation device provided by the embodiment of the present invention includes an LED light source and a first lens, a second lens, and a third lens with a light-condensing function; wherein, the first lens, the second lens, and the third lens are arranged at intervals in sequence and Located on the same central axis, the light emitted by the LED light source passes through the first lens, the second lens and the ...

Embodiment 2

[0056] An embodiment of the present invention provides a parallel exposure machine, comprising a plurality of LED light aggregation devices as described above, the plurality of LED light aggregation devices are arranged side by side with each other, and the central axes of the LED light aggregation devices are parallel to each other set up.

[0057] The parallel exposure machine provided by the embodiment of the present invention includes a plurality of LED light aggregation devices described above, wherein the plurality of LED light aggregation devices are closely spaced, and the central axis of each LED light aggregation device is parallel to each other. A parallel light beam can form the total light source of the parallel exposure machine. At this time, projections of different shapes or areas can be formed according to the number and rehearsal method of adjusting the light aggregation devices of LEDs, so as to meet the requirements of exposure machines of different specifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Spherical radius | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com