Electric shock-prevention power supply device

A power supply device and anti-electric shock technology, which is applied in the field of electric power, can solve problems such as easy-to-induced electric shock accidents, failure to supply power normally, and limited plugging force, so as to improve dustproof and waterproof performance, improve stability and safety, and prevent plugging loose connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

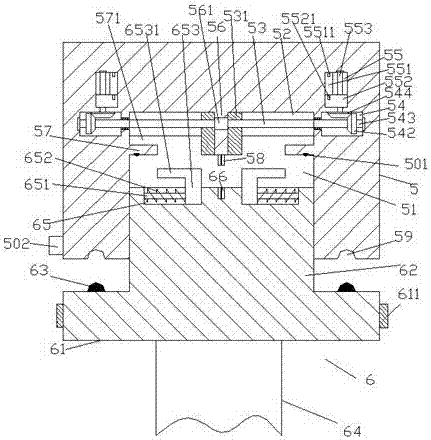

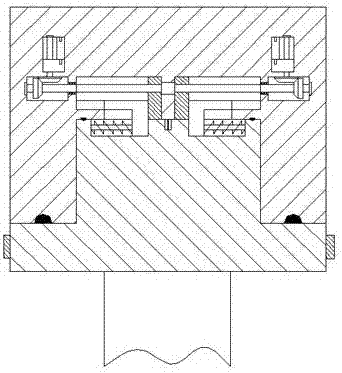

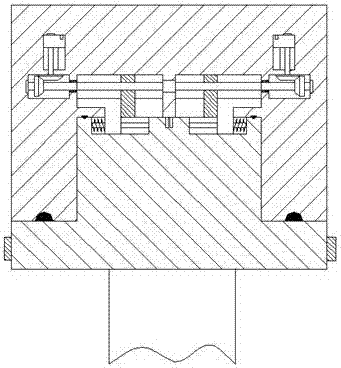

[0022] Such as Figure 1-Figure 4 As shown, a kind of anti-shock power supply device of the present invention includes a socket part 5 and a plug part 6, the inner bottom of the socket part 5 is provided with a cavity 51, and the top of the cavity 51 is provided with first sliding grooves corresponding to the left and right 52. Between the two first sliding grooves 52, there is a spacer 56 extended downwards. The downward extension of the spacer 56 extends into the cavity 51. The first sliding grooves 52 deviate from The socket portion 5 on one side of the spacer 56 is provided with a first control chamber 54, a steering shaft 543 is provided in the first control chamber 54, and a steering shaft 543 is provided in each of the first sliding grooves 52. There is a first screw rod 53, and a push block 531 is helically connected to the first screw rod 53, the inner side of the first screw rod 53 is connected with the driving machine 561, and the first tooth shape is fixed on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com