Bamboo plywood gumming device

A technology of dipping device and bamboo plywood is applied in the direction of impregnating wood, wood impregnating, reed/straw treatment, etc. It can solve the problems of waste of human resources, inability to install automatic operation, inconvenient use, etc., saving human resources and high efficiency. , easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

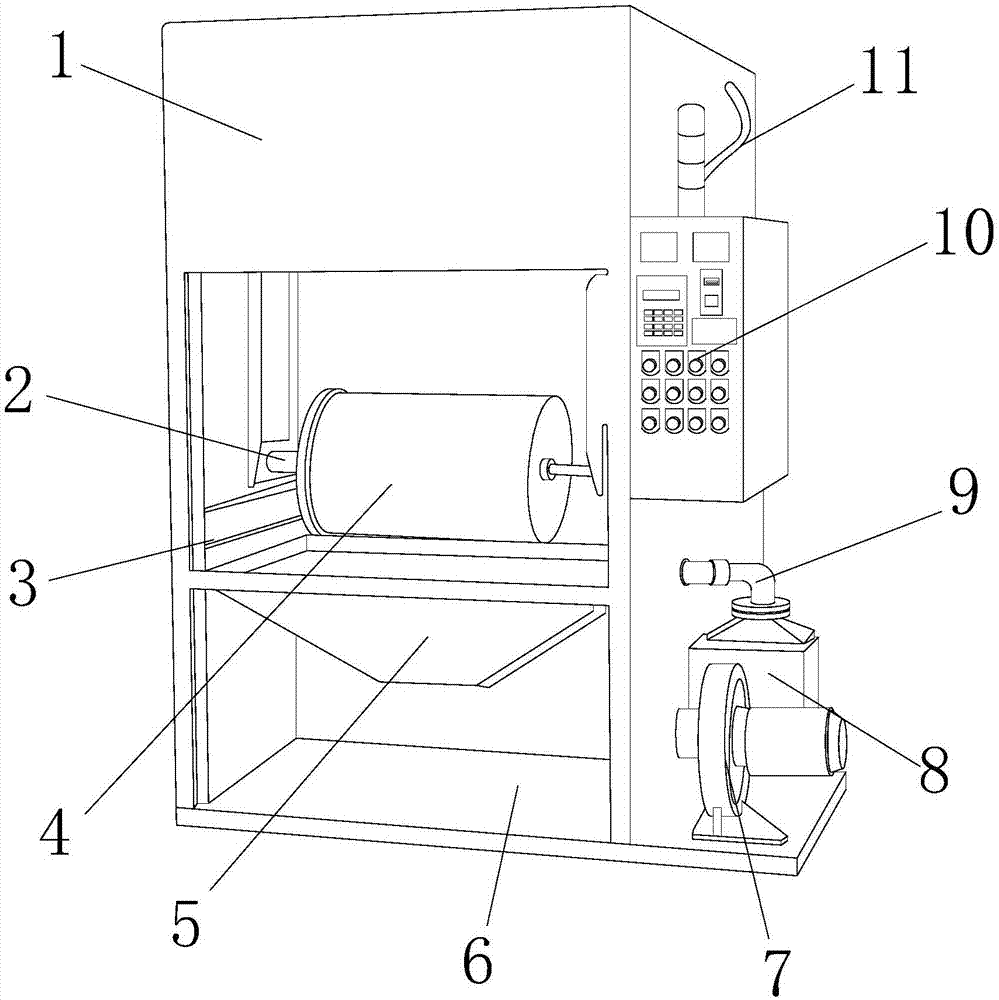

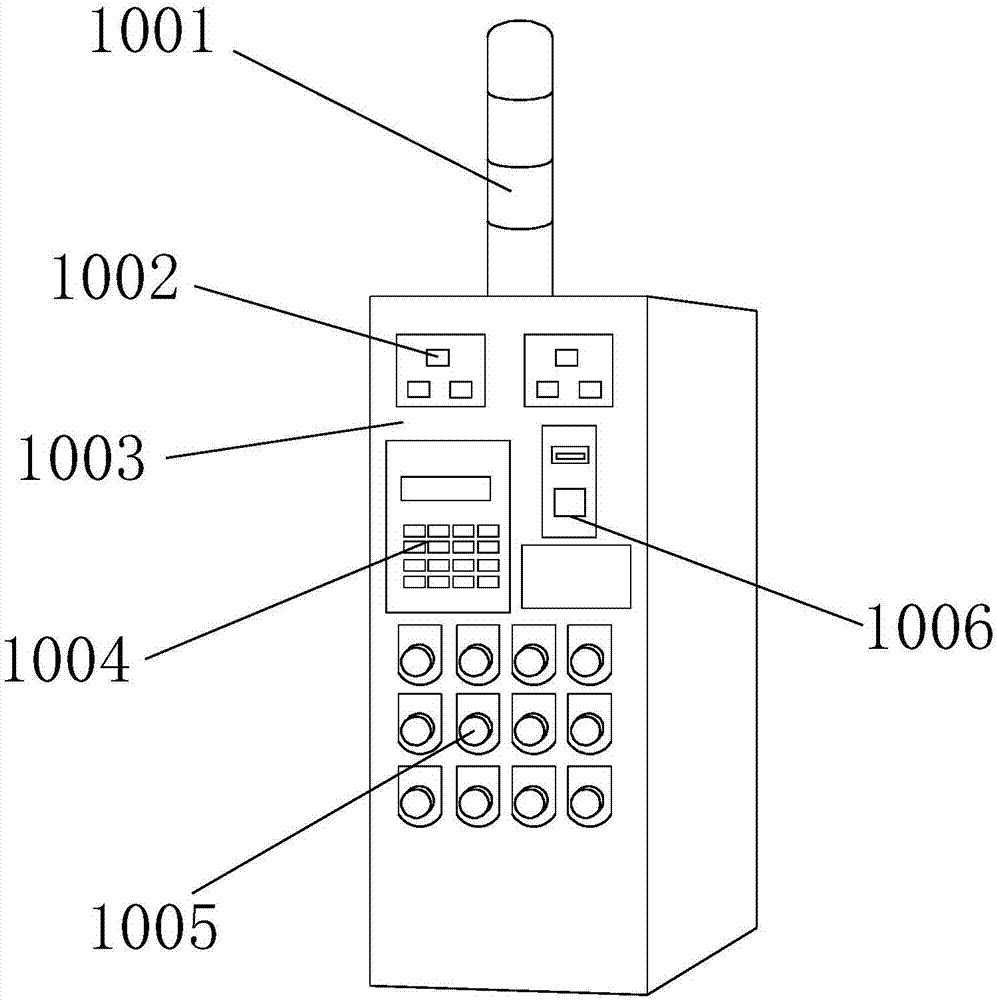

[0018] see Figure 1-Figure 2 , the present invention provides a bamboo plywood dipping device: its structure includes a body 1, a rotating shaft 2, an inner wall 3, a dipping barrel 4, a barrel 5, a base 6, a motor 7, a barrel 8, a hose 9, Electric control box 10, connecting cable 11, the left and right sides of the body 1 are provided with an integral structure of inner walls 3, the base 6 is a rectangular structure and is welded vertically to the bottom of the body 1, and the rotating shaft 2 is nested in the dipped The inside and both ends of the rubber cylinder 4 are respectively connected with the inner wall 3 and have a gap fit. The middle part of the rubber cylinder 5 and the inner wall 3 is welded as an integral structure. The motor 7 is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap