Injection mold and injection molding process for display panel of small household appliances

A technology for display panels and injection molds, which can be applied to household appliances, other household appliances, household components, etc., and can solve problems affecting the production efficiency of display panels, high labor intensity, and complicated injection molding process, so as to reduce labor intensity and facilitate The effect of unloading and changing materials and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

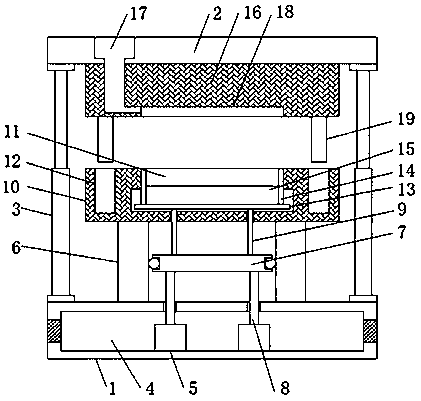

[0020] refer to figure 1 , an injection mold for a display panel of a small home appliance, comprising a fixing seat 1 and a support plate 2, the fixing seat 1 is located directly below the support plate 2, a placement cavity 4 is provided on the fixing seat 1, and two push rods are installed in the placement cavity 4 Motor 5, the two sides of the top of fixed base 1 are respectively fixedly installed with vertical cylinder 3 and fixed plate 6, and wherein cylinder 3 is positioned at the both sides of fixed plate 6, and the piston rod of cylinder 3 is fixedly connected with support plate 2, and fixed plate 6 slides and is connected with the movable plate 7 that is arranged horizontally, and the bottom both sides of movable plate 7 is all connected with the telescoping rod 8 that vertically arranges, and telescopic rod 8 is connected with the output shaft of push rod motor 5, and the movable plate 7 Both sides of the top are connected with a vertical movable rod 9, and the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com