Antiskid transport box

A non-slip, box technology, applied in the direction of transportation and packaging, rigid containers, containers, etc., can solve the problems of easy smashing, poor stability, and inability to carry boxes, etc., to prevent mutual scratches, high stability, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

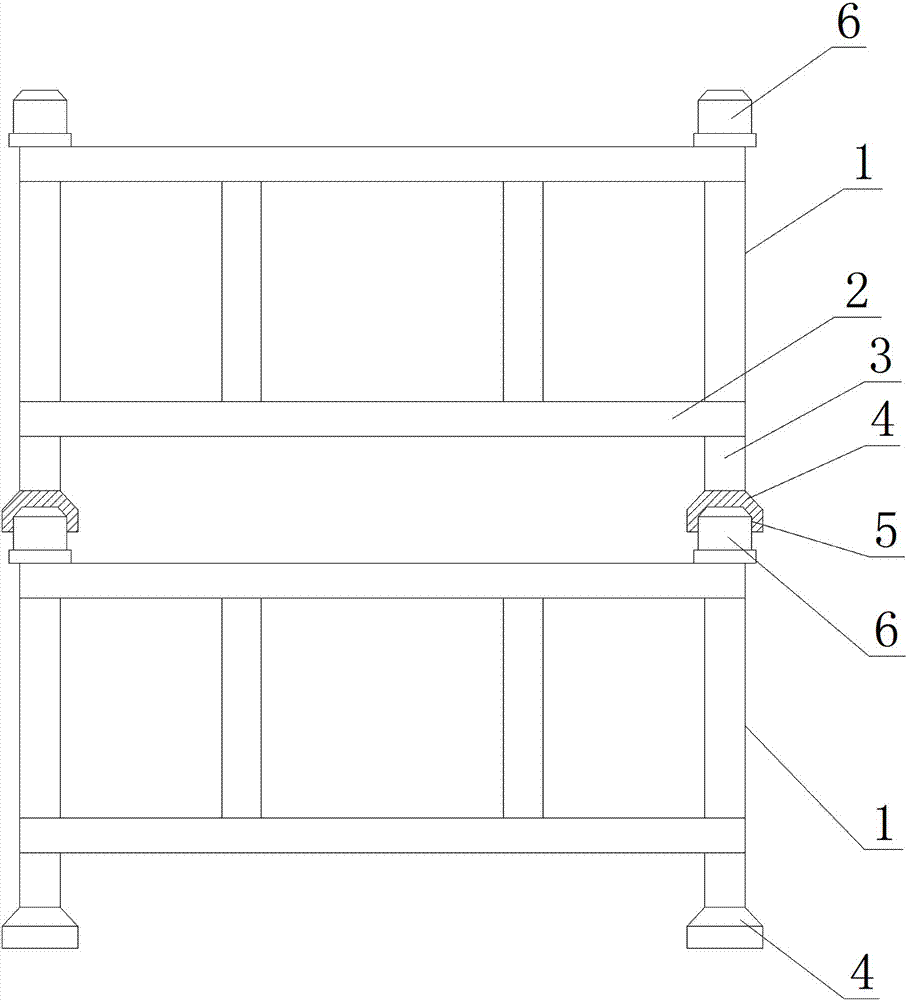

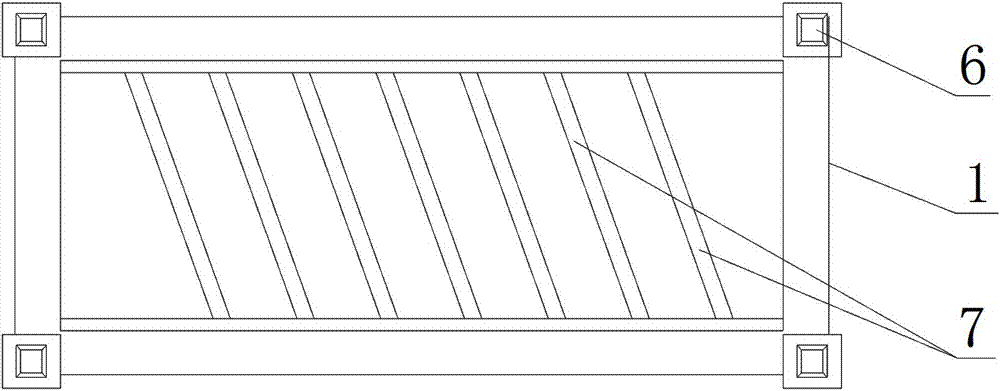

[0014] Such as Figure 1~2 Shown, a kind of anti-skid box for transportation, it comprises a plurality of casings 1, and casing 1 is rectangular shape, is positioned at the four corners of bottom plate 2 of casing 1 and is all fixedly provided with supporting legs 3, and the four supporting legs 3 Bottoms are all provided with fixed block 4, and the bottom of fixed block 4 is provided with positioning groove 5, is positioned at the four corners of box body 1 top and all is fixed with positioning platform 6, and positioning platform 6 is square platform. Due to the existence of the legs 3, a gap is formed between the bottom plate of the upper casing 1 and the top of the lower casing 1, which ensures that the fork of the forklift can be inserted into the gap, and facilitates the transfer of the casing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com