Tea leaf washing device

A cleaning device and tea technology, which are applied in the direction of pre-extraction tea treatment, etc., can solve the problems of increased production cost, complicated operation, low cleaning efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

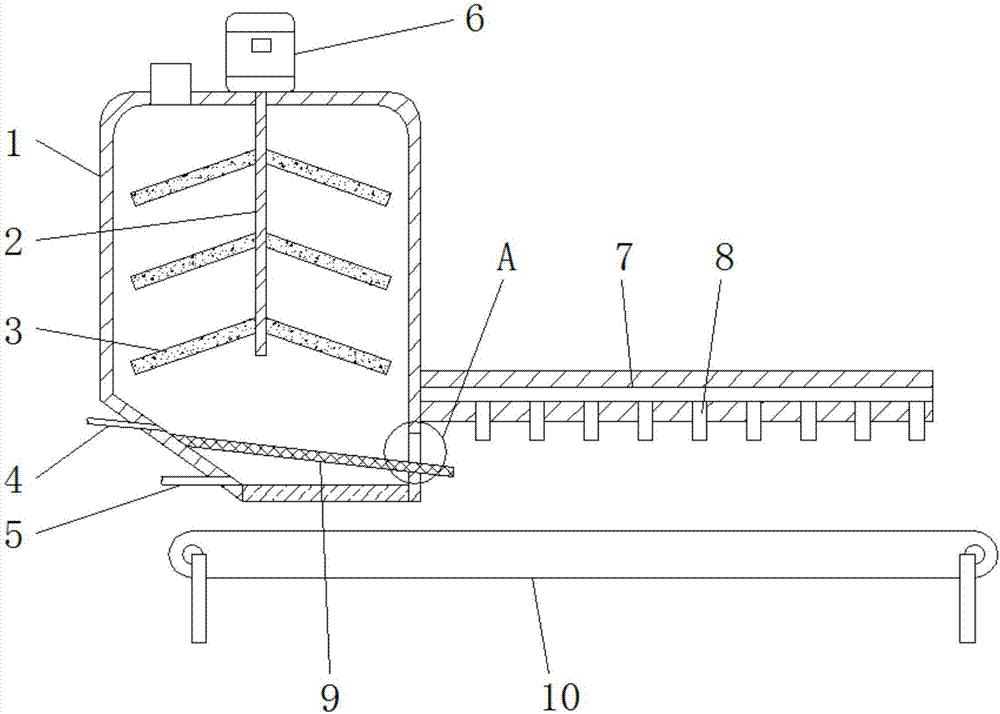

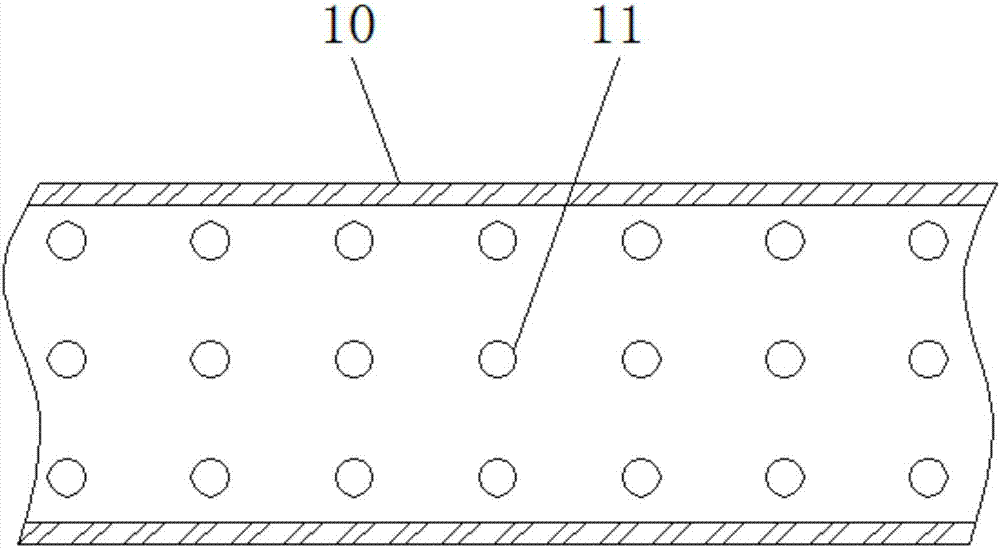

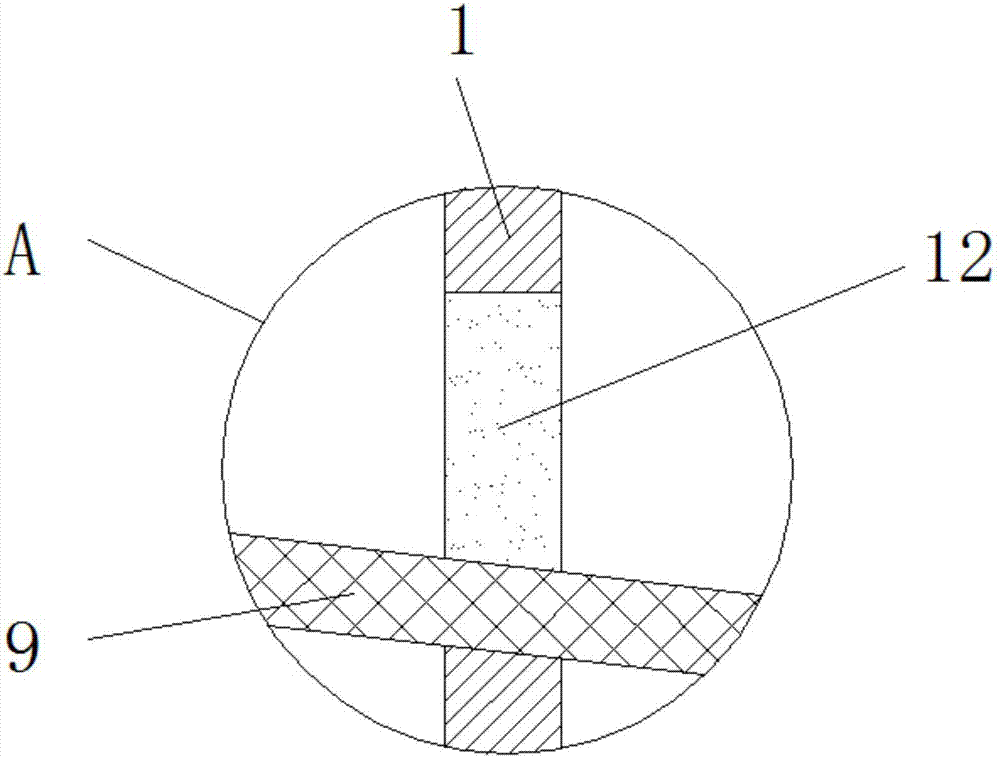

[0017] Such as Figure 1-Figure 3 As shown, a tea cleaning device mainly includes a cleaning tank 1, a rotating rod 2, a stirring blade 3, a water inlet pipe 4, a drain pipe 5, a motor 6, a spray pipe 7, a spray port 8, a net plate 9, and a conveyor belt 10. , The net port 11 and the sealed door 12, the top of the cleaning tank 1 is connected with the motor 6, and the motor 6 is connected with the stirring blade 3 through the rotating rod 2. The right side of the bottom of the cleaning tank 1 is an inclined bottom plate, and the cleaning tank 1 and The spray pipe 7 is installed vertically. This arrangement facilitates the discharge of tea from the bottom of the cleaning tank 1. The installation structure of the mixing blade 3 is inclined installation, and the mixing blade 3 is arranged equidistantly on both sides of the rotating rod 2. The mixing blade 3 is provided with three Layer, the stirring blade 3 is arranged to play the role of stirring and cleaning the tea, which is be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com