Wire feeding device for spring processing

A wire feeding device and wire feeding technology are applied in wire processing, spring manufacturing from wire, application, etc., which can solve the problems of center position change, lower processing accuracy, and different alignment degrees, and achieve noise reduction, transmission stability and Improved rigidity and reduced wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

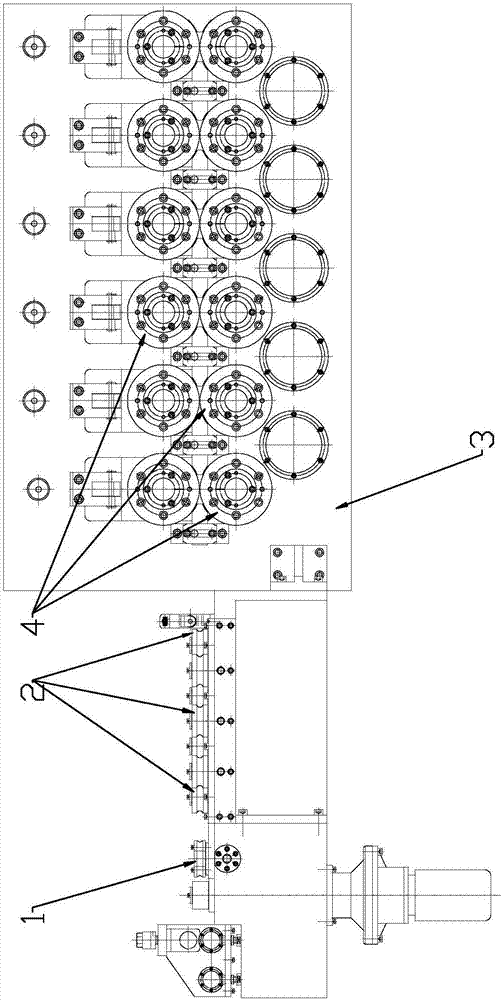

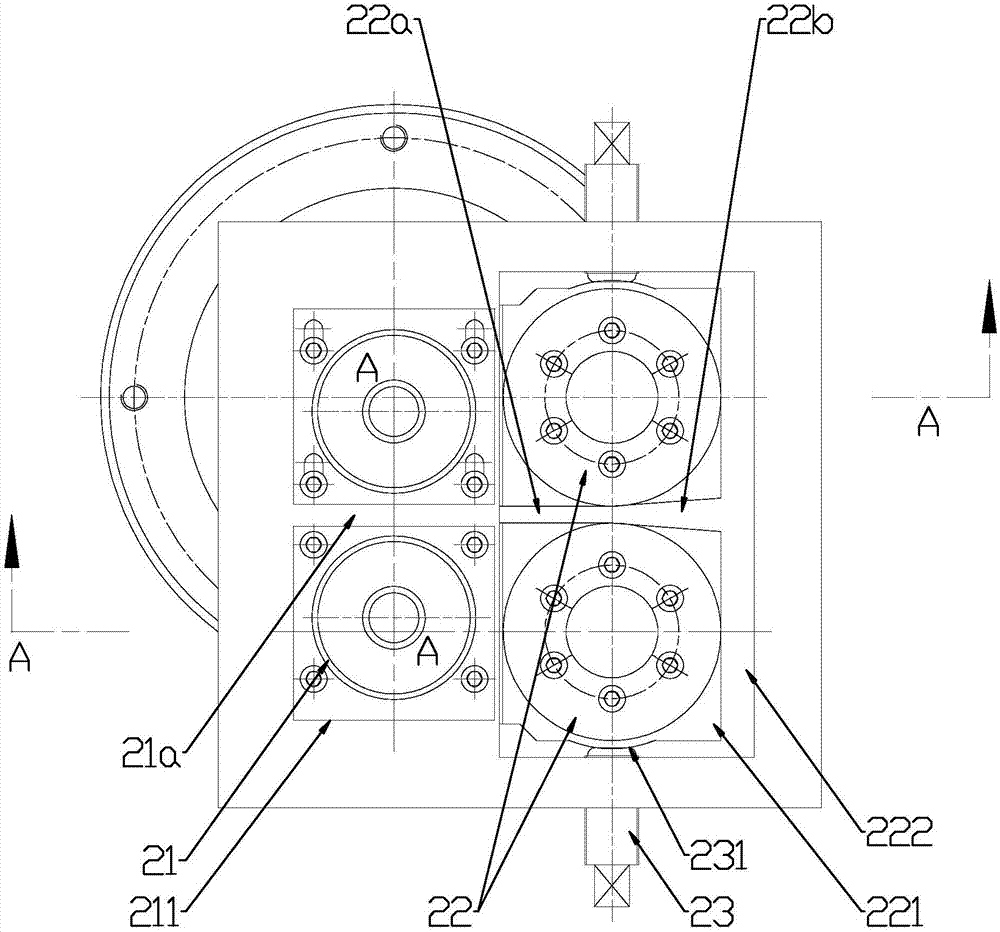

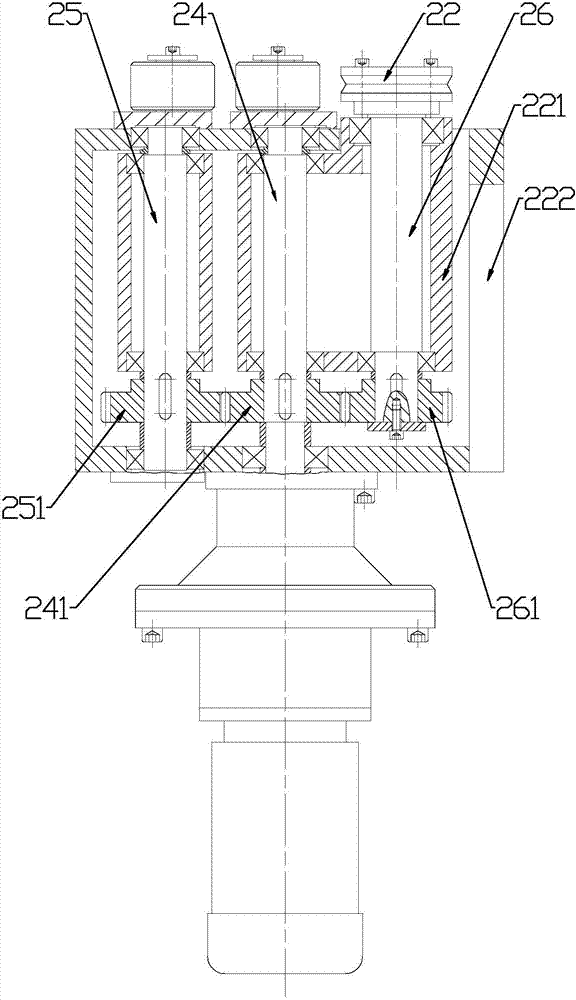

[0040] The wire feeding device used for spring processing in this embodiment, combined with figure 1 , a wire wheel 1, a straightening mechanism 2, a reduction box 3 and several groups of wire feeding wheels 4 located in the reduction box 3 are arranged in sequence, the steel wire raw material to be processed is wound on the wire wheel 1, and the wire wheel 1 rotates, and the The steel wire is sent into the straightening mechanism 2; when the steel wire is sent into the straightening mechanism 2, the combined Figure 2-Figure 3 , the straightening mechanism 2 includes a pair of predetermined wheels 21, a pair of grooved wheels 22 and a pair of rotating shafts 23, and a pair of predetermined wheels 21 are installed on a group of pre-bearing seats 211, between the upper and lower two predetermined wheels 21 There is a pre-feed groove 21a that allows the steel wire sent out by the wire wheel 1 to pass through; a pair of sheaves 22 are installed on a set of straightening bearing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com