Method for rapidly drawing steel-structure pitched roof model

A technology for steel structures and sloping roofs, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve the problems that commands cannot be parameterized, the drawing process is complicated, and cannot be changed, so as to improve drawing efficiency and simplify drawing. Process, effect of shortened time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

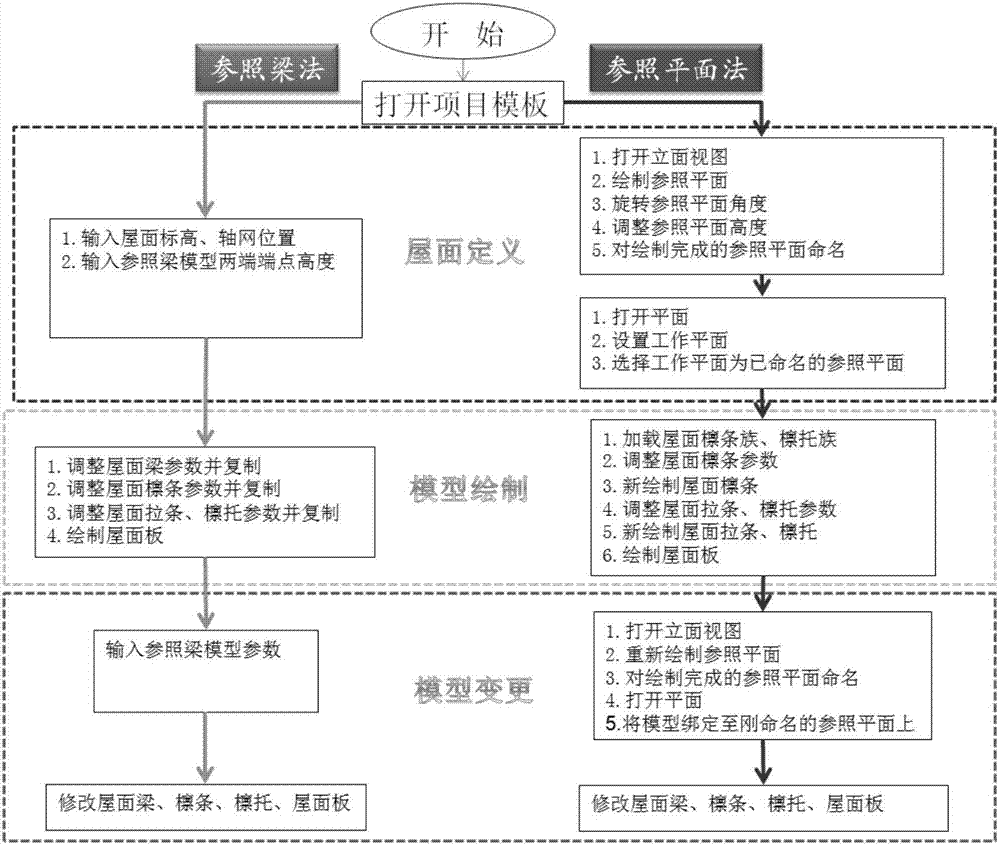

[0059] This scheme uses the reference beam method, which completely avoids the shortcomings of non-parameterization, inability to change, no connection between planes, and cumbersome process in the reference plane method. Designers no longer need to complete complicated work and improve the efficiency of roof model drawing. At the same time, the operation items for drawing the roof by the traditional reference plane method are reduced from 15 to 7, and the operation items are reduced from 6 to 2 when changing. For the specific process comparison, see figure 1 . The drawing time is shortened by more than 60% compared with the traditional method, the drawing efficiency is high, and it is not easy to make mistakes.

[0060] The method of using the reference plane has many defects. By using the parameterizable reference beam model surface instead of the reference plane, the steps are as follows:

[0061]A method for quickly drawing a steel structure slope roof model, the steps ar...

Embodiment 2

[0088] Embodiment 2 is basically the same as Embodiment 1, and may also include step G after step F, model change;

[0089] 1) Input the new parameters of the height of the end points at both ends of the reference beam model;

[0090] 2) Correspondingly adjust the parameters and positions of each model element on the roof to complete the model change.

[0091] Through the presetting of the scheme, the drawing process is finally simplified, the time for drawing the steel structure slope roof model is shortened, the accuracy rate is improved, and the parametric change of the steel structure slope roof model is realized, so as to improve the drawing efficiency of the steel structure slope roof model the goal of.

Embodiment approach

[0093] Through the above scheme, the steel structure sloping roof drawing template can be constructed specifically, and the specific implementation method is as follows:

[0094] 1. Define the default structural roof elevation, grid and center reference plane.

[0095] 2. Draw the reference beam model, define the default elevation as the structural roof elevation, the default elevation of the starting and ending points, the extension of the starting and ending points, material, structural use and other parameters.

[0096] 3. Draw the default roof beam model, define the working plane as the surface of the reference beam model, the default elevation of the start and end points, the extension of the start and end points, the material, the structural purpose and other parameters.

[0097] 4. Draw 2 default purlins, define the working plane as the surface of the reference beam model, the default elevation of the starting and ending points, the extension of the starting and ending ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com