Grooved nail polisher

A nail and groove bottom technology, used in manicure or pedicure tools, clothing, applications, etc., can solve the problems of easy slippage and abrasion of muscles, inconvenience to carry, large size, etc.

Pending Publication Date: 2017-12-22

梁平原

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

It is bulky and inconvenient to carry around. It is difficult to accurately locate and control the force when using it. It is easy to slip and bruise muscles, and the efficiency is low.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

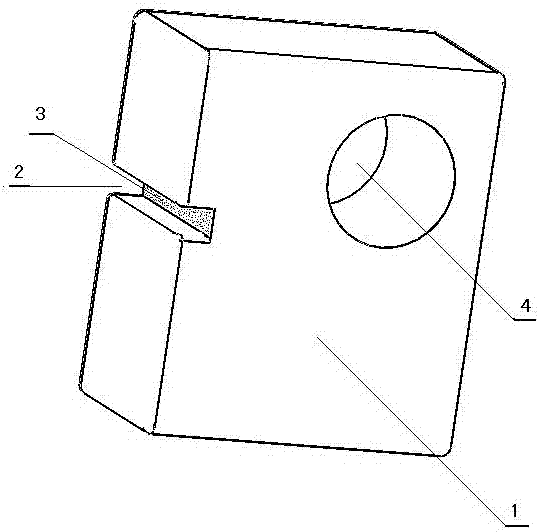

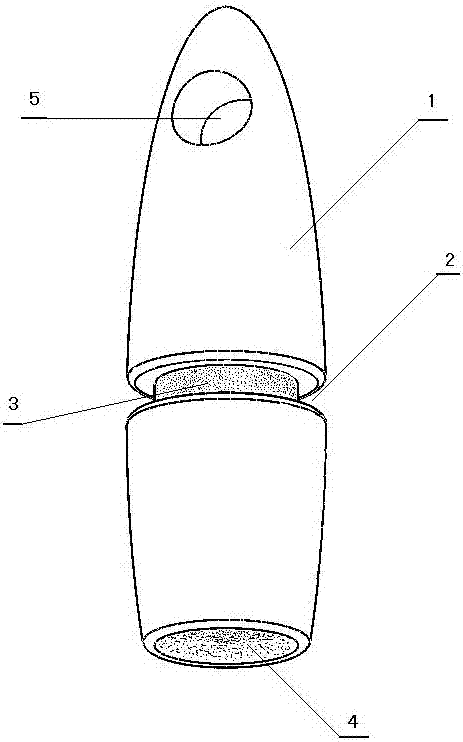

[0021] That is, a grooved nail grinder with a columnar grinding body.

[0022] which is figure 2 The embodiment shown.

[0023] Among the figure 1 is a grinding body, i.e. a columnar grinding body, 2 is an annular groove at the waist of the nail grinding cylinder, 3 is the sand surface at the bottom of the groove, 4 is the concave surface at the bottom of the cylinder, and 5 is the hanging hole of the nail grinding. .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention is a kind of nail grinder, which is characterized in that grooves are engraved on the hand-held object, the bottom of the groove is a concave surface, the width of the groove is such that the nails can be pinched smoothly, and it can prevent the muscles of the fingertips from entering. The depth of the groove is limited to the suitable nail touching the bottom of the groove. Existing nail grinders are generally strip-shaped or rod-shaped files, which are all plane files in nature. It is bulky and inconvenient to carry around. It is difficult to accurately locate and control the force when using it, and it is easy to slip and bruise muscles. The present invention allows the nails to fall into the groove when grinding the nails, and separates them from the muscles. The force is easy to grasp. The original reciprocating action of the nail grinding can be changed to a combination of rotation and reciprocating action, which is not easy to slip and scratch the muscles. It has high efficiency and is easy to carry. Can save using nail clippers.

Description

technical field [0001] The invention relates to a nail grinder, in particular to a grooved nail grinder. Background technique [0002] Existing nail grinders are generally strip-shaped or rod-shaped files, which are all plane files in nature. It is bulky and inconvenient to carry around. It is difficult to accurately locate and control the force when using it. It is easy to slip and bruise muscles, and its efficiency is low. Contents of the invention [0003] In order to solve the above problems, the present invention has invented a groove nail grinder. When grinding nails, let the nails pinch into the groove and separate from the muscles. The strength is easy to grasp, the efficiency is high, and it is easy to carry, which can save the use of nail scissors. [0004] A nail grinder, which is characterized in that a groove is engraved on a hand-held object, and the bottom of the groove is a concave surface. Fingernails are limited to the bottom of the groove. [0005] T...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A45D29/04A45D29/12

CPCA45D29/04A45D29/12A45D2029/045

Inventor 梁平原

Owner 梁平原

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com