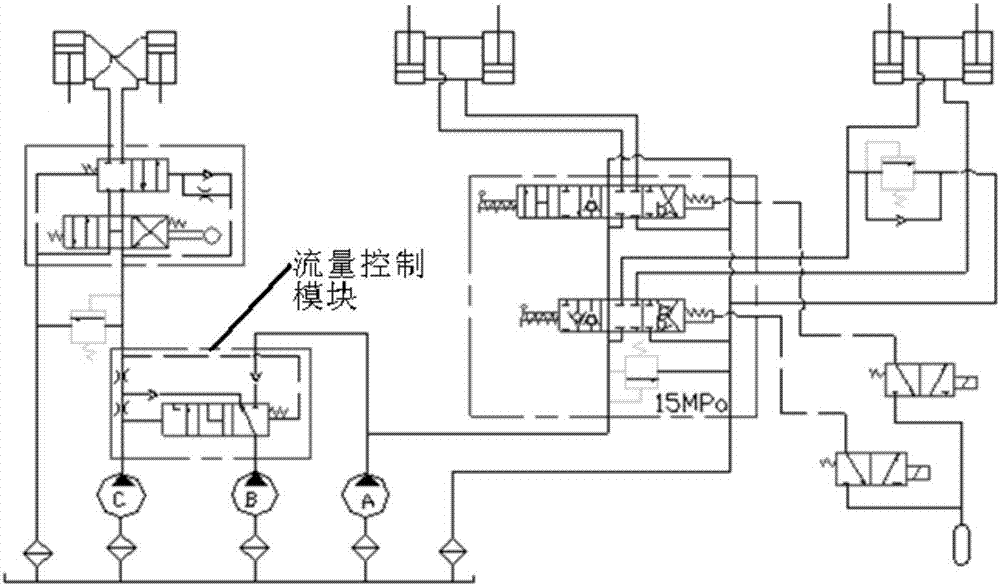

Forward flow control work multi-way valve structure

A technology of flow control and multi-way valve, which is applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problems of complex structure, inability to meet the requirements of complex composite actions, high cost, etc., and achieve flexible and satisfying distribution modes. The effect of complex compound movement requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

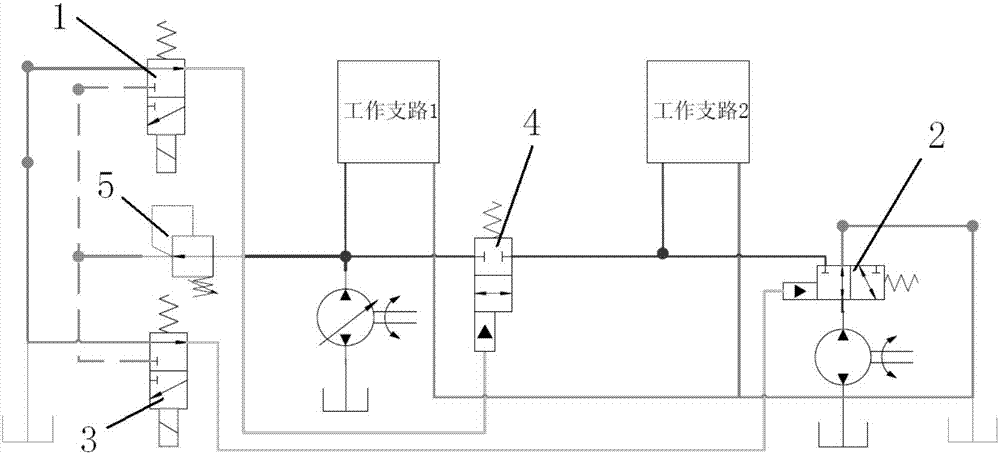

[0019] A multi-way valve structure with positive flow control, including proportional solenoid valve A1, unloading valve 2, proportional solenoid valve B3, confluence valve 4, pressure reducing valve 5, wherein proportional solenoid valve A(1) and proportional solenoid valve B(3) adopts 24V DC power supply, and controls the current of the solenoid valve in the range of 0-700mA through PWM, so as to proportionally control the output pressure of the control chamber of the solenoid valve. The pilot oil inlet and outlet of pressure reducing valve 5 are connected to the oil inlet and outlet of proportional solenoid valve A1, the control chamber of proportional solenoid valve A1 is connected to the control chamber of unloading valve 2 spool, and the oil inlet and outlet of unloading valve 2 are connected to the oil inlet and outlet of variable pump respectively. It is connected with the total oil return; the pilot oil inlet and outlet of the pressure reducing valve 5 are connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com