Pipe joint structure

A technology of pipe joints and pipe bodies, which is applied in the direction of pipe/pipe joint/fitting, sleeve/socket connection, passing components, etc., which can solve the problems of low production efficiency, high cost, and difficult processing, and improve product production efficiency , easy to process, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

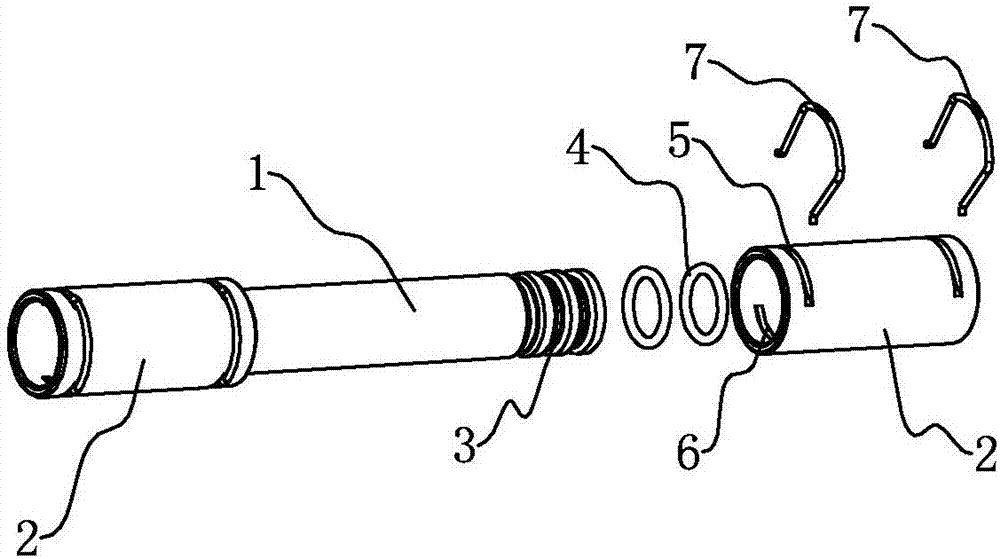

[0012] refer to figure 1 , as a pipe joint structure in the first embodiment of the present invention, it includes a pipe body 1 and a connecting sleeve 2, the connecting sleeve 2 is set on the end of the pipe body 1, and a plurality of grooves 3 are provided at the end of the pipe body 1, The groove 3 is installed with a sealing ring 4 that cooperates with the inner wall of the connecting sleeve to seal. The side of the connecting sleeve 2 has corresponding first and second strip holes 5, 6, and a snap ring 7 passes through the first , The second bar-shaped holes 5, 6 and the pipe body 1 are clamped and fixed. Both ends of the connecting sleeve 2 are provided with the first and second strip-shaped holes 5 and 6, so that the pipe body can be fixed at both ends of the connecting sleeve to realize the extension of the pipe body.

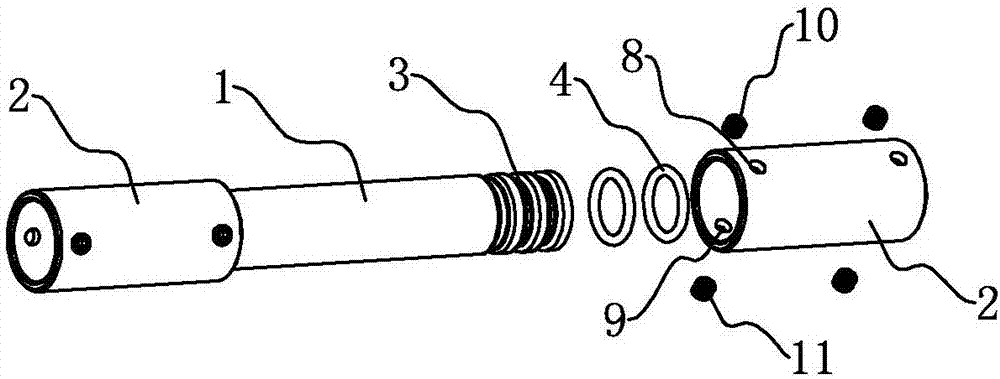

[0013] refer to figure 2 , as a pipe joint structure according to the second embodiment of the present invention, it includes a pipe body 1 and a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com