Full-automatic bulb assembly assembler

A ball head assembly, assembly machine technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problem that the quality of the dust cover cannot be well guaranteed, the automobile control arm cannot be assembled, and the dust ring cannot be installed. issues, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

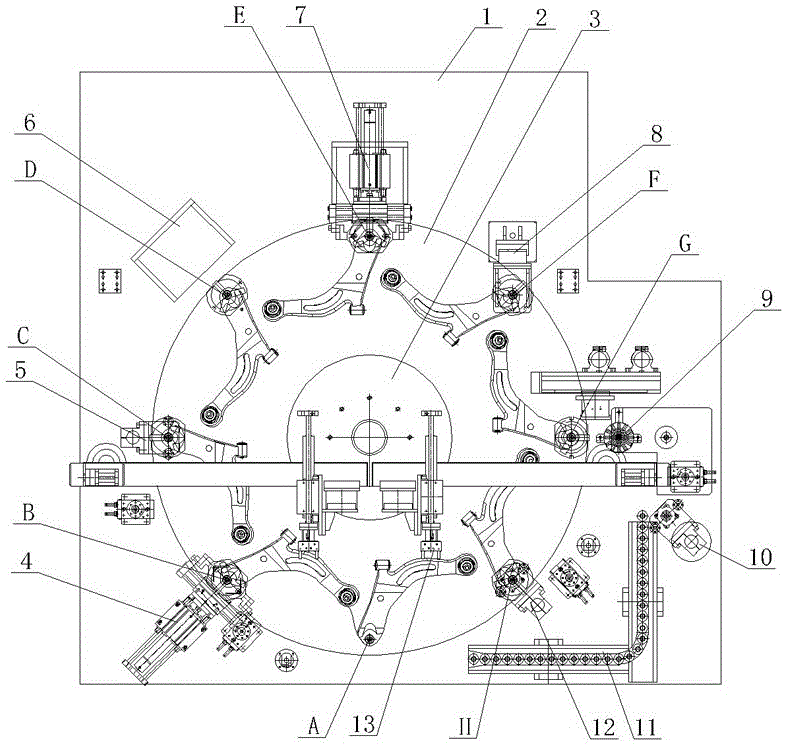

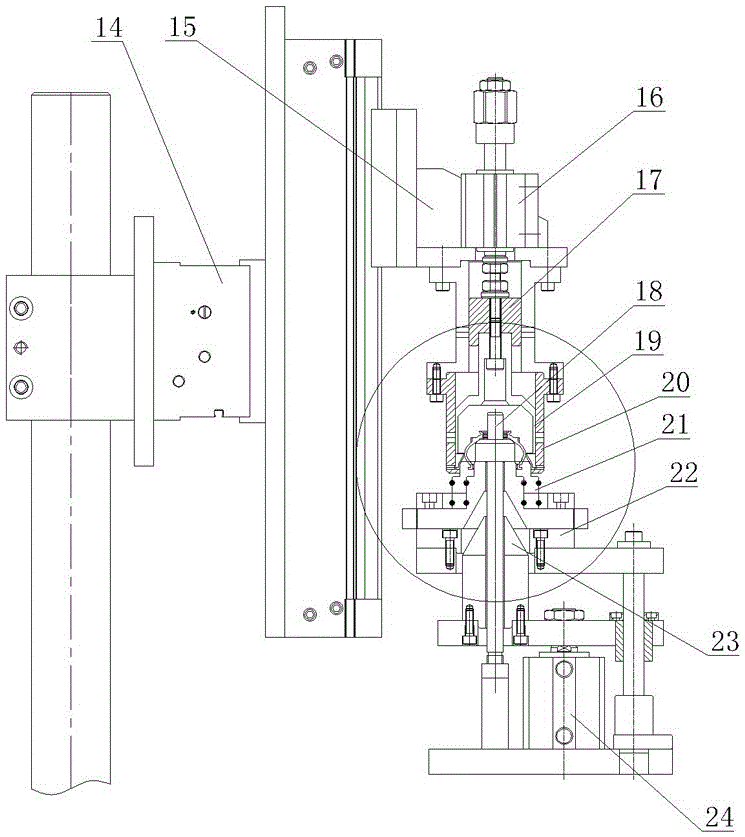

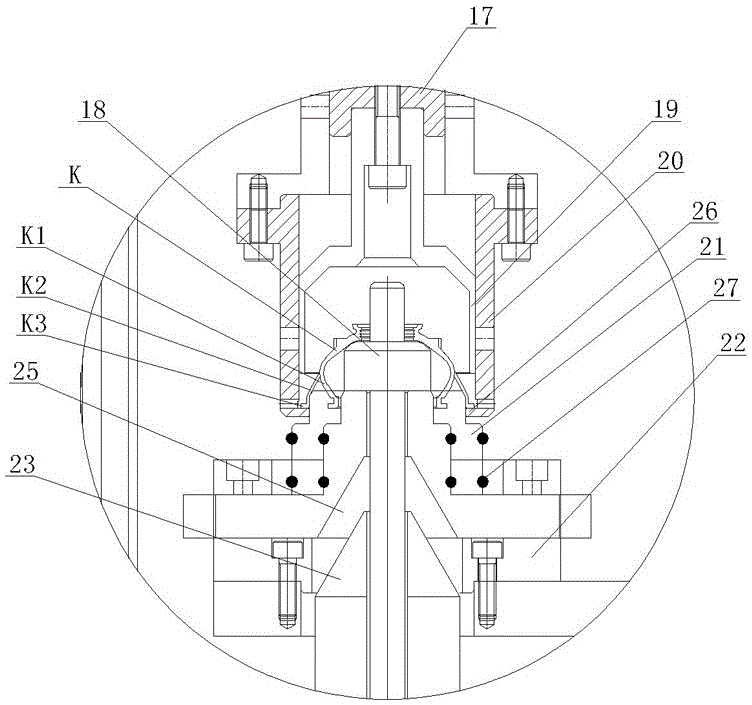

[0013] As shown in the figure, the automatic ball head assembly assembly machine of the present invention includes a workbench 1 and large and small disks arranged above the workbench 1. The large disk 2 is set for indexing and rotating, and the upper circumference of the large disk 2 is set. There are product loading and unloading station A, ball pin uprighting and neck guard installation station B (corresponding to the workbench with the ball pin uprighted part and neck guard loading part 4), shaft retaining ring installation station C (corresponding to the workbench There are shaft retaining ring loading parts 5), ball pin righting and rotating torque test station D (corresponding workbench is equipped with ball pin righting parts and ball pin rotating torque test part 6), ball pin swing torque testing station Position E (corresponding to the ball pin swing torque test part 7 on the workbench), ball pin quantitative oiling station F (corresponding to the ball pin oiling part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com