Weft yarn detection method and weft yarn detection device for air-jet loom

A technology of air-jet loom and detection method, which is applied in looms, weaving, textiles and papermaking, etc., and can solve problems such as failure to respond to the use of weft brakes, failure to issue effective warnings for weft sagging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

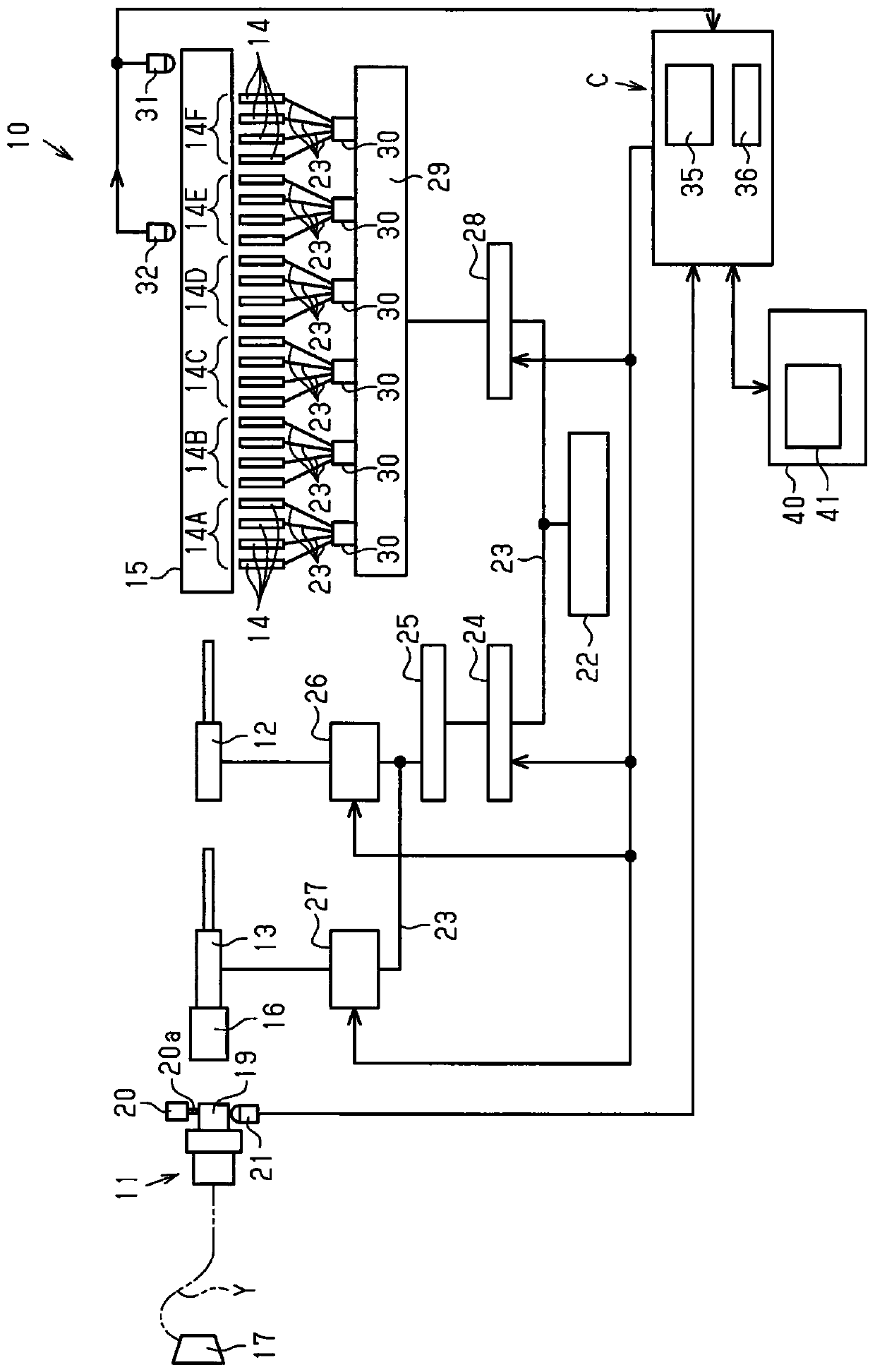

[0022] The following combination Figure 1 to Figure 6 c describes an embodiment that actualizes the present invention.

[0023] Such as figure 1 As shown, the weft inserting device 10 of the air-jet loom includes a weft accumulating device 11, a main nozzle 12, a serial nozzle 13 arranged on the upstream side of the main nozzle 12, and a plurality of sub-nozzles arranged on the downstream side of the main nozzle 12. Groups 14A-14F, reed 15. On the reed 15, a plurality of rows of reed teeth having guide recesses are arranged along the weft insertion direction. The tandem nozzle 13 is provided with a weft brake 16 . Each of the sub-nozzle groups 14A to 14F is composed of four sub-nozzles 14 .

[0024] The weft yarn accumulating device 11 winds and stores the weft yarn Y supplied from the weft yarn bobbin 17 serving as a yarn supplying section around a length measuring drum 19 . The weft accumulating device 11 has a locking pin 20 a that is driven by an electromagnetic sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com