Weft insertion device of air-jet loom

A weft insertion device and air-jet loom technology, which is applied in looms, textiles, textiles and papermaking, etc., can solve problems such as excessive air consumption, inability to achieve high-speed weft insertion, and large distance between auxiliary nozzles and reeds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

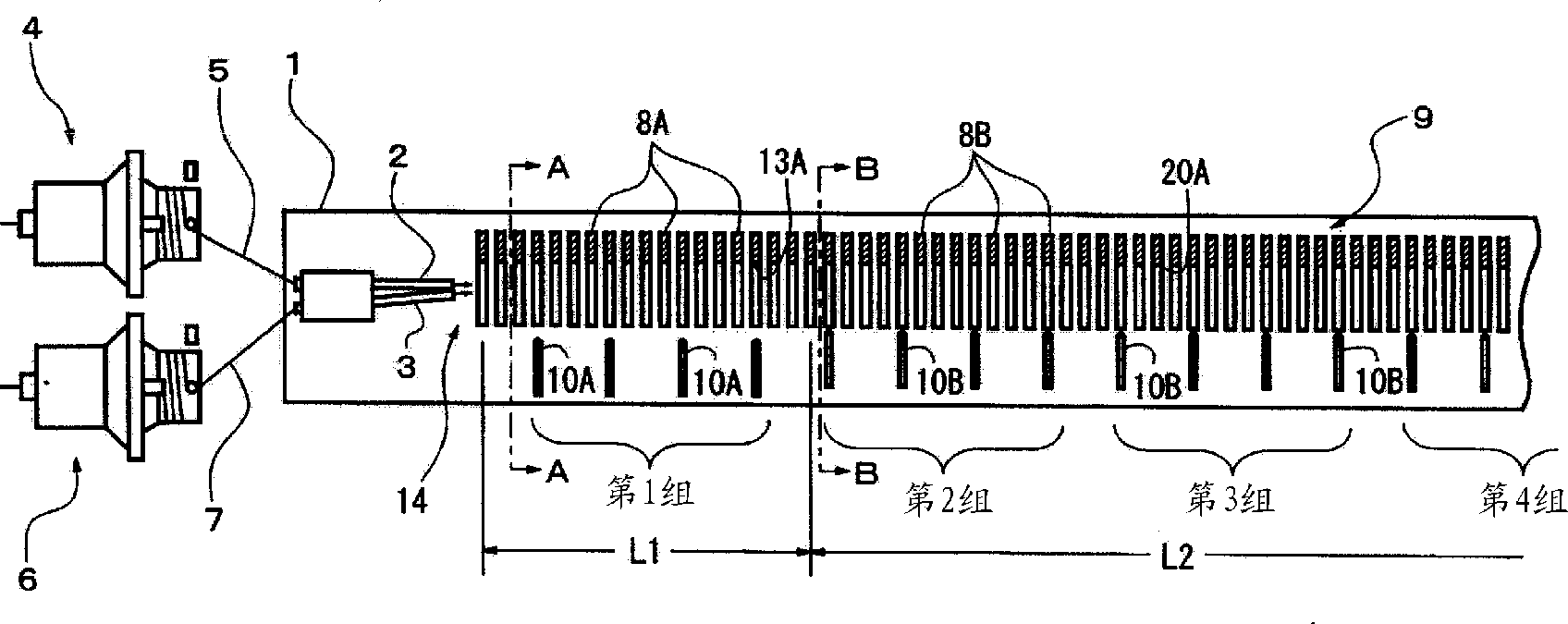

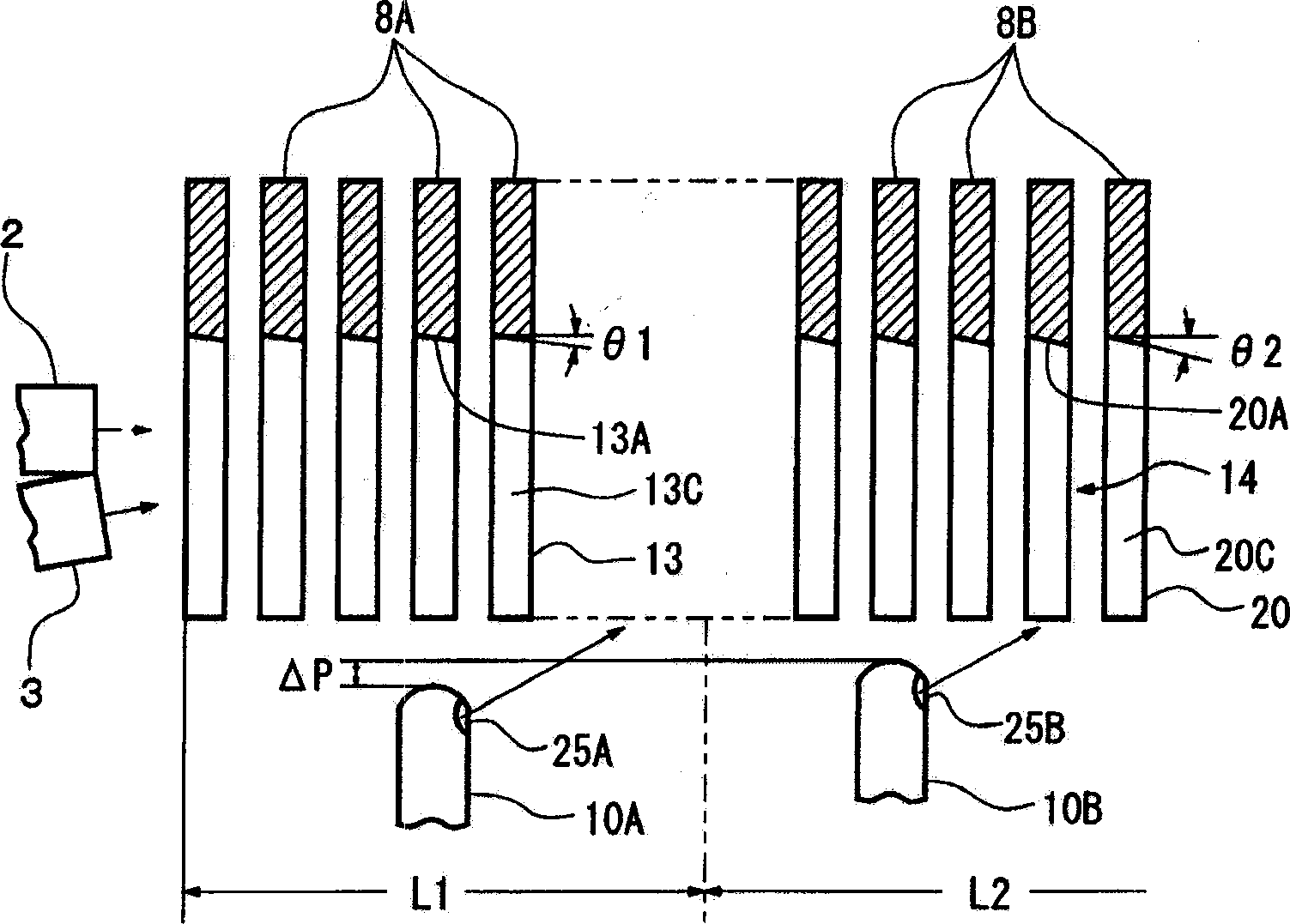

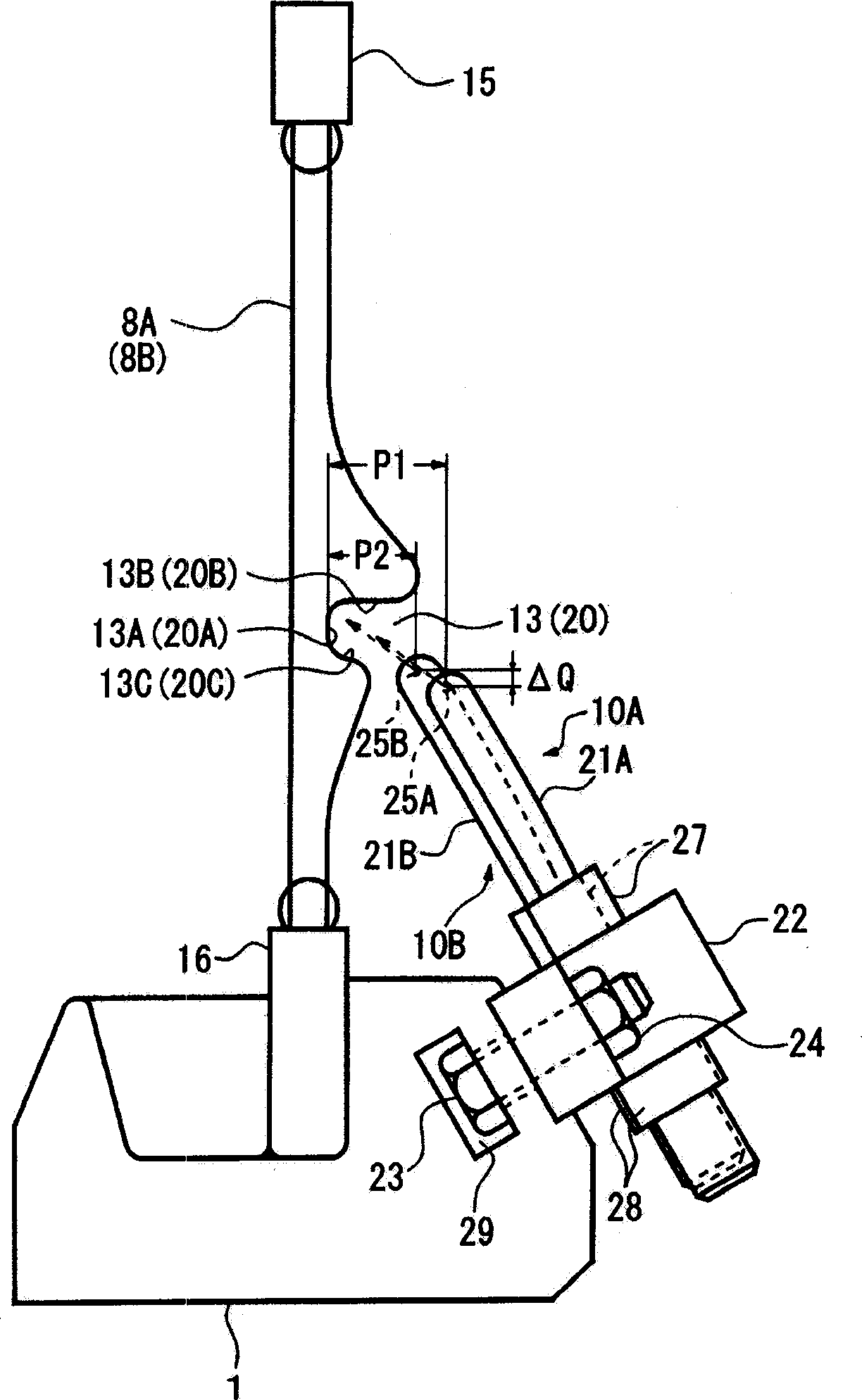

[0022] The following will refer to Figure 1 to Figure 6 The weft insertion device of the air jet loom according to the first embodiment of the present invention will be described. In the following description, the air jet loom will only be referred to as a loom from below. Reference figure 1 , Shows the weft insertion device of the air jet loom, the lower side of the figure corresponds to the front of the loom, where the woven cloth is picked up, and the upper side of the figure corresponds to the back of the loom, where it is released Warp.

[0023] The weft insertion device includes two weft insertion nozzles 2, 3 installed on the sley 1 of the loom. The weft insertion nozzle 2 extends parallel to the weft insertion direction, and the weft insertion nozzle 3 is slightly inclined with respect to the weft insertion direction, so that the air ejected from the nozzle 3 is slightly directed toward the rear of the loom. The weft yarn 5 drawn out from the weft tube (not shown) and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com