Process and stretching device for holding a weft thread

A stretching device and weft yarn technology, applied in the field of stretching devices, can solve the problems of deformation of reed teeth, improper formation of intermediate spaces, and disturbances, etc., and achieve the effects of reliable clamping, changing and shrinking fabric width, and avoiding deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] best practice

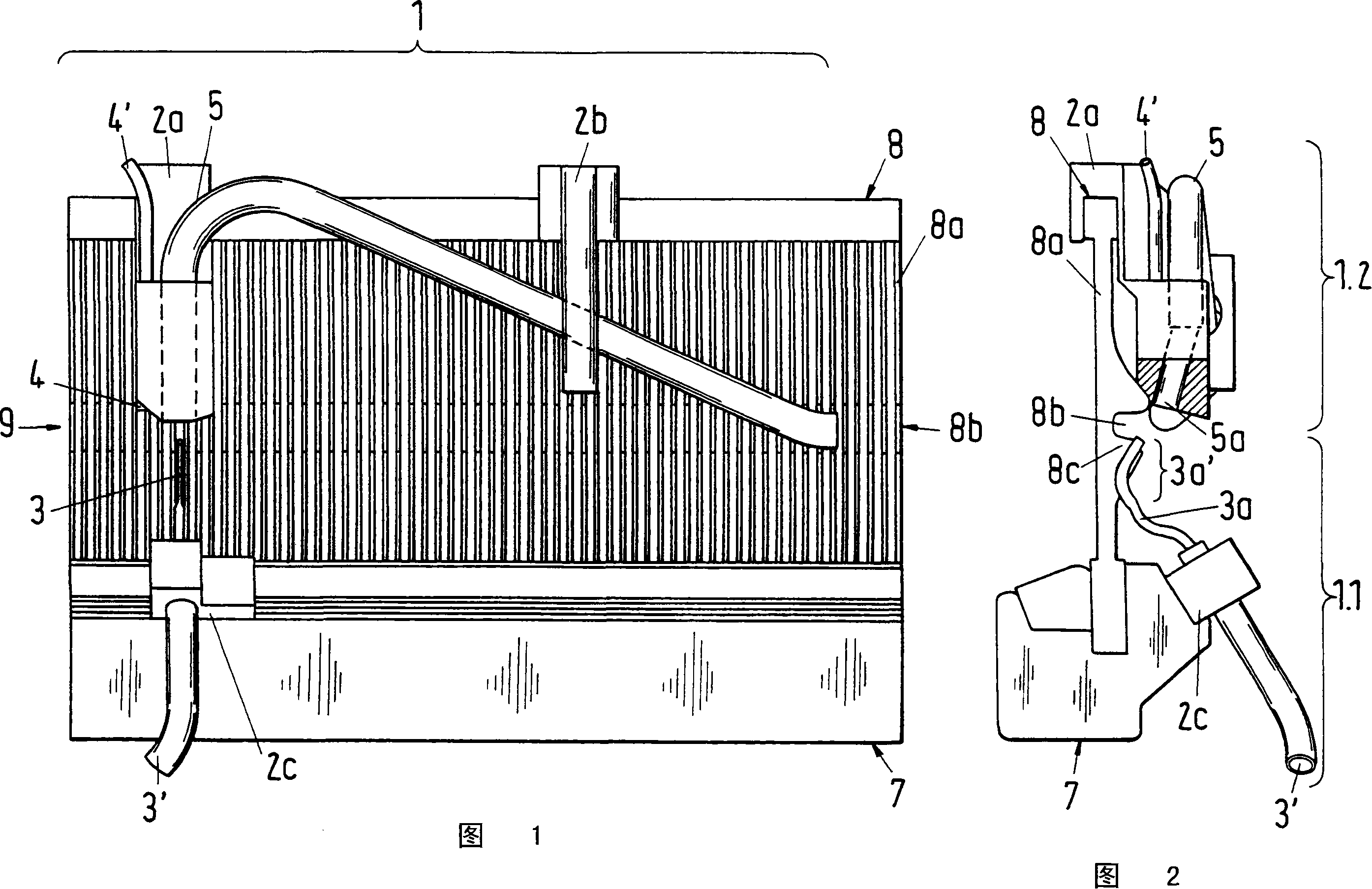

[0021] Shown in accompanying drawings 1 and 2 is the embodiment of the stretching device of the present invention for clamping the weft thread introduced into an air-jet loom provided with a reed 8 . The steel reed 8 includes a plurality of reed teeth 8a, such as shown in FIG. 1 , and the steel reed 8 is placed on the sley 7 . The stretching device according to the invention comprises a capture part 1.2 with a capture channel 5 and a nozzle part 1.1 with a nozzle 3 having a nozzle opening whose blowing direction is offset from the weft insertion direction 9. With the aid of the nozzle 3 , the end portion of the weft thread on the capture side can deviate from the weft insertion direction 9 and be blown into the receiving opening 5 a of the capture channel 5 . As shown in Fig. 2, the receiving opening 5a may be arranged side by side with the nose of the upper reed.

[0022] In addition, the stretching device 1 comprises at least one fixed part for fixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com