Temple edge ironing device of cotton flannel jet loom

An air-jet loom and temple technology, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of quality decline, shortened reed service life, low efficiency, etc. Cloth demand, the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

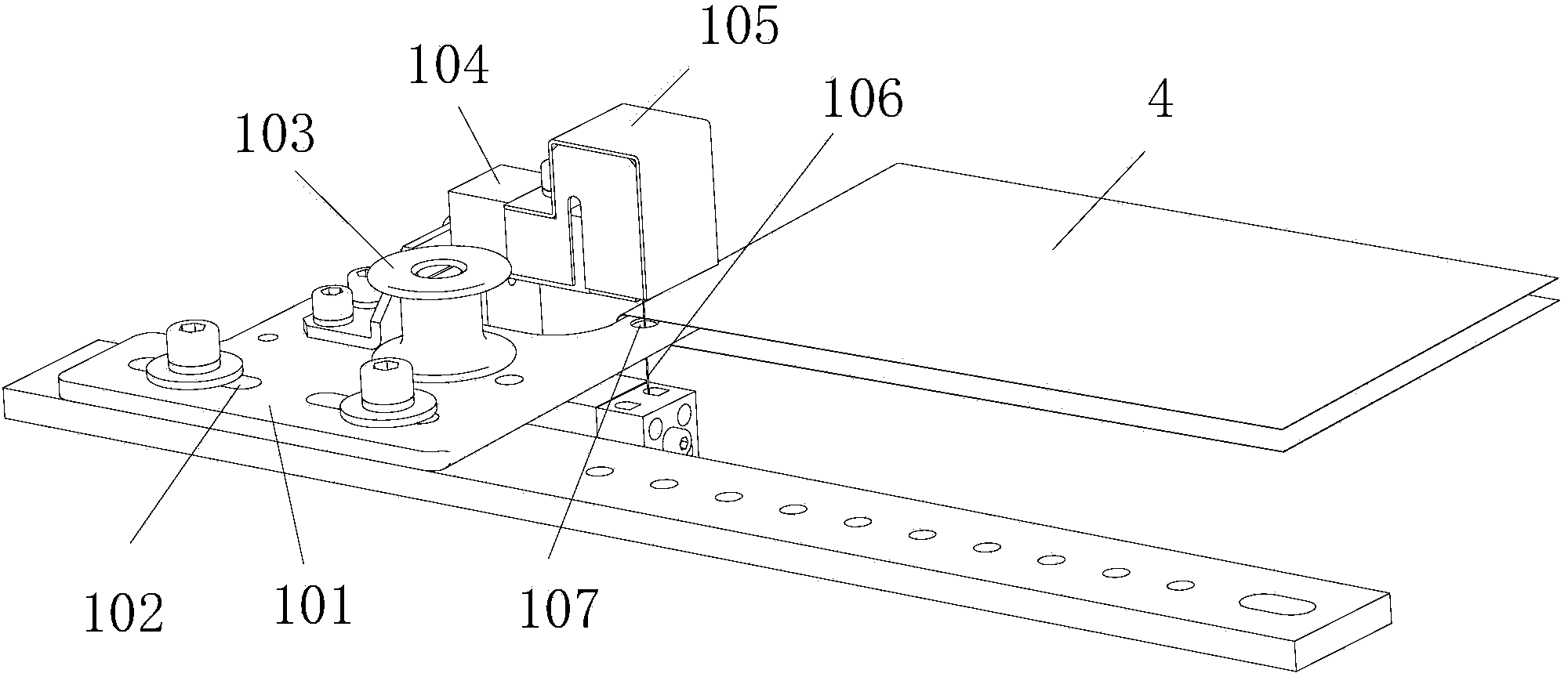

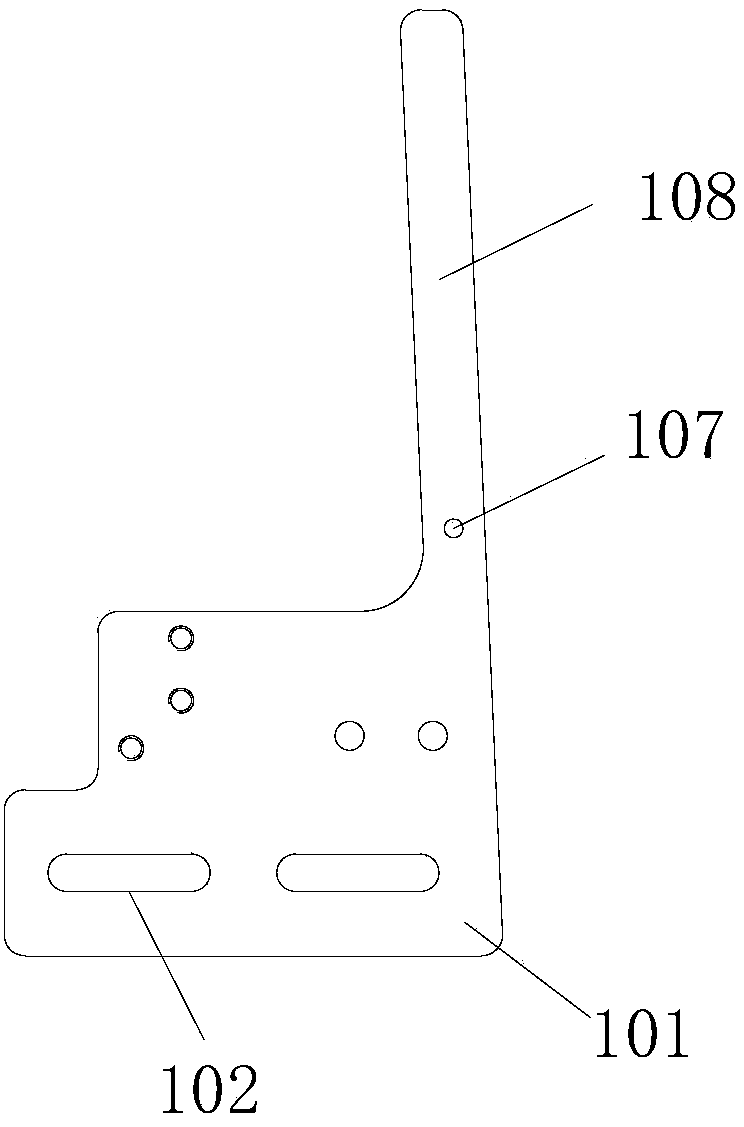

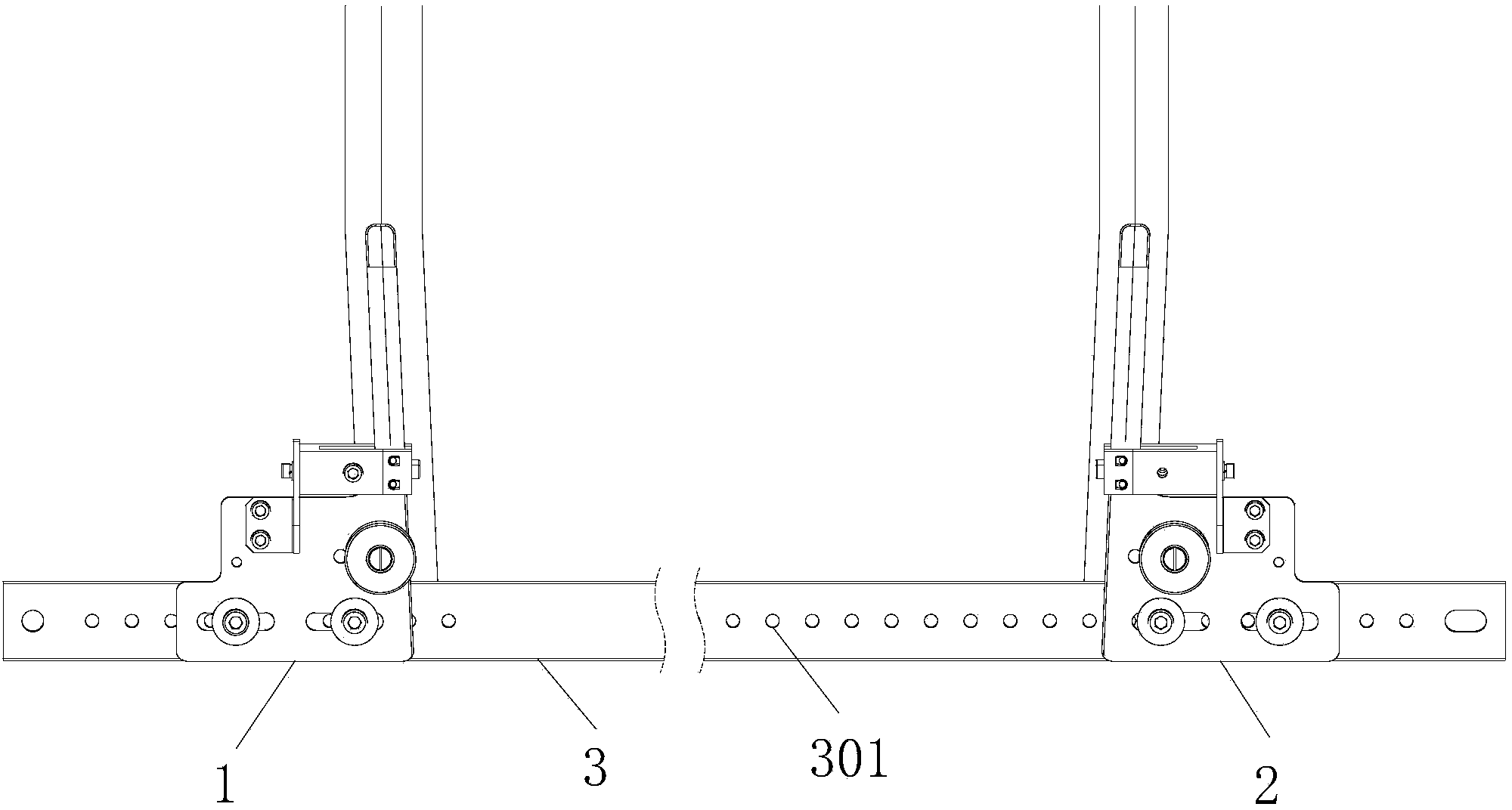

[0020] Such as Figure 1 to Figure 3 As shown, a flannelette air-jet loom side stand ironing device includes a left support 1, a right support 2 and a fixing plate 3 for positioning the left and right supports. The fixing plate 3 is installed on the left and right sides of the air-jet loom frame. On the wallboard, the structures of the left and right braces are the same, both of which include a temple body 101, a plurality of positioning holes 301 are evenly distributed on the fixing plate 3, and two positioning grooves 102 are arranged side by side at the bottom of the temple body 101, each The positioning groove 102 faces at least three positioning holes 301. When the width of the weaving cloth changes, the positions of the left and right support can be adjusted at any t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com