Method for simulating standard suction of smoking machine by stepping motor

A stepper motor, smoking machine technology, used in the testing of machine/structural components, measuring devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

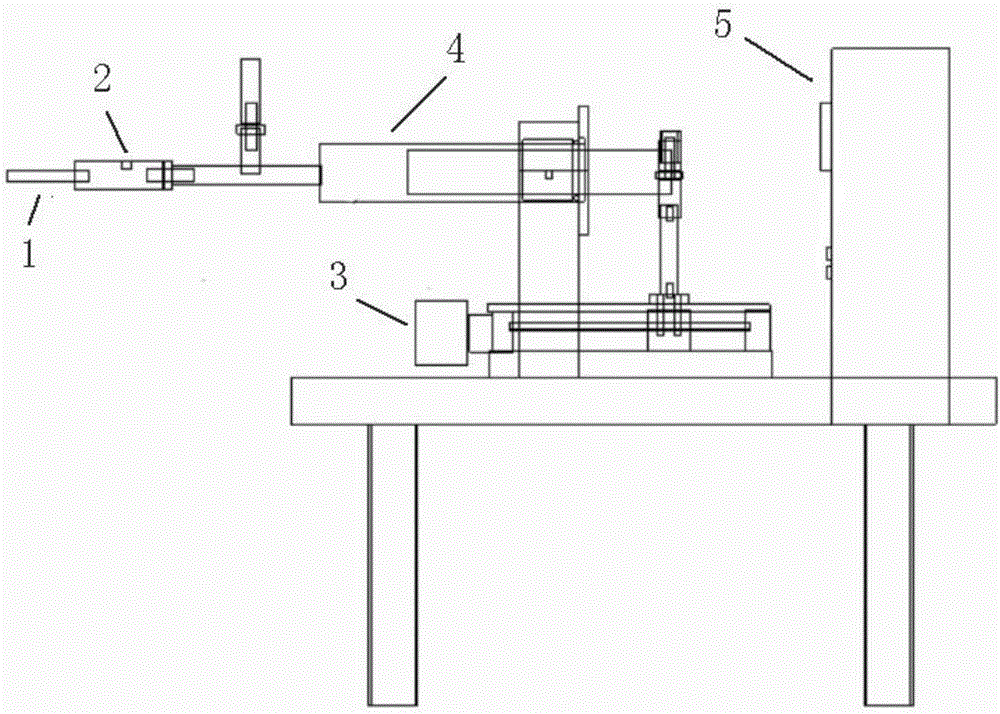

[0041] Such as figure 1 As shown, it is a schematic diagram of the experiment of measuring the outlet pressure of the cigarette and the stepping motor simulating the standard smoking of the smoking machine in this embodiment, including: cigarette 1, pressure gauge contact probe socket 2, stepping motor 3, suction device 4, control Box 5.

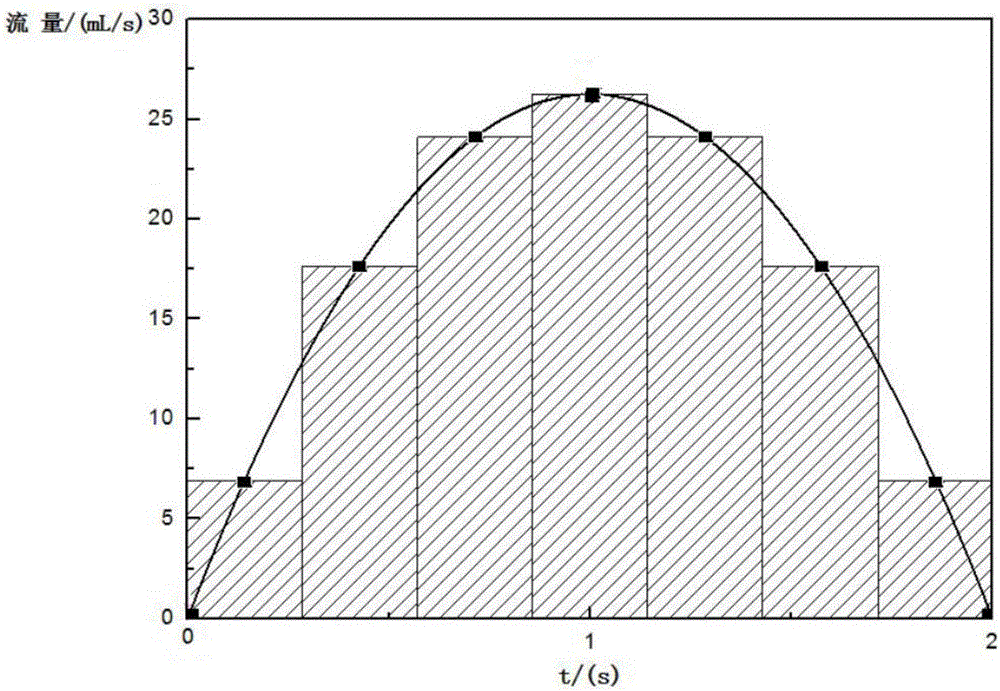

[0042] Based on the above experimental schematic diagram, as figure 2 As shown, the method for the stepping motor of the present embodiment to simulate the standard smoking of the smoking machine includes the following steps:

[0043] (1) Approximate the bell-shaped flow diagram of the standard suction of the smoking machine as a parabola Q=At 2 +Bt, and divide the parabola into 7 time equal parts according to the abscissa, and the median time of each part is t1 , t 2 ,...,t 7 , and find its corresponding flow value Q 1 , Q 2 ,...,Q 7 ;

[0044] Approximate the bell-shaped flow diagram of the standard suction of the smoking machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com