Preparation system and method of vanadium slag pellets

A preparation system and technology for vanadium slag, applied in the field of metallurgy, can solve the problems of reducing the slag pelletizing rate, the probability of vanadium slag contacting moisture is different, and the spheroidizing rate is only small, so as to be suitable for large-scale production, and the production environment is friendly. , the effect of uniform particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

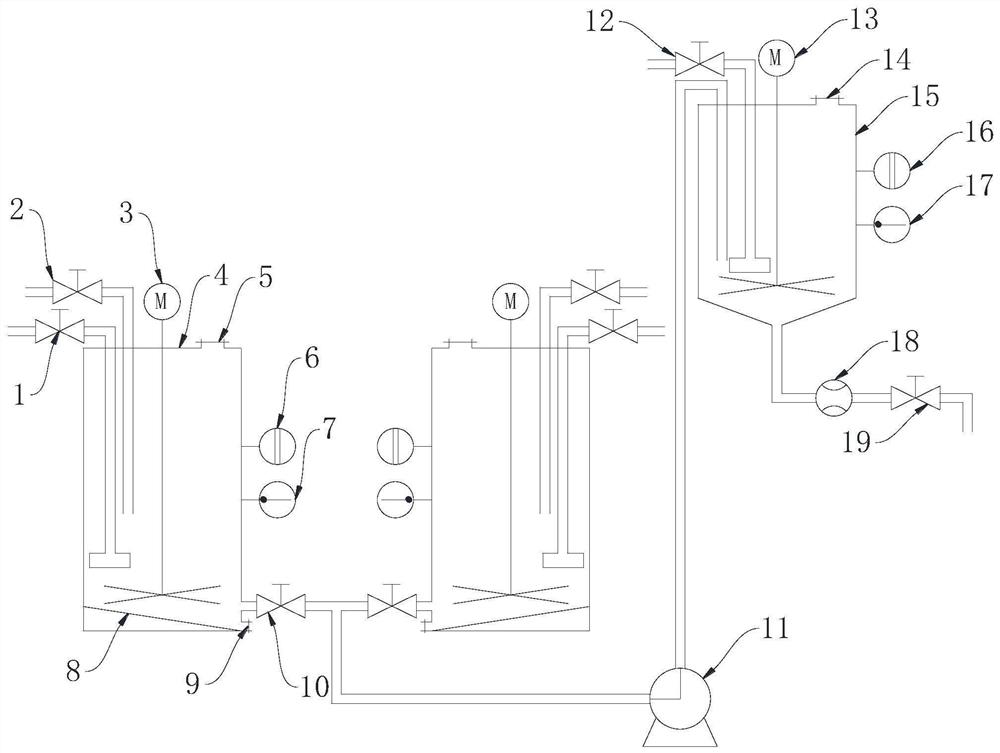

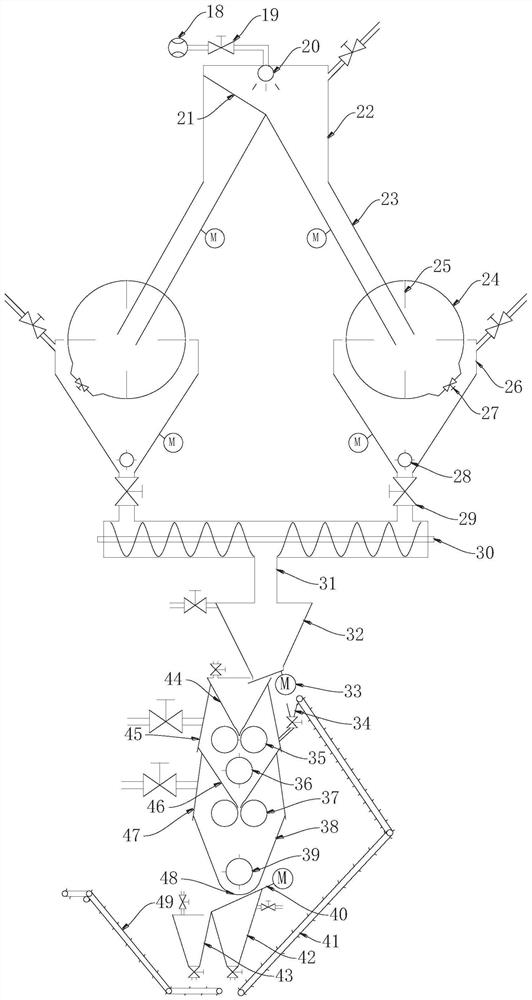

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

[0040] The briquetting device can be selected as the vanadium slag granulation device disclosed by CN 109999721 A.

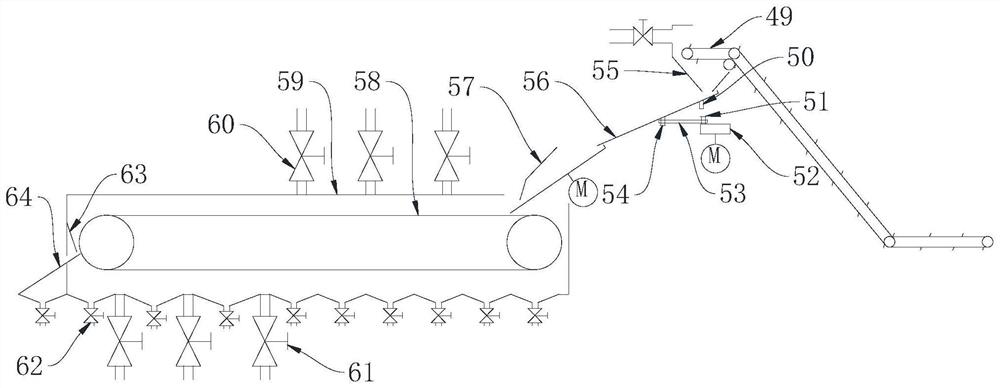

[0041] The cloth device and the drying device are shown in FIG. 2 . The discharge end of the second inclined belt 49 is located at the top of the second buffer bin 55,

[0047] The vanadium slag pellet preparation method is supplemented below.

[0048] S1. Preparation of the binder. The binder is prepared according to the mass ratio of humic acid: flake alkali: water = 3:1:17.

[0049] S2. Prepare the mix. Soda ash and vanadium slag in the initial mixture are based on the molar ratio of sodium element of soda ash to vanadium element in vanadium slag

[0050] The hopper 22 is a rectangular box with a length of 300mm, a width of 200mm and a height of 400mm. The movable flap 21 is a square with a side length of 300mm

[0052] S4. Cloth. Buffer bin two 55 vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com