Valve assembly for an injection valve and injection valve

A technology of valve components and injection valves, which is applied in the direction of fuel injection devices, special fuel injection devices, engine components, etc., and can solve problems such as reducing valve needle guide length, wear, and functional problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

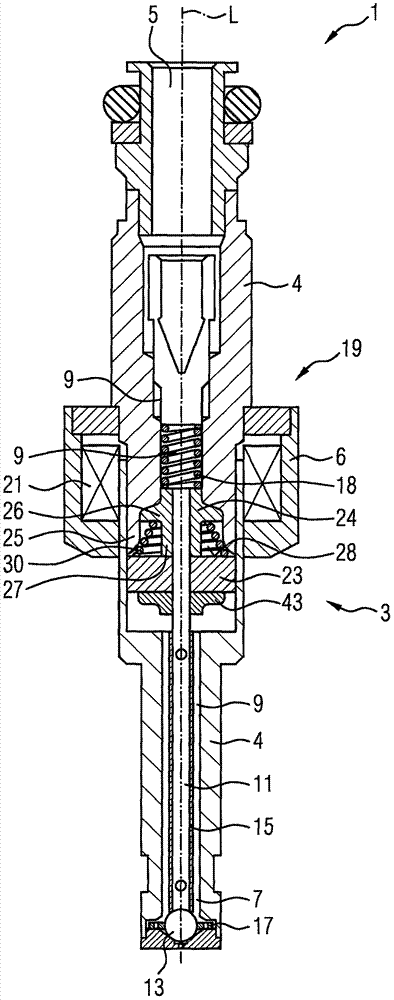

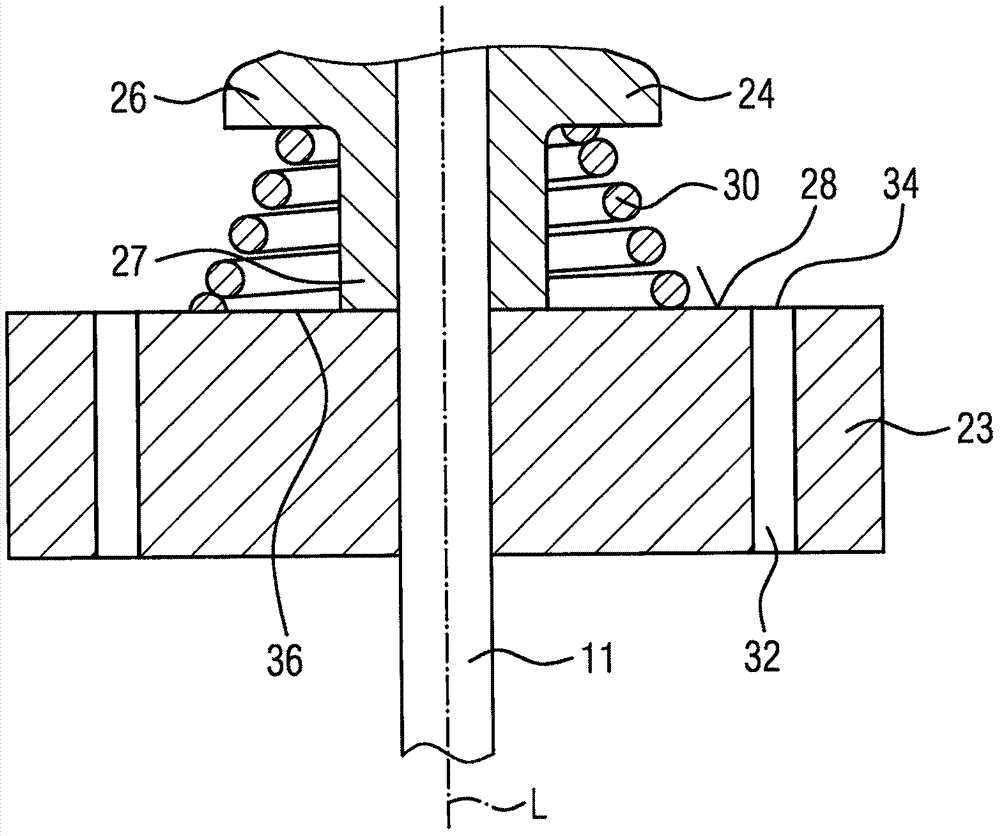

[0028] figure 1 Shown is an injection valve 1 which is particularly suitable for supplying fuel to an internal combustion engine. Injection valve 1 comprises in particular a valve assembly 3 . Said valve assembly 3 comprises a valve body 4 having a central longitudinal axis L. As shown in FIG. The housing 6 is partially disposed around the valve body 4 .

[0029] The valve body 4 includes a cavity 9 . The cavity 9 has a fluid outlet portion 7 . The fluid outlet portion 7 communicates with the fluid inlet portion 5 provided in the valve body 4 . The fluid inlet portion 5 and the fluid outlet portion 7 are in particular located at opposite axial ends of the valve body 4 . The cavity 9 receives the valve needle 11 . The valve needle 11 includes a needle shaft 15 and a sealing ball 13 welded to the tip of the needle shaft 15 .

[0030] In the closed position of the valve needle 11 it rests sealingly against a seat plate 17 with at least one injection nozzle. A preloaded ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com