Pneumatic tire

A technology for pneumatic tires and tires, applied in tire parts, tire treads/tread patterns, transportation and packaging, etc. problem, to achieve the effect of improving partial wear resistance and inhibiting soil dumping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

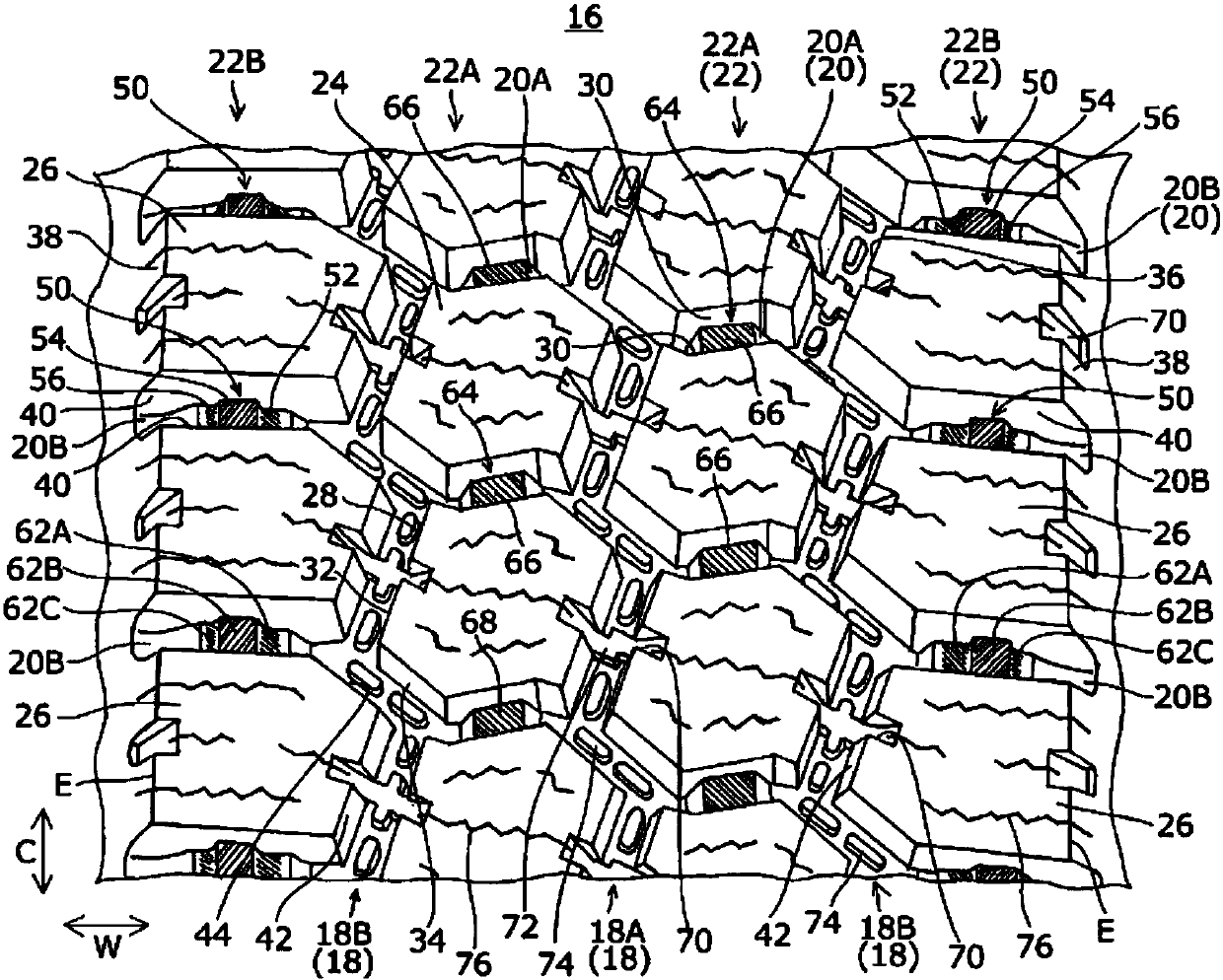

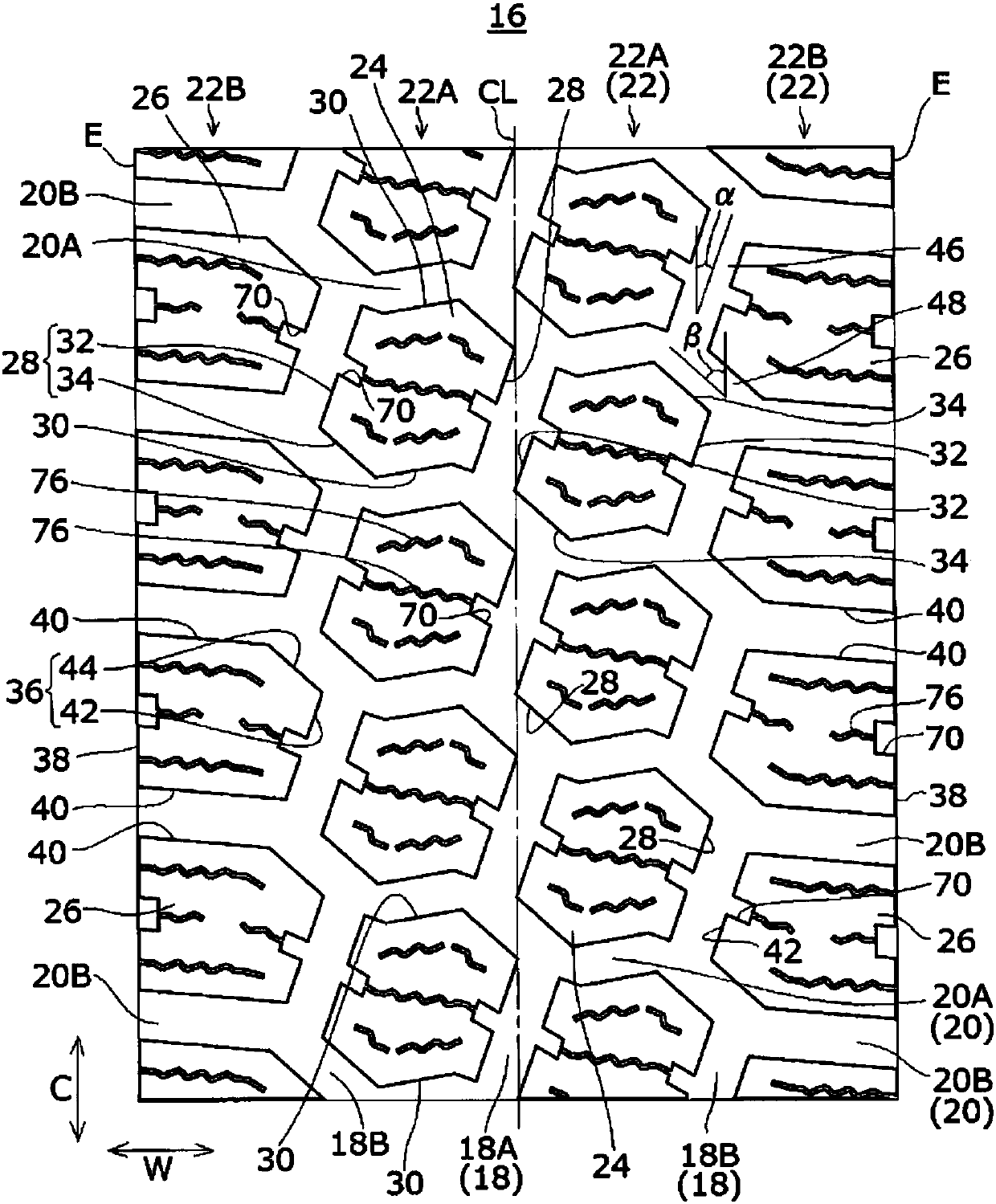

[0062] The tire of Example 2 has Figure 1-7 Features of the embodiment shown in . In embodiment 2, set the groove width of main groove=11.5mm, the depth of main groove=16.5mm, for the first~the 3rd shallow groove part 52,54,56 (expressed as " three grades " in table 1 ), set H1=H3=9.9mm, H2=7.9mm, L1=8.5mm, L2=8.0mm, L3=4.5mm, L0=35.2mm, G=1.0mm, D=0.6mm, make the second shallow The center position M1 of the groove portion is shifted by 2.0 mm toward the tire contact edge E side with respect to the center position M0 of the lateral groove. In the tire of Example 1, the center position M1 of the second shallow groove coincides with the center position M0 of the lateral groove, and has the same structure as that of the tire of Example 2 in other respects. In the tire of Comparative Example 1, the first to third shallow grooves 52 , 54 , and 56 are not provided in the transverse groove 20B between the shoulder blocks 26 , but instead, one stage with a depth of 8.9 mm and a len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com