Vehicle ash water recycling and reusing device

A technology for recycling and gray water, applied in water/sewage treatment, water/sludge/sewage treatment, transportation and packaging, etc., can solve problems such as gray water overflow, no treatment, reuse, and failure to meet environmental protection requirements , to save energy and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

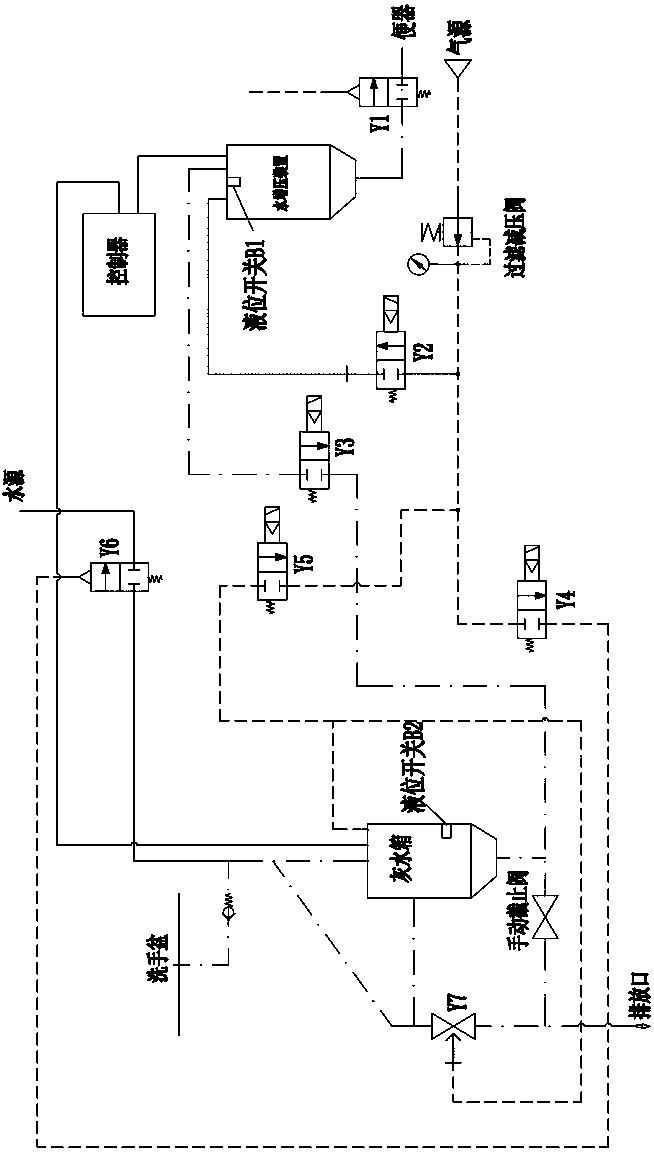

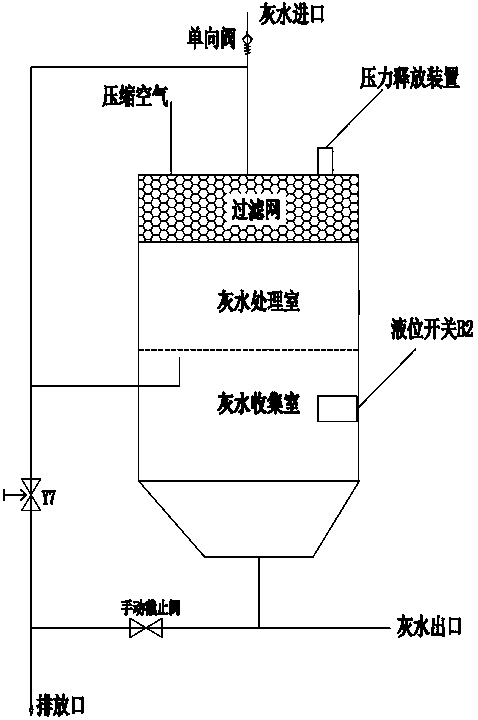

[0016] Such as figure 1 , figure 2 As shown, the vehicle gray water recovery, treatment and reuse device includes the vehicle gray water recovery, treatment and reuse device, which includes a gray water unit, a flushing unit, and a controller.

[0017] The gray water unit includes a gray water tank main body, a one-way valve, an air-controlled two-way valve Y6, an air-controlled booster solenoid valve Y5, and an air-controlled overflow valve. The gray water inlet, fresh water source inlet, gas inlet and Pressure release device, the gas inlet is connected to the gas source through the air-controlled booster solenoid valve Y5, the gray water inlet is connected to the vehicle washbasin after a one-way valve is set, the fresh water inlet is connected to the water source through the air-controlled two-way valve Y6, and the air-controlled The two-way valve Y6 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com