Improved cold chain box

An improved, cold chain technology, applied in the types of packaging items, household refrigeration devices, containers, etc., can solve the problems of low use efficiency of cold storage agent, waste of cold storage agent, fixed internal storage space, etc., to improve the use efficiency, Guaranteed thermal insulation effect, reducing the effect of cooling air loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

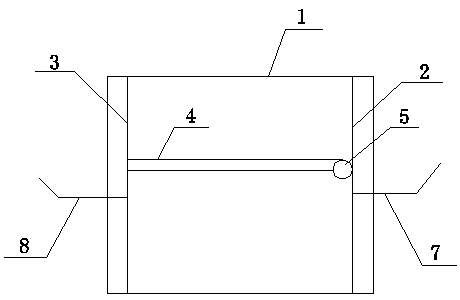

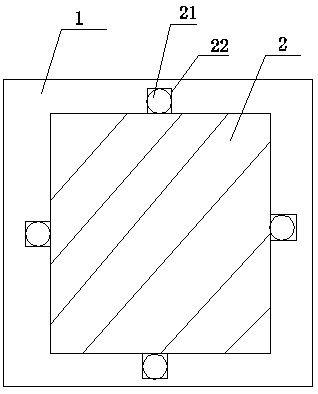

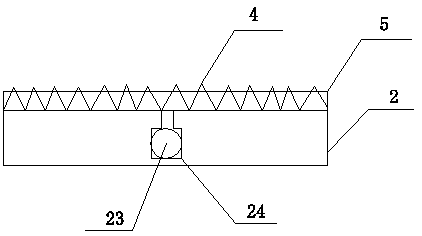

[0019] like Figure 1 to Figure 5 As shown, the present invention provides an improved cold chain box, which includes a box body 1, and the two ends of the box body 1 are respectively provided with a first heat-insulating partition plate 2 and The second heat-insulating partition board 3, the opposite surfaces of the first heat-insulating partition board 2 and the second heat-insulating partition board 3 are respectively fixedly connected to push the first heat-insulating partition board 2 and the second heat-insulating partition board. The first threaded adjustment rod 7 and the second threaded adjustment rod 8 that the partition plate 3 moves in the box body 1, the first threaded adjustment rod 7 and the second threaded adjustment rod 8 are respectively threaded with the two ends of the box body 1 and Extending outwards, the first heat-insulating partition board 2 and the second heat-insulating partition board 3 are provided with a distribution shaft 5 on the opposite surfac...

Embodiment 2

[0021] Put the object in the box 1, turn the first threaded adjustment rod 7 and the second threaded adjustment rod 8 respectively to adjust the positions of the first heat-insulating partition plate 2 and the second heat-insulated partition plate 3 to be able to squeeze against the object, Then pull out the fixed bayonet 6, adjust the height of the cloth release shaft 5, so that the glass fiber insulation cloth 4 can be close to the object after being pulled out, then insert the fixed bayonet 6 into the roller groove 24 again, and put the cloth The position of the shaft 5 is fixed, and the glass fiber heat-insulating cloth 4 is pulled to the second heat-insulating partition plate 3, and the limit bayonet 41 is inserted and snapped into the bayonet groove 31, so that the formed storage area is not only large enough to It is suitable for the object, and the stability of the object in the storage area is high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com