Anti-backflow air exhaust pipe of lampblack flue

An anti-backflow and exhaust pipe technology, applied in the field of exhaust pipes, can solve the problems affecting the exhaust and stop functions of the exhaust pipes of range hoods, complex operating conditions of public flues, and weak closing and anti-reverse performance. To achieve the effects of alleviating oil fume backflow, solving oil fume backflow prevention, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in further detail below in conjunction with accompanying drawing:

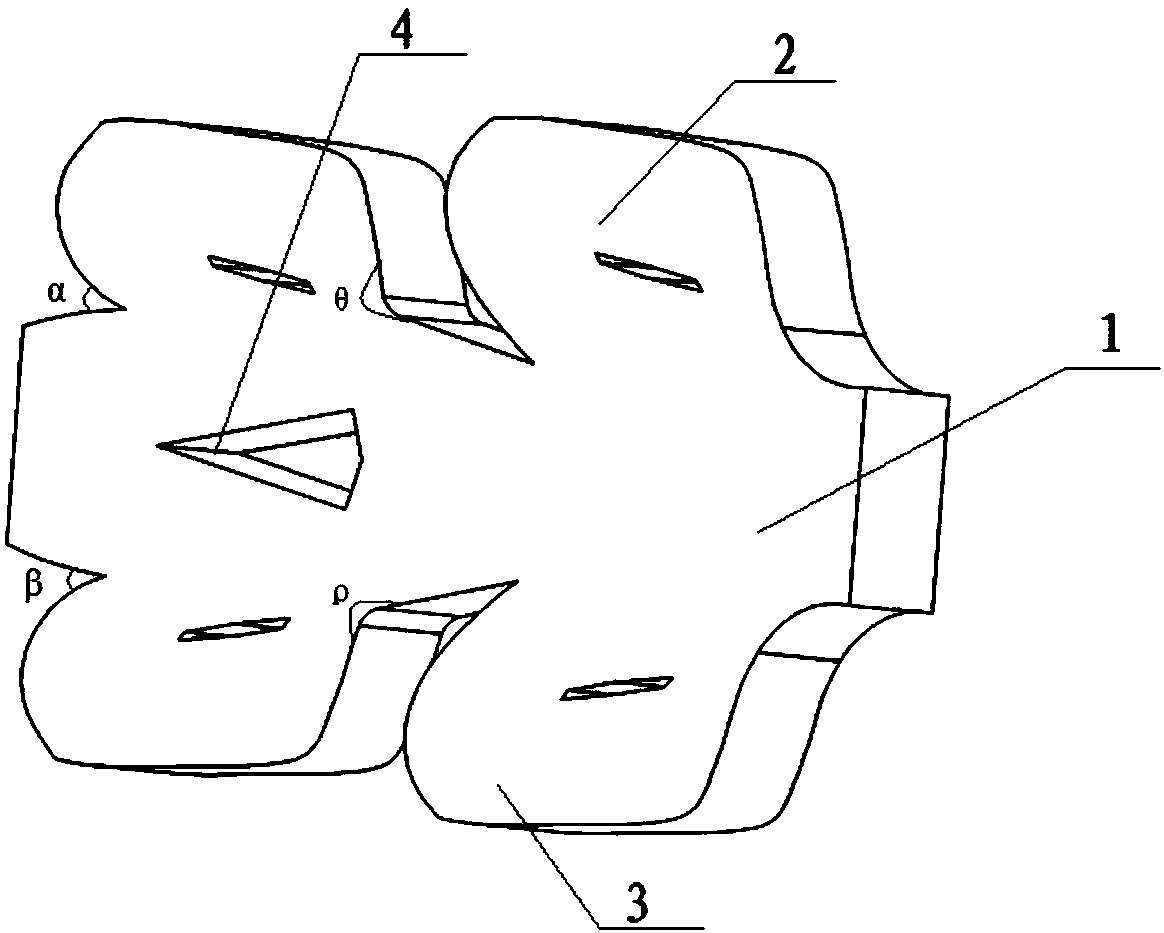

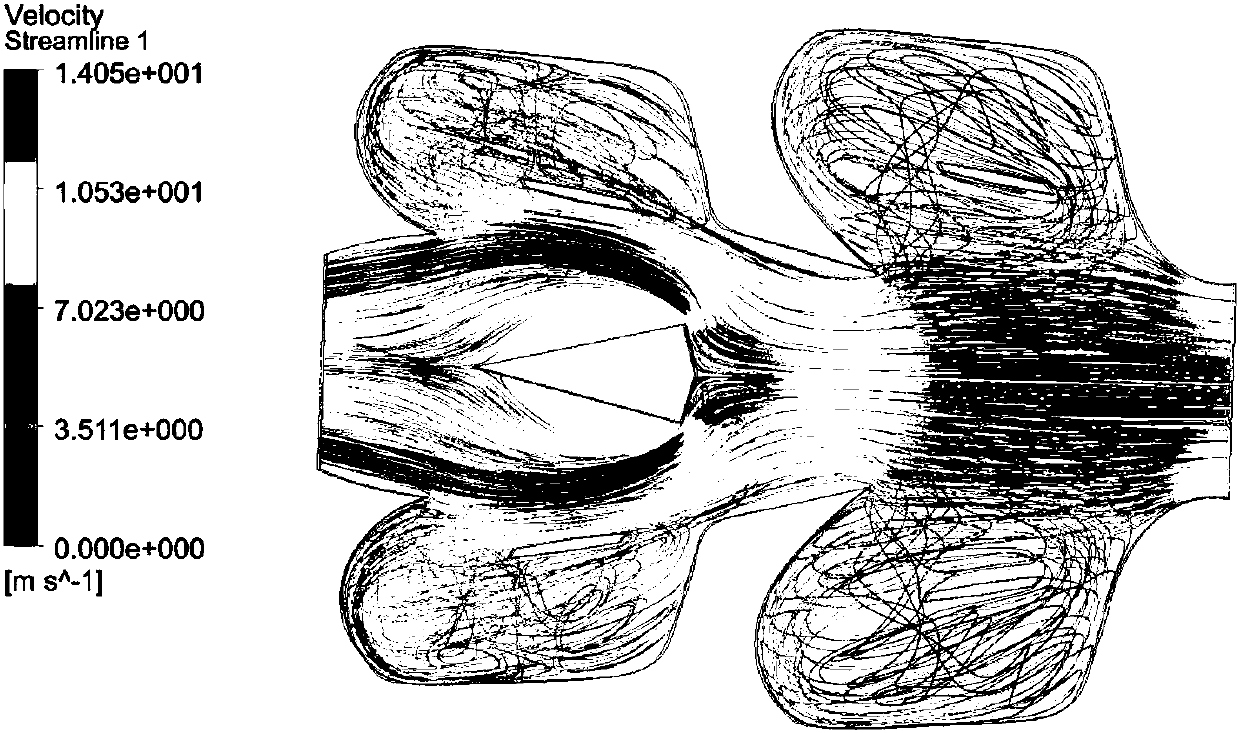

[0020] refer to figure 1 , the anti-backflow air duct of the oil fume duct according to the present invention includes a main channel 1, a plurality of first auxiliary channels 2 and a plurality of second auxiliary channels 3, each of the first auxiliary channels 2 and each of the second auxiliary channels 3 are circular The left end of the main channel 1 is provided with a soot inlet, the right end of the main channel 1 is provided with a soot outlet, and the side of the main channel 1 is provided with a number of soot ports, wherein one soot port corresponds to a first auxiliary channel 2 or a first auxiliary channel 2. Two auxiliary passages 3, each first auxiliary passage 2 and each second auxiliary passage 3 communicate with the corresponding lampblack port on the main passage 1; the position where each first auxiliary passage 2 communicates with the main passage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com