Multi-scale structural material integrated design method based on shape features

A technology of structural materials and design methods, applied in computing, special data processing applications, instruments, etc., can solve problems such as poor practicability, and achieve the effect of good practicability and increased calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

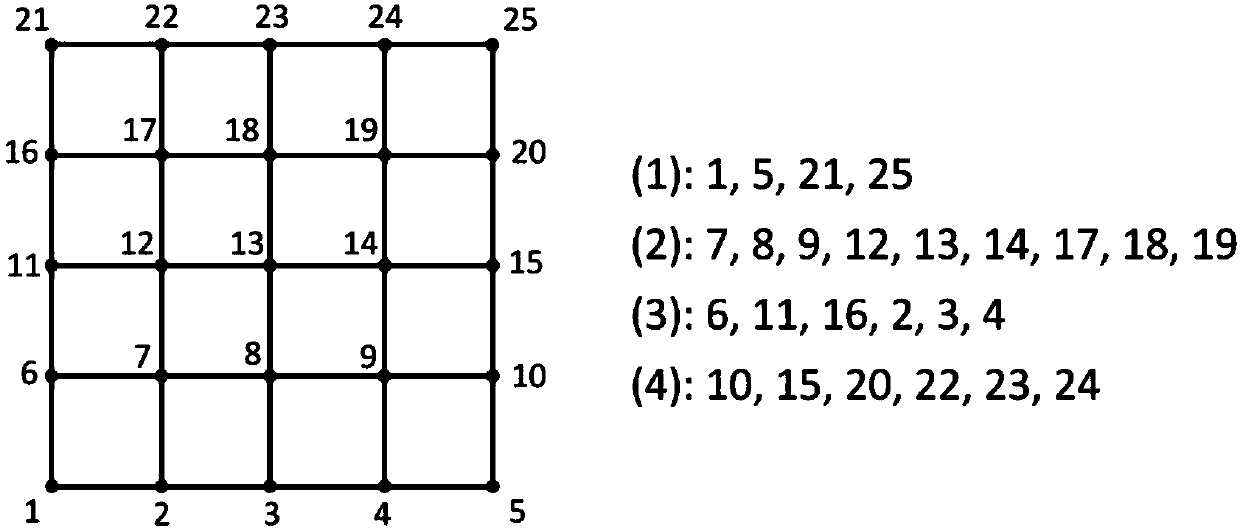

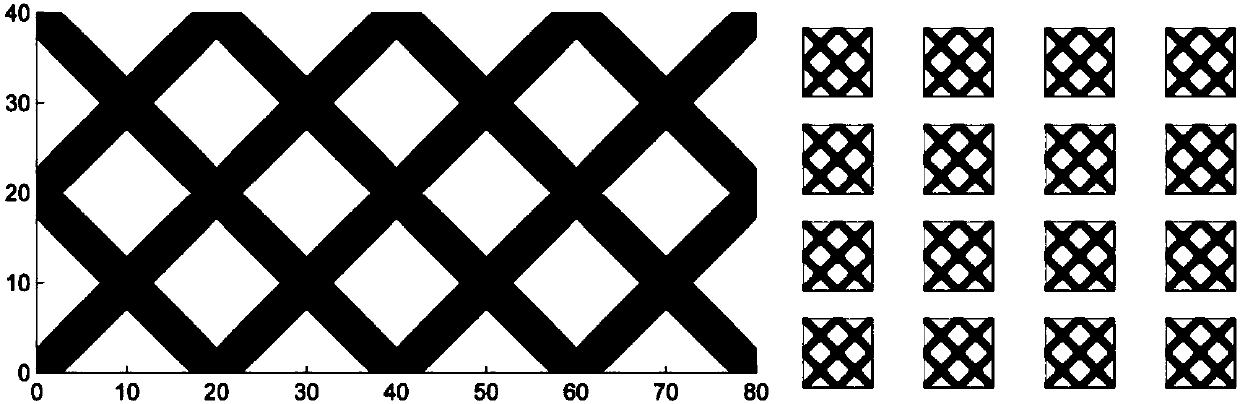

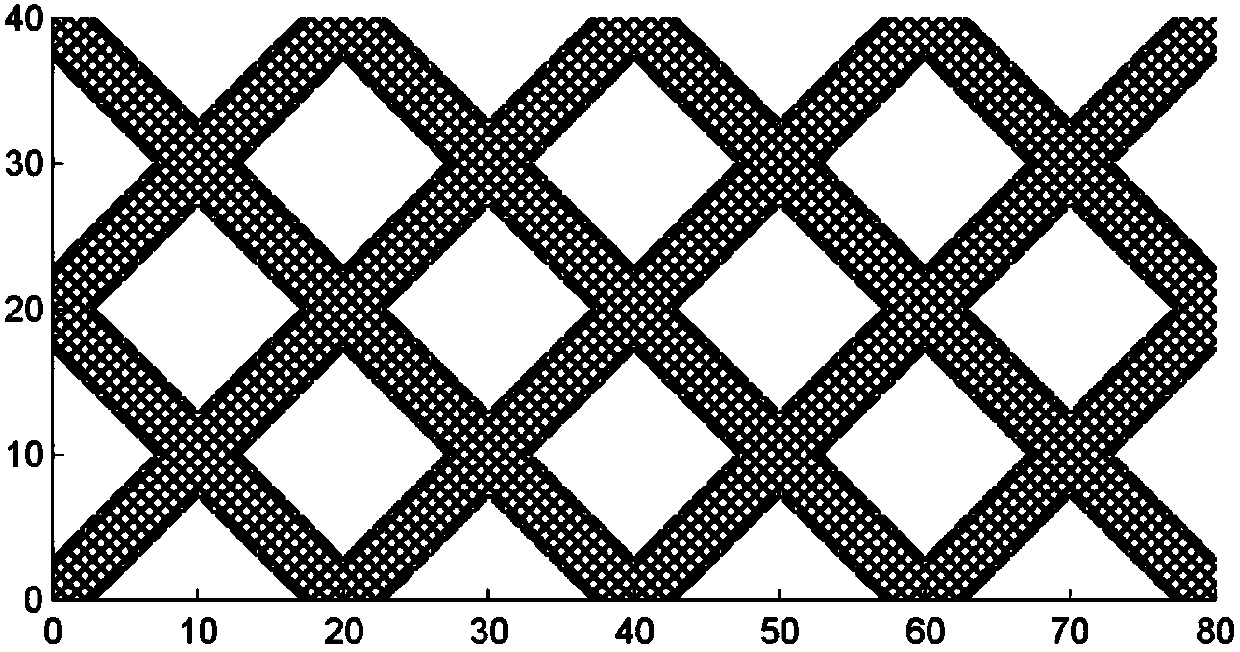

[0037] refer to Figure 1-5 . The multi-scale structural and material integrated design method based on shape features of the present invention is used for structural and material integrated design, considering that the size of the structural design area is 80×40mm, the left side of the area is fixed, and the lower right corner receives a downward concentrated force F=100N. The Young's modulus and Poisson's ratio of the structural material are E=10Pa, ν=0.3, respectively. Specific steps are as follows:

[0038] Step 1. Refer to figure 2 on the right. The number of microstructural configuration units is determined to be 16, the size of each microstructural unit cell is 50×50, and the number of microstructural features contained in each unit cell is 8, and its basic parameters are

[0039] Table 1

[0040]

[0041] Then calculate the level set function φ of the overall microstructure according to formula (1).

[0042]

[0043] φ=max(φ i )

[0044] Step 2. Calculate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com