A method of batik painting and re-dyeing using prefabricated silk screen plates

A technology of plate and silk screen, applied in the field of batik painting, can solve problems such as the emergence of ills in works and the confusion of authors, and achieve the effect of simple painting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A kind of method that adopts prefabricated screen plate to carry out batik painting, promptly utilizes the present invention to carry out overall painting, and its concrete steps are as follows:

[0051] Step 1: Spread and rub wax on drawing paper or fabric with micropores;

[0052] Step 2: Place the drawing paper or fabric treated in step 1 on another drawing paper;

[0053] Step 3: Carry out dyeing and painting;

[0054] Step 4: Stand still, the pigment or dye penetrates into another drawing paper through the micropores, remove the drawing paper or fabric with the micropores, observe the picture presented on the drawing paper below, choose according to the need, observe the picture is complete, start step 5;

[0055] Step 5: Rinse with cold water to remove pigments or dyes on the microporous drawing paper or fabric, prefabricate it into a whole screen plate, and store it for later use;

[0056] Step 6: When it is necessary to dye the batik picture, select the prefabr...

Embodiment 2

[0063] A kind of method that adopts prefabricated screen plate to carry out batik painting, promptly utilizes the present invention to carry out overall painting, and its concrete steps are as follows:

[0064] Step 1: Spread and rub wax on drawing paper or fabric with micropores;

[0065] Step 2: Place the drawing paper or fabric treated in step 1 on another drawing paper;

[0066] Step 3: Carry out dyeing and painting;

[0067] Step 4: Stand still, the pigment or dye penetrates into another drawing paper through the micropores, remove the drawing paper or fabric with the micropores, observe the picture presented on the drawing paper below, choose according to the need, and observe whether the picture is complete or not Satisfactory results have been shown, start step 5;

[0068] Step 5: Rinse with cold water to remove pigments or dyes on the microporous drawing paper or fabric, prefabricate it into a whole screen plate, and store it for later use;

[0069] Step 6: When it...

Embodiment 3

[0077] A kind of method that adopts prefabricated screen plate to carry out batik dyeing, its specific steps are as follows:

[0078] Step 1: Spread and rub wax on drawing paper or fabric with micropores;

[0079] Step 2: Place the drawing paper or fabric treated in step 1 on another drawing paper;

[0080] Step 3: Carry out dyeing and painting;

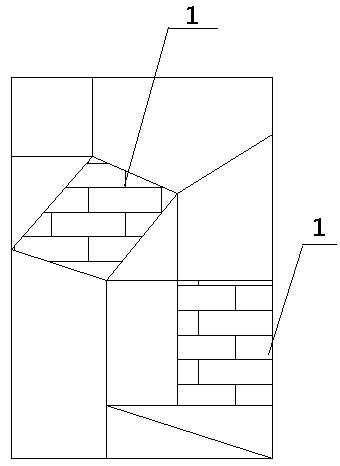

[0081] Step 4: Stand still, the pigment or dye penetrates to another drawing paper through the micropores, remove the drawing paper or fabric with the micropores, observe the picture presented on the drawing paper below, and replace the drawing paper with the micropores as needed Drawing paper or fabric is divided into various parts ( figure 1 shown);

[0082] Step 5: Divide it, take its part (part 1 selected in the step), remove the pigment or dye on it, pre-fabricate several screen plates, and store them for later use;

[0083] Step 6: When the batik picture needs to be re-dyeed, select the matching silk screen plate prefabrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com