Horizontal base positioning and adjusting tooling and adjusting method thereof

A positioning adjustment and base technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., to reduce the scope of manual adjustment, reduce the number of manual adjustments, and save manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

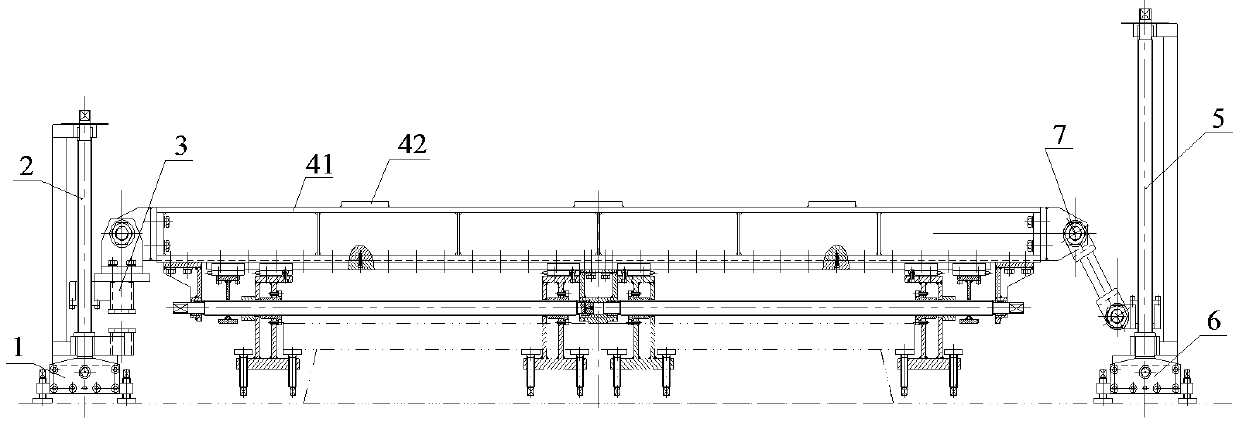

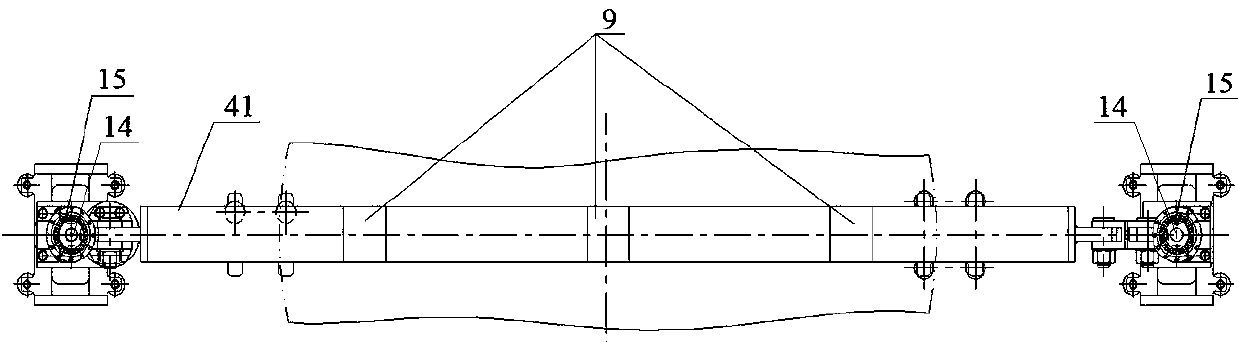

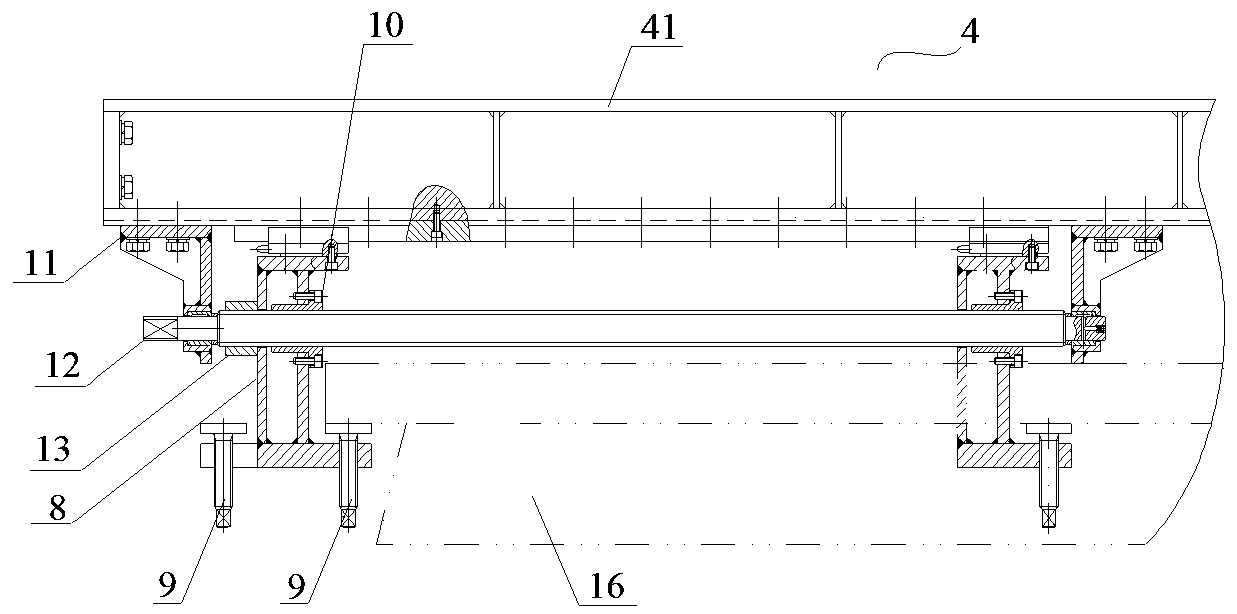

[0030] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the horizontal base positioning adjustment tool of this embodiment includes a first midship adjustment mechanism 1, a first lifting mechanism 2, a rotating mechanism 3, a clamping mechanism 4, a second lifting mechanism 5, and a second midship adjustment mechanism. Adjusting mechanism 6 and linkage mechanism 7, the first midship adjusting mechanism 1 is fixed on the lower end of the first lifting mechanism 2, one end of the clamping mechanism 4 is connected with the first lifting mechanism 2 through the rotating mechanism 3, and the clamping mechanism The other end of 4 is connected with the second lifting mechanism 5 through the linkage mechanism 7, and the lower end of the second lifting mechanism 5 is fixedly connected with the second midship adjustment mechanism 6.

[0031] The clamping mechanism 4 of this embodiment includes a crossbeam 41 and a base fixing mechanism, a horizontal detection platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com