Automatic leveling method for large-aperture planar optical element

An optical element and automatic leveling technology, applied in the field of optics, can solve problems such as difficult to find feature points, less distribution of feature points, increased time, etc., to solve the problem of defocus, simple leveling method, and improve leveling speed and accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings. It should be noted that the following embodiments are intended to facilitate the understanding of the present invention, but do not limit it in any way.

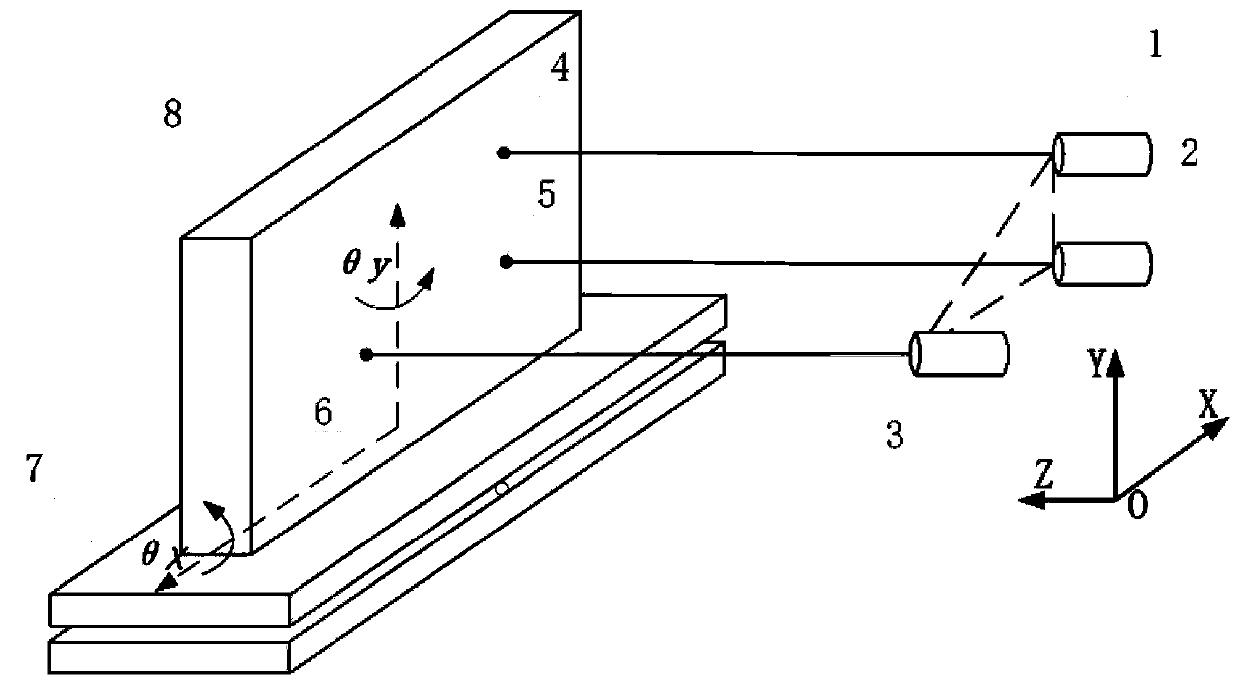

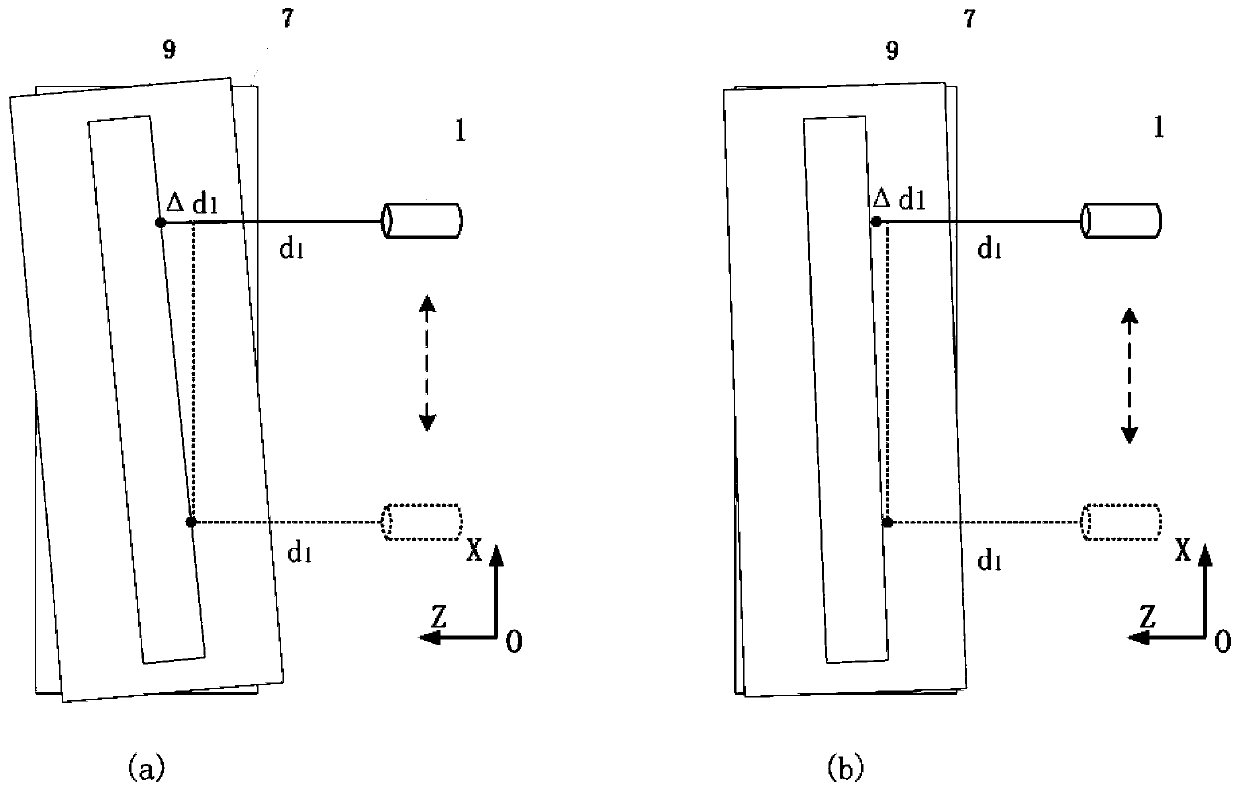

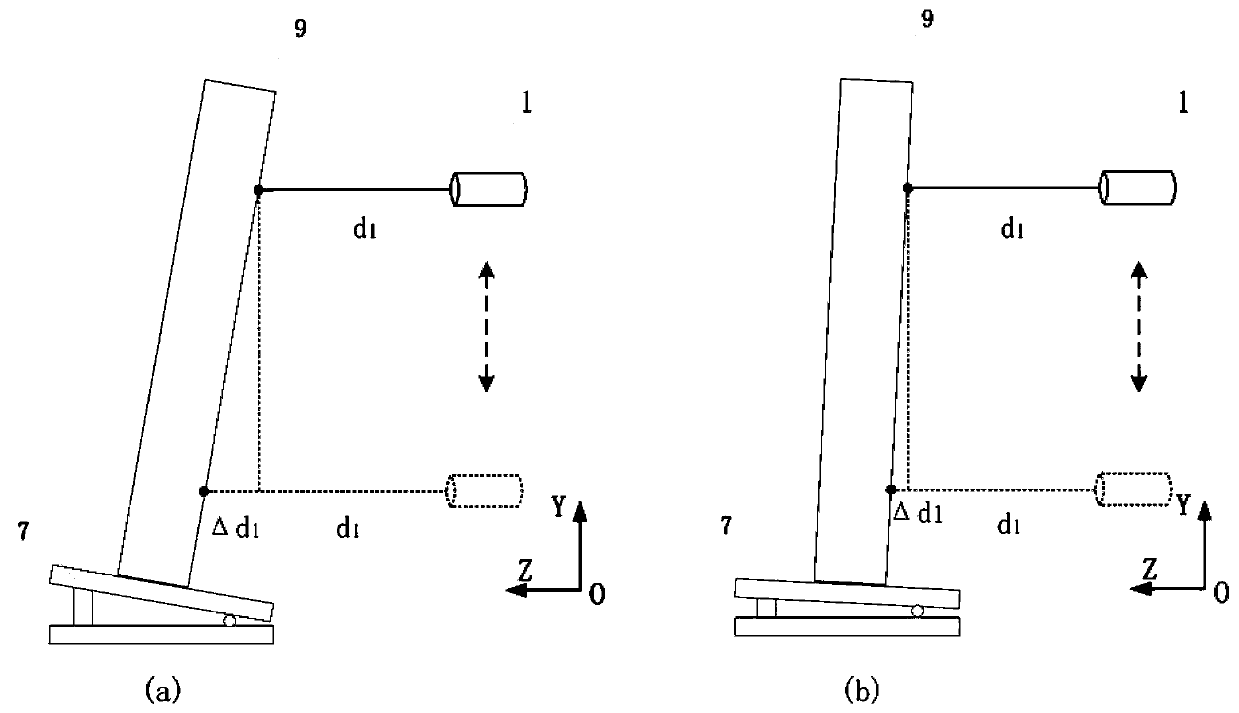

[0041] automatic leveling device such as figure 1shown. The large-diameter planar optical element 8 to be leveled is fixed on the sample stage adjustment platform 7 in a vertical position, and the surface of the element is perpendicular to the horizontal plane. The sample adjustment platform 7 can carry the sample to adjust two angles of pitch θx and rotation θy. The three laser displacement sensors are: a first laser displacement sensor 1 , a second laser displacement sensor 2 , and a third laser displacement sensor 3 . Three laser displacement sensors are fixed on the three-dimensional translation platform. The X and Y axes of the three-dimensional translation platform are parallel to the surface of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com