Vacuum ink injection machine

An ink filling and vacuum technology, applied in printing, printing devices, etc., can solve the problems of lower printing quality, waste, and unenvironmental protection of ink cartridges, and achieve the effects of increasing the number of refilling, reducing the content of air bubbles, and accurately filling the amount of ink.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

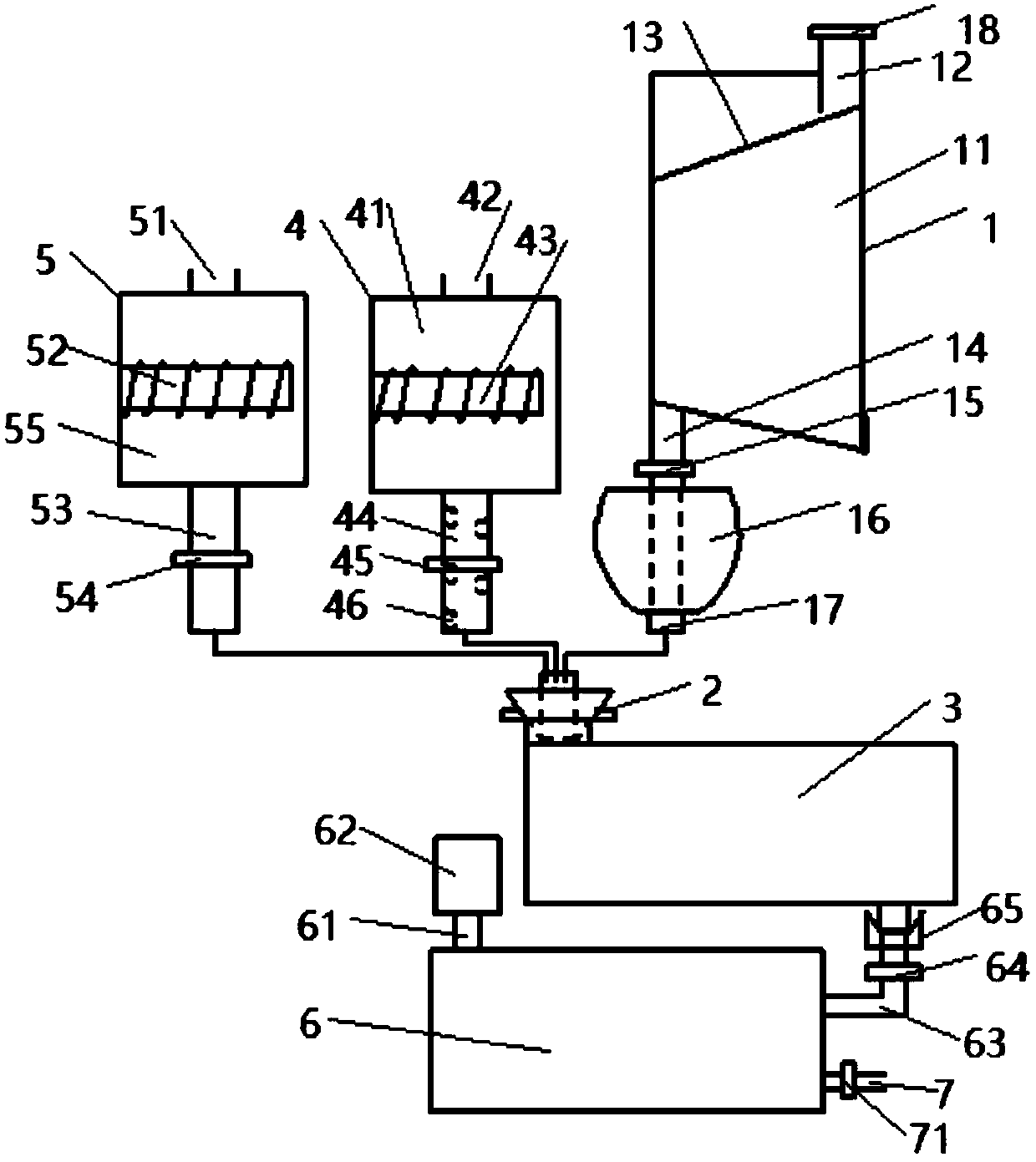

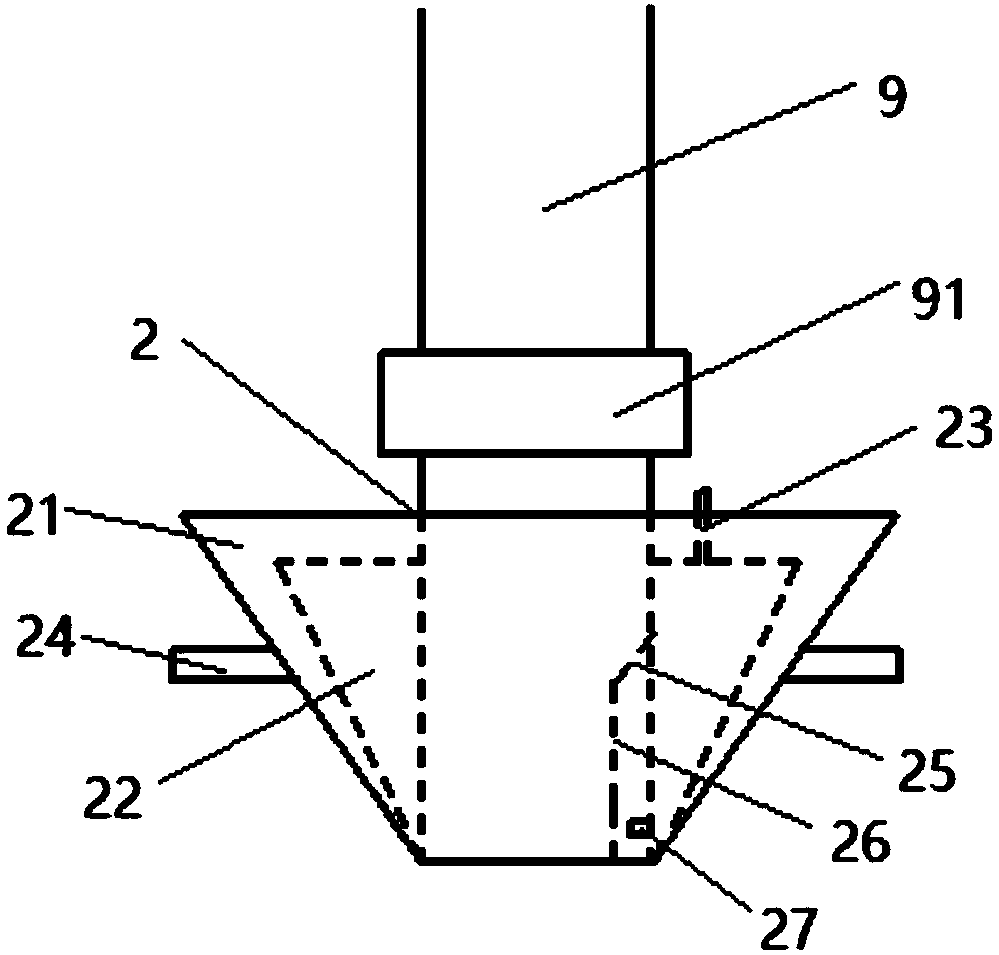

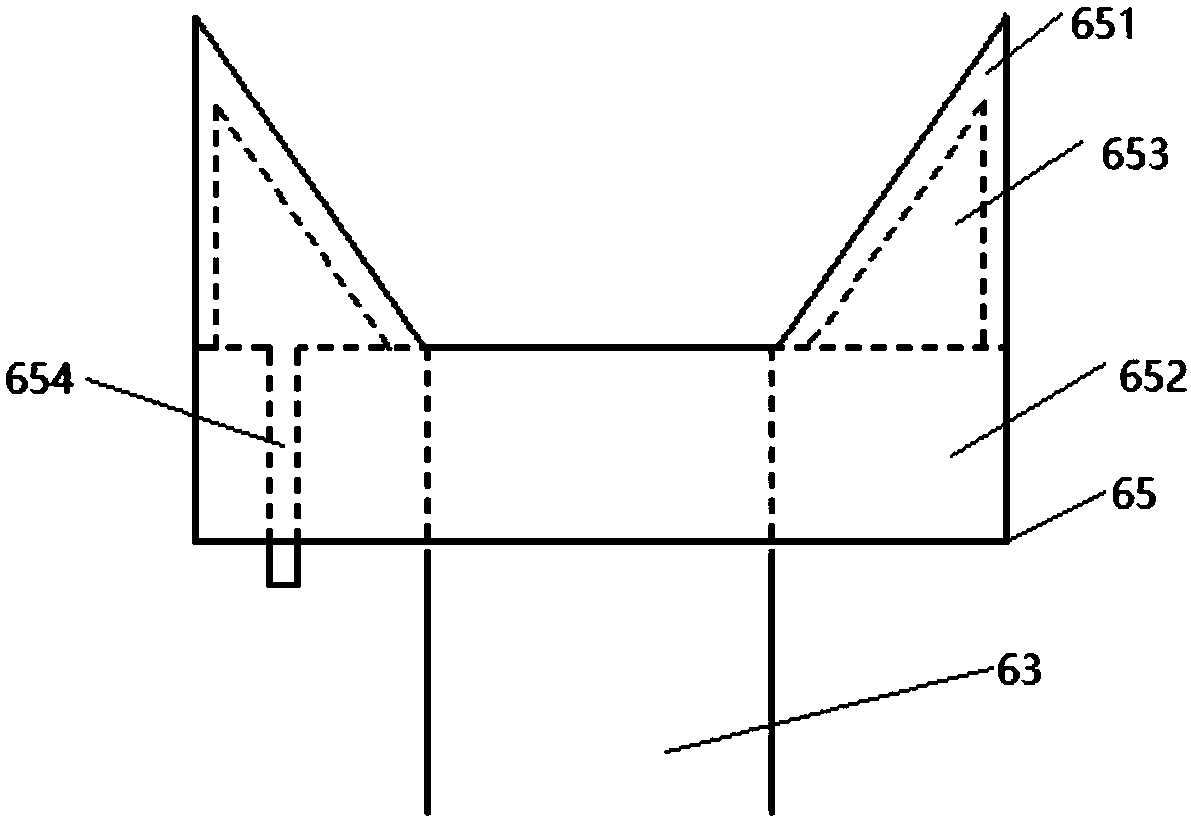

[0038] Such as Figure 1-6 As shown, the present invention provides a vacuum ink filling machine, comprising:

[0039] Housing 8, which is a hollow cuboid, the middle part of one side is inwardly recessed to form an ink cartridge accommodation area;

[0040] A plurality of ink storage devices 1, which are arranged above the accommodating area 81 inside the housing 8, any ink storage device 1, which includes:

[0041] Ink cartridge 11, which is a hollow cuboid structure, is provided with an ink filling port on its top, and a flow deflector 13 that is inclined downwards is provided below the described ink filling port 12, and the upper end of the flow deflector 13 is in contact with the ink cartridge. The inner wall of the cartridge 11 is fixedly connected, and the lower end abuts against the inner wall of the ink cartridge 11. The two sides of the deflector 13 are set so as not to contact the inner wall of the ink cartridge 11, and the two sides of the deflector 13 A baffle 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com