Graphite mold for sand-coated molding and application of graphite mold

A technology of sand-covered molding and graphite molding, which is used in molding machines, casting molding equipment, casting molds, etc., to reduce machining allowance, reduce thermal cracking, and improve quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

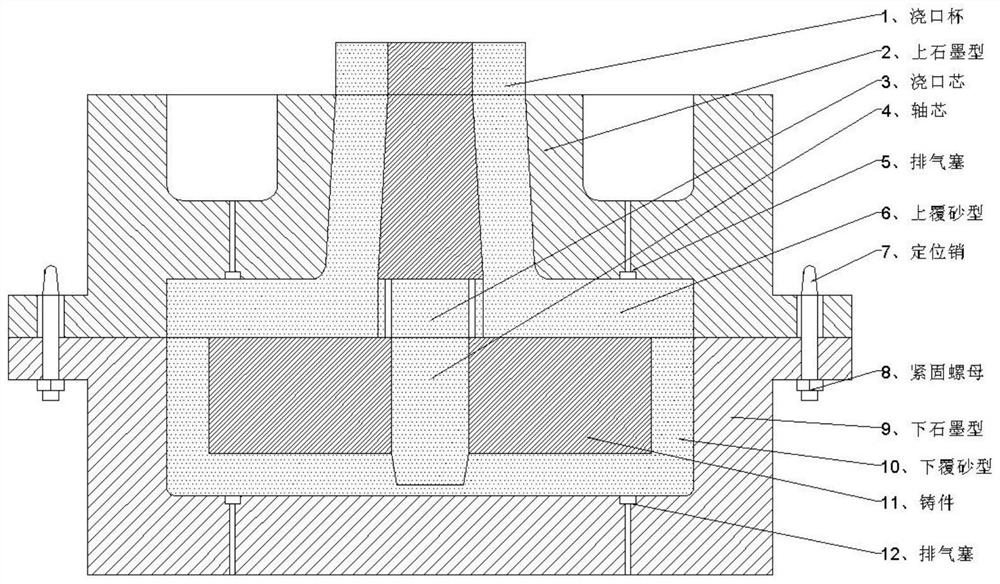

[0035] Graphite type (mounted)

[0036] Mix 85% of the graphite fillet with 15% soda glass, filled in the female mold, heated to 120 ° C, heat insulation for 60 min, thermally cured molding, and set the graphite shape.

[0037] According to the design requirements, the above graphite type is finished: 12 holes of the outer round whale φ10, one of the mouth of φ12 in the inner end of each hole, to ensure uniform exhaust gas of the sand sand layer, and the sand. Tightness.

[0038] The sand is hung in the surface of the sand, and the thickness of the sand is 15 ± 5 mm. Graphite types include: a, on graphite, B, and lower graphite type.

Embodiment 2

[0040] The graphite type of Example 1 was used to produce φ500 mm cast steel gear castings.

[0041] 1. Metal mold, according to the casting process, molding with cast iron. Metal molds include:

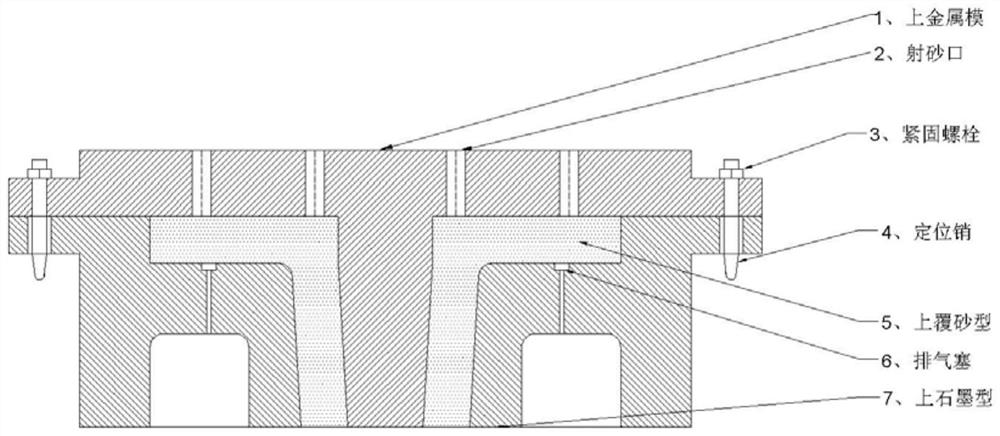

[0042] a, upper metal mold,

[0043] According to the design requirements, the upper metal mold is used in the upper metal mold, the extension is distributed into three main erades, 12 mm per width, 50 mm long, and the outer circle is 6, 10 mm per width, 15 mm long. Keep the shot, blowing channels, no short circuit, no dead angle, complete, uniformly hardened, surface jetting the molding agent, prevents the surface of the sand-bearing layer, so it is easy to demold.

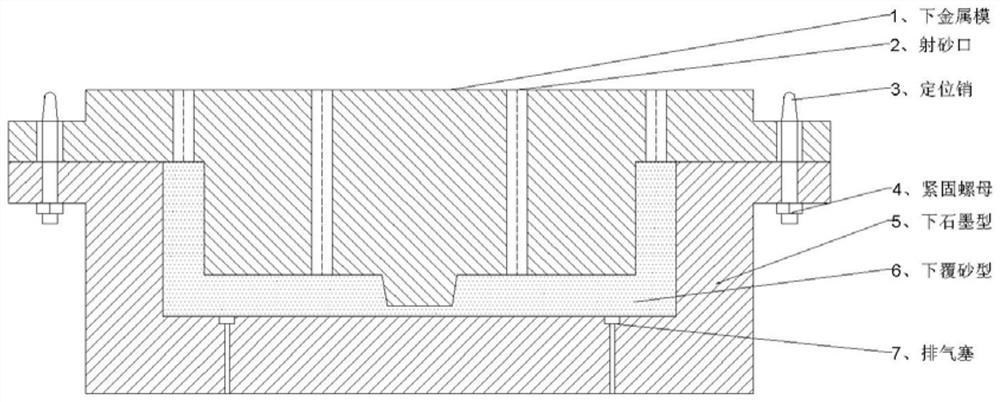

[0044] B, lower metal mold. According to the design requirements, the lower metal mold is used in the lower metal mold, and the extension circle is distributed as the main emitter, 12 mm per width, 50 mm long, and is a helpless range, 10 mm per width, 15mm long. Keep the shot, blowing channels, no short circuit, no dead ang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com