Flexible seed sowing device

A kind of seed metering device, flexible technology, applied in the direction of seeder parts, etc., can solve the problems of difficult sowing and poor fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

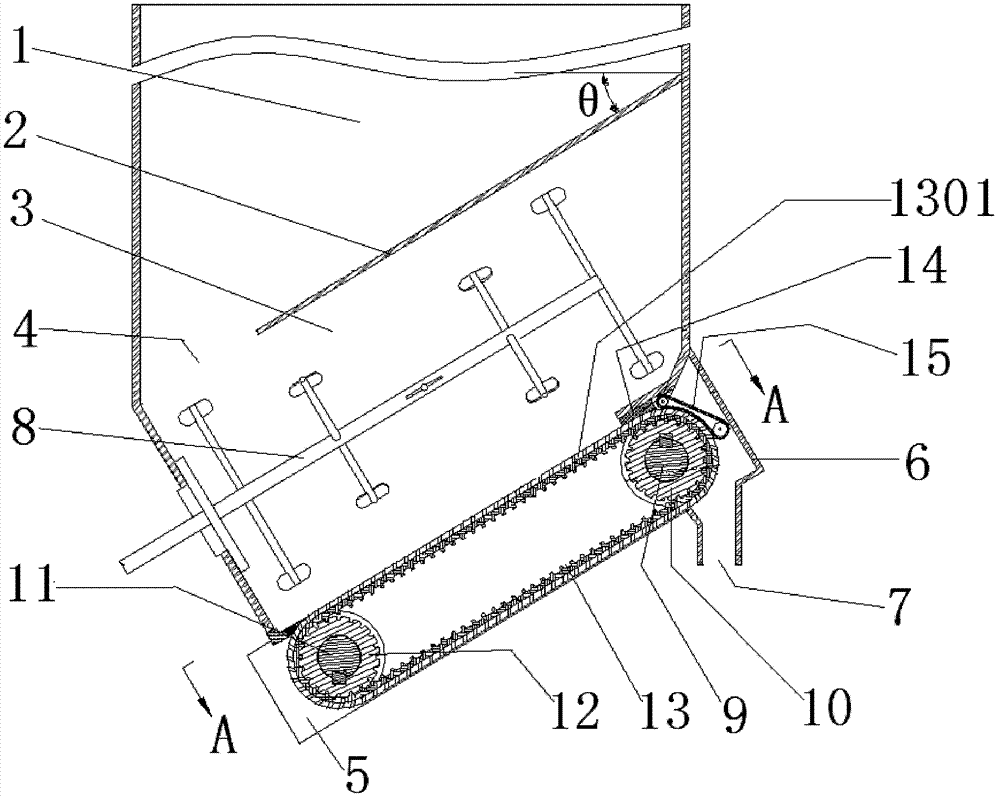

[0017] An embodiment of the present invention is a flexible seed metering device for sowing Gramineae or Leguminous forage species. The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

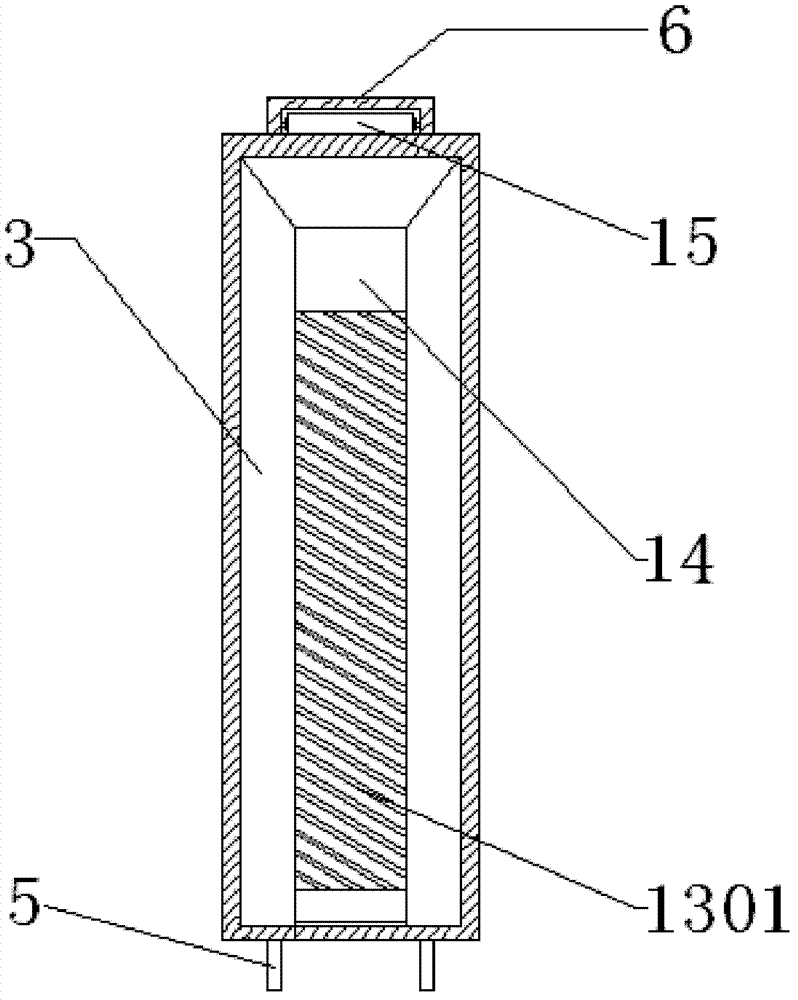

[0018] figure 1 It is a schematic diagram of the structure of the flexible seed metering device. In the flexible seed metering device, the seed box 1 is a cuboid shell, the seed filling chamber 3 is fixedly connected to the lower part of the seed box 1, and the partition 2 is inclined downward from the horizontal plane in the seed box 1 at an angle θ of 26°~45°, the partition 2 is fixed to the side wall and rear wall of the seed box 1, the partition 2 separates the seed box 1 from the seed filling chamber, and the distance between the partition 2 and the front wall of the seed box 1 For the seed channel 4. The space in the seed-filling chamber 3 is an inverted trapezoid gradually shrinking, the front wall of the seed-filling cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com