Vertical seeding disc for gravity filling

A kind of seeding disc and disc technology, which is applied in the direction of seeder parts, etc., can solve the problems of increased seed filling rate and unsatisfactory seed filling effect, and achieve the effect of good seed sorting quality, novel structure and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

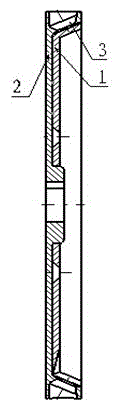

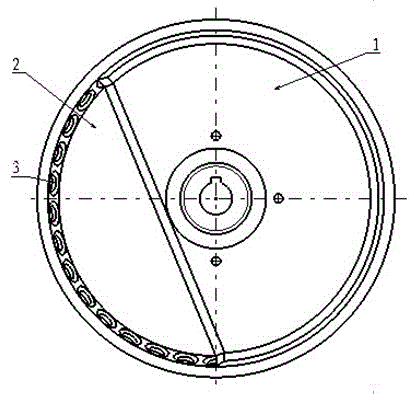

[0010] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A vertical seeding disk that can be filled with gravity. The seeding disk 2 is in the shape of a basin as a whole. 2 The side walls are evenly distributed along the circumferential direction with seed-filling holes 3, and a pot-shaped seed protection plate 1 matching it is arranged in the basin cavity of the basin-shaped seed-discharging tray 2, and the side wall of the pot-shaped seed protection plate 1 will be Part of the seed-filled hole 3 on the side wall of the pot-shaped seeding tray 2 is shielded and covered.

[0011] During operation, in the seed filling area on the lower side of the casing of the vertical disc seed metering device, the seeds are filled into the seed filling type of the rotating seed metering disc 2 under the joint action of the side pressure generated between the seeds and its own gravity. In the hole 3, under the common protec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com