Passenger vehicle tire

A technology for passenger cars and tires, applied in tire parts, reinforcement layers of pneumatic tires, vehicle parts, etc., can solve problems such as skew and straight-line stability effects, and achieve the effect of energy reduction and high-speed durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

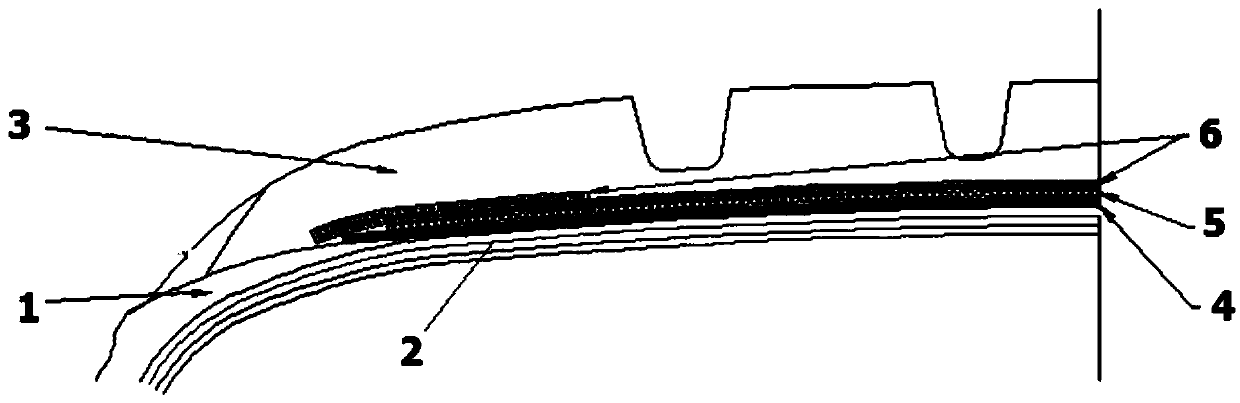

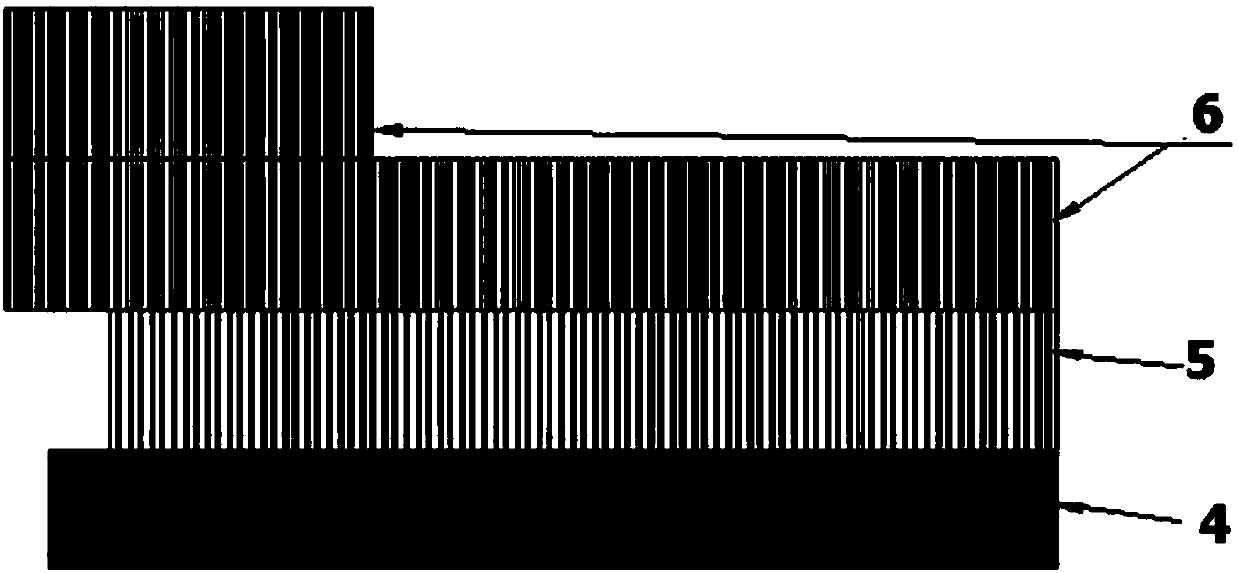

[0014] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] A passenger car tire, the tire includes a sidewall 1, a carcass 2, a tread 3 and a belt layer, the belt layer includes a steel wire belt layer 5 and a fiber belt layer 6. A hard rubber layer 4 is arranged between the steel wire belt layer 5 and the carcass 2, and the width of the hard rubber material layer 4 is greater than that of the steel wire belt layer 5, with a step difference of 5-30mm. Both sides of the hard rubber layer 4 extend to the sidewall 1 respectively, and the width of the joint between the hard rubber layer 4 and the sidewall 1 is 5-30 mm. The steel wire belt layer 5 is one layer, the angle of the steel wires in the steel wire belt layer 5 is 0-5 degrees, and the steel wire belt layer 5 is formed by winding rubber-coated steel wires at an angle of 0-5 degrees. The fiber belt layer 6 is arranged on the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com