Pneumatic tire

A pneumatic tire, tire circumferential technology, applied to the reinforcement layer of pneumatic tires, tire parts, textiles and papermaking, etc., can solve the problems of difficult to ensure high-speed durability, reduced adhesion durability, etc., to ensure the rigidity of the cord , High-speed durability improvement, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

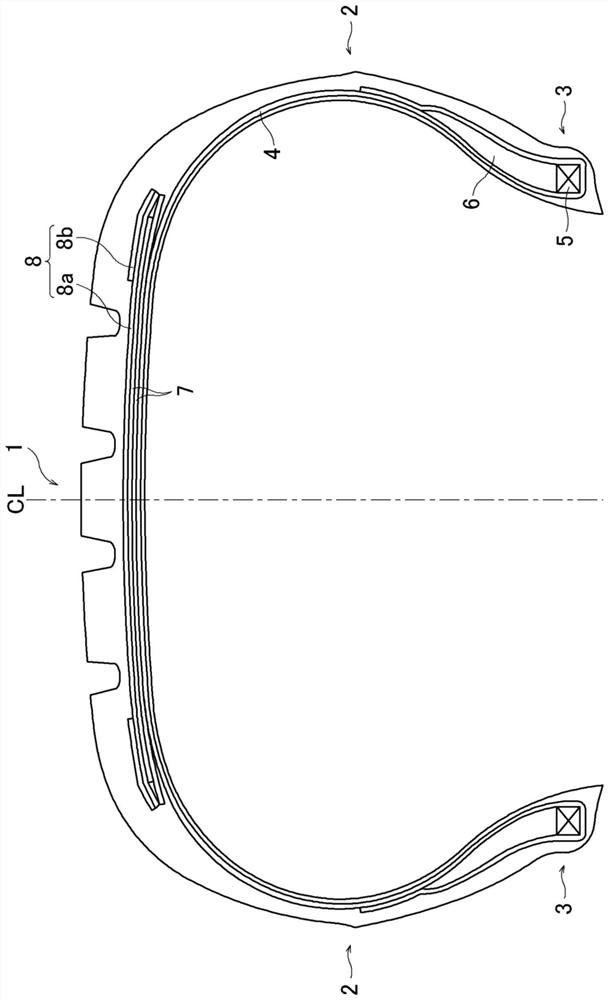

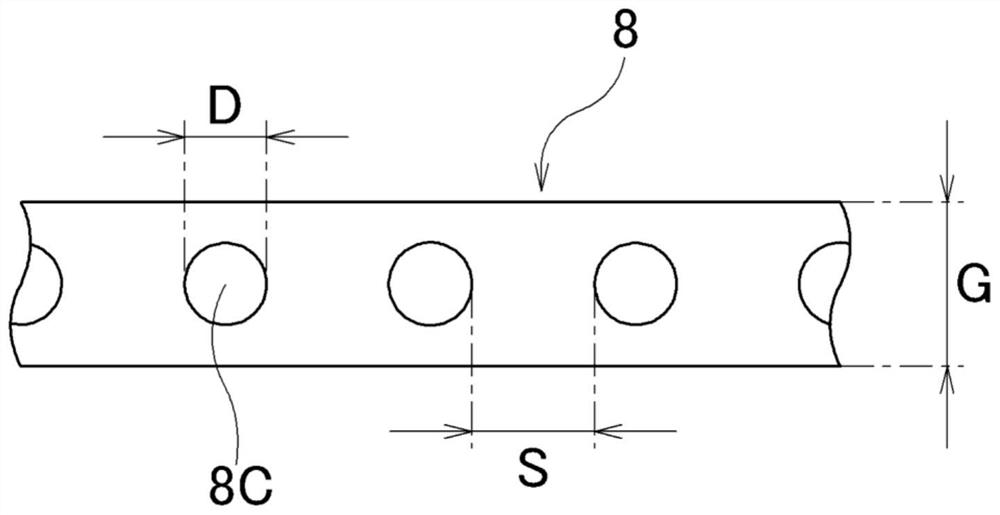

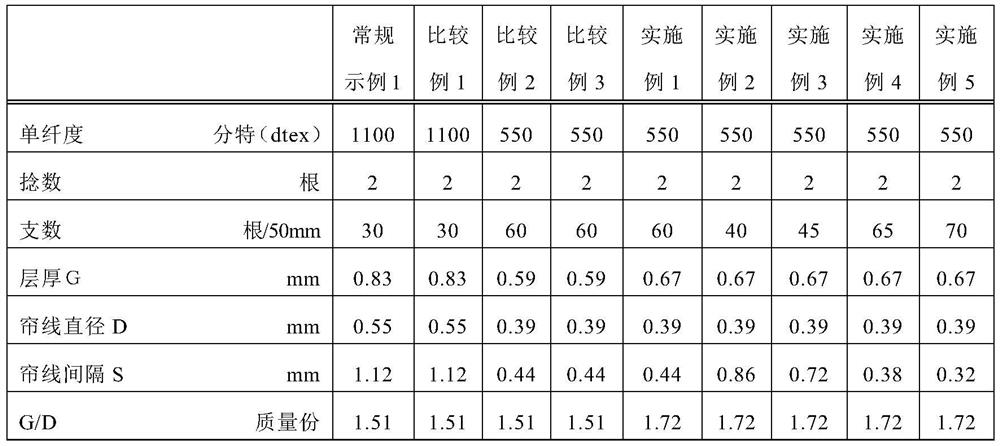

[0033] The tires of Conventional Example 1, Comparative Examples 1-4, and Examples 1-10 under different conditions as shown in Tables 1-2 were manufactured. The conditions are as follows: the tire size is 195 / 65R15, with figure 1 The basic structure shown, the single fineness of the organic fiber cord constituting the belt cover layer, the number of undertwisted yarns constituting the organic fiber cord (number of twists), and the beating density of the organic fiber cord in the belt cover layer (count), layer thickness G of the belt cover layer, cord diameter D of the organic fiber cord, cord spacing S between organic fiber cords adjacent in the tire width direction in the belt cover layer, layer thickness The ratio G / D of G to the cord diameter D, the ratio S / D of the cord spacing S to the cord diameter D, the number of twists of the organic fiber cord, and the middle of the 2.0 LN / dtex load of the organic fiber cord Elongation.

[0034] In each example, the belt covering l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com