Pneumatic tires for vehicles with straps

A technology for pneumatic tires and vehicles, applied to the reinforcement layer of pneumatic tires, vehicle parts, tire parts, etc. Small, reduced rolling resistance, good high-speed durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

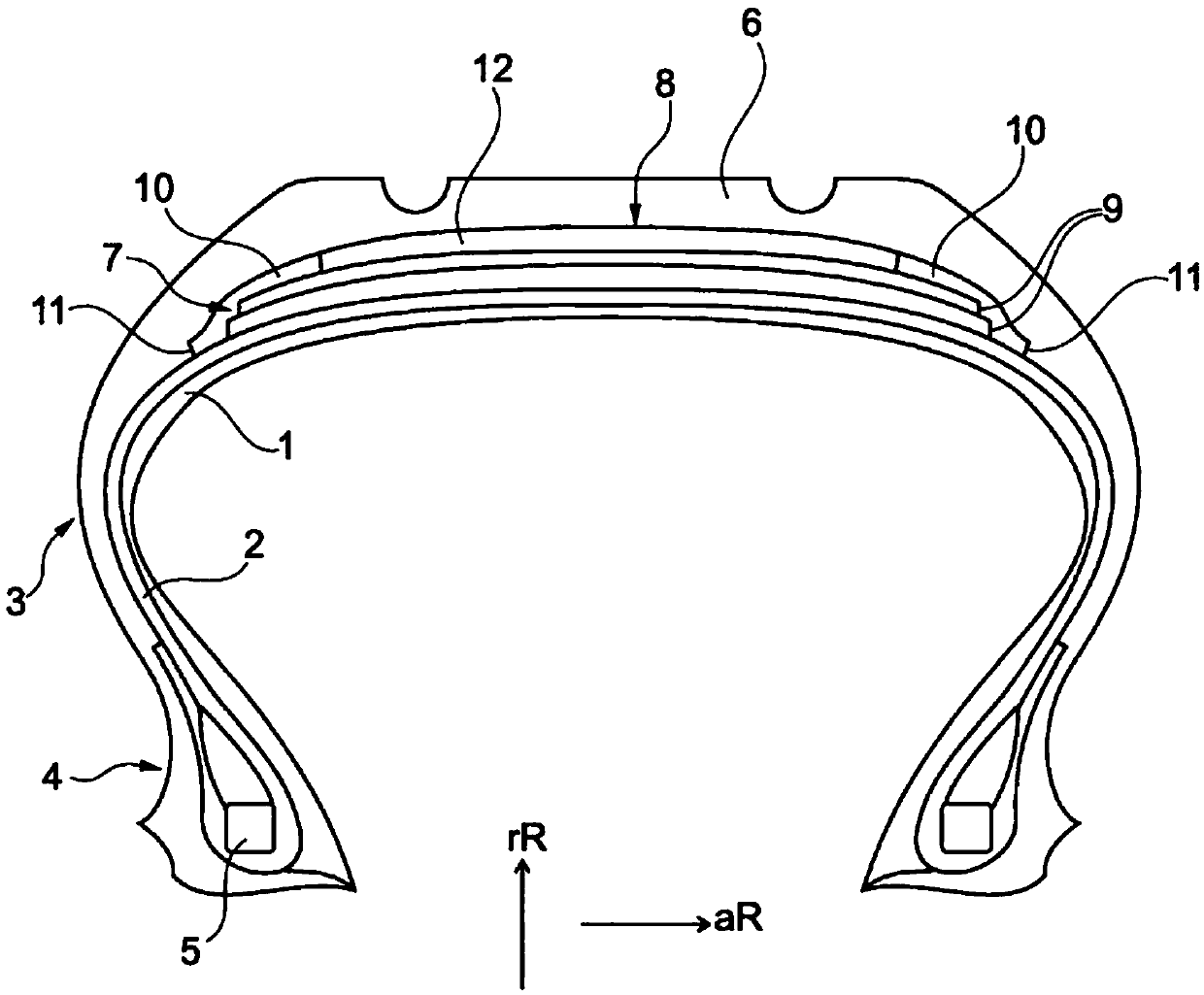

[0035] figure 1 A radial cross section through a vehicle pneumatic tire for passenger cars is shown. The main components that make up the pneumatic vehicle tire shown are: a largely air-impermeable inner layer 1, a carcass 2 (the carcass starts in a conventional manner from the apex region of the pneumatic tire for vehicles, passes through the sides 3, and ends in into the bead area 4 and anchored in the bead area by coiling the stretch-resistant bead core 5), the shaped tread 6 located radially outside the carcass, and between the tread 6 and the tire Arranged between the bodies 2 is a cord strip 7 comprising two reinforcing carrier layers, which cord strip is covered radially on the outside with a belt band comprising a band layer 8 . The band layer covers the cord belt edges 9 and contains reinforcing carriers coiled in parallel along the axial width in the circumferential direction of the vehicle pneumatic tire.

[0036] The cuff layer 8 comprises in its axial extension...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com