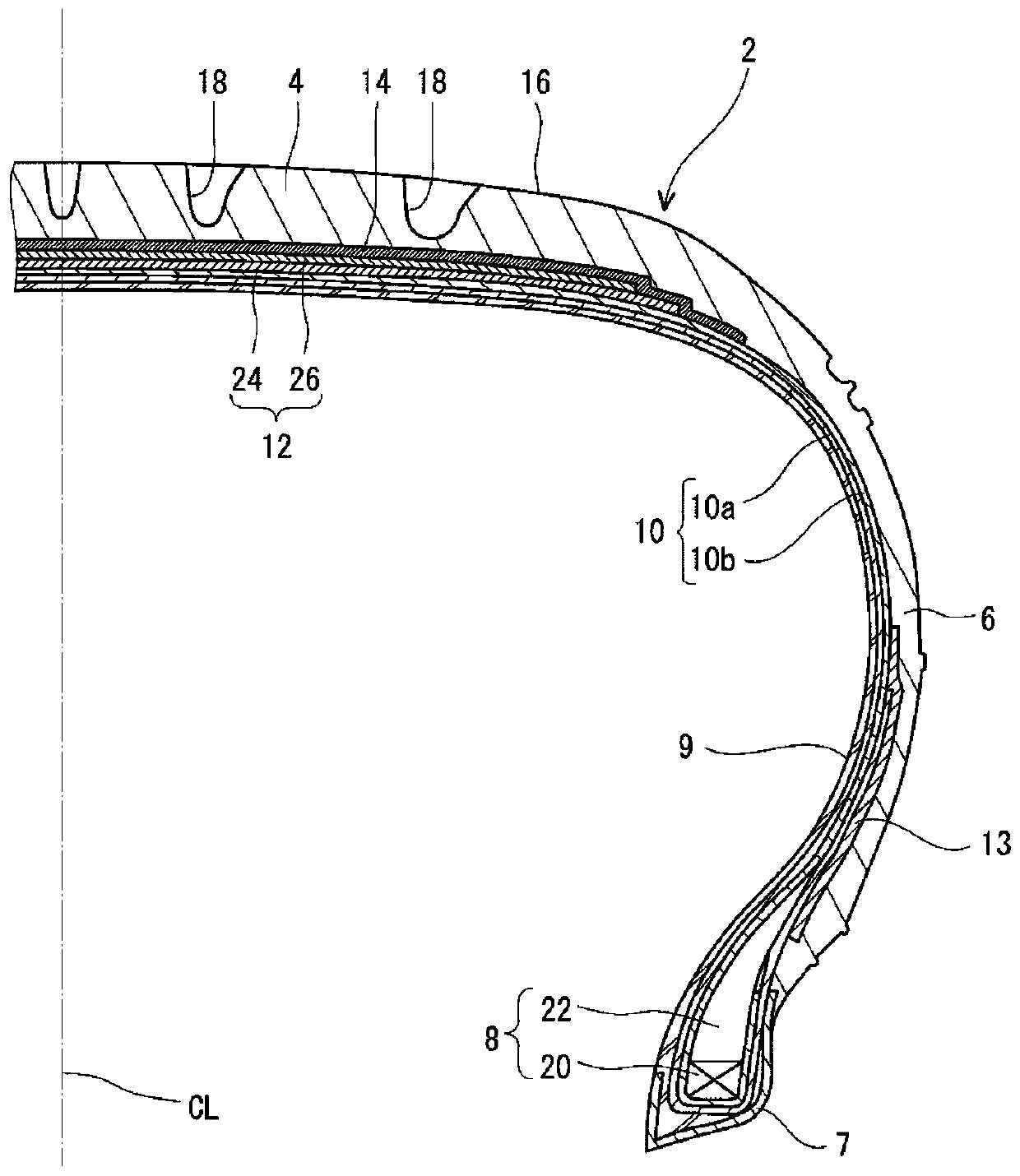

Adhesive composition for organic fiber, method for treating organic fiber, organic fiber, and tire

A technology for organic fibers and compositions, applied in the field of adhesive compositions for organic fibers, can solve problems such as reduced adhesive force and reduced adhesiveness, and achieve the effects of excellent high-speed durability and excellent heat-resistant adhesiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

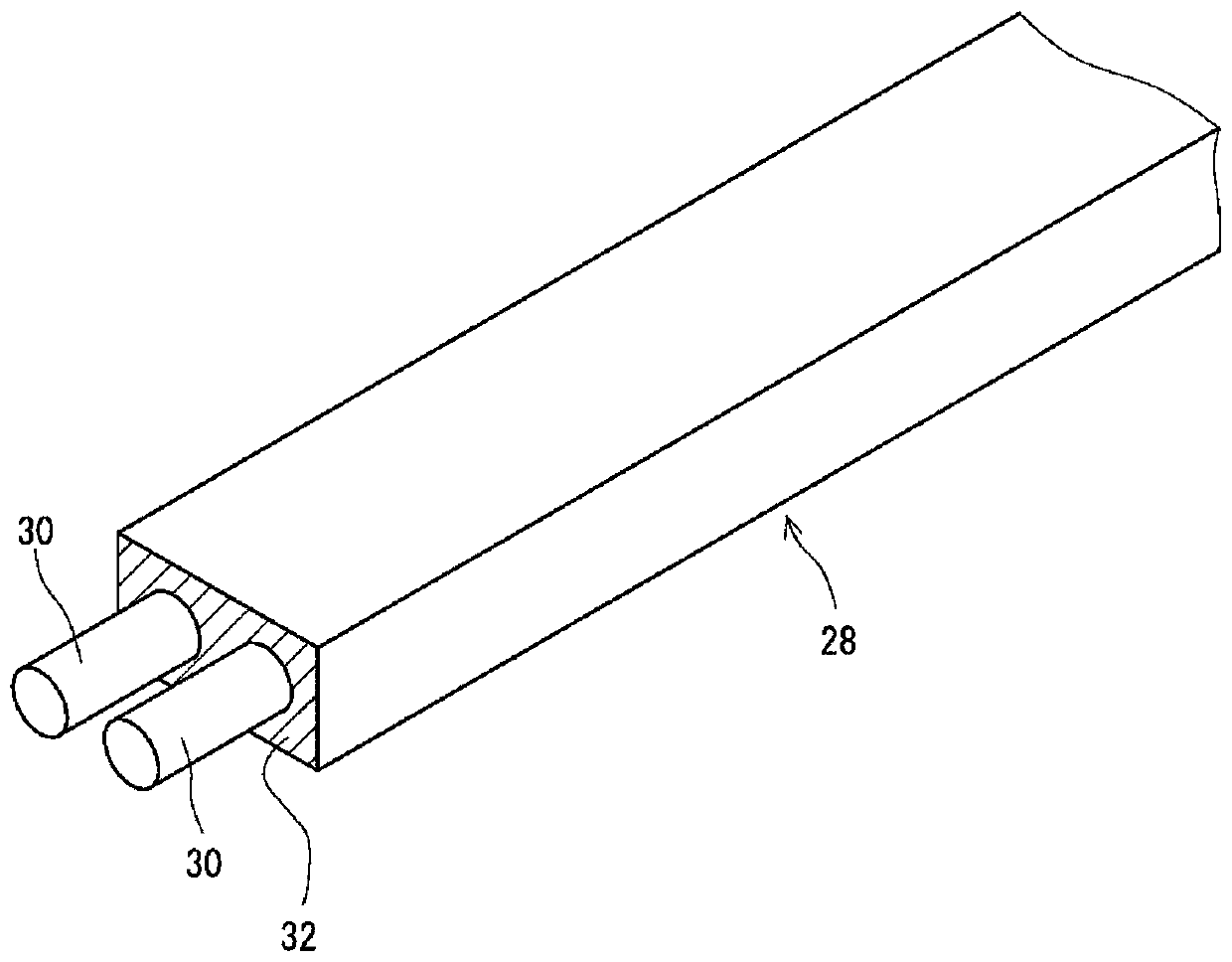

Method used

Image

Examples

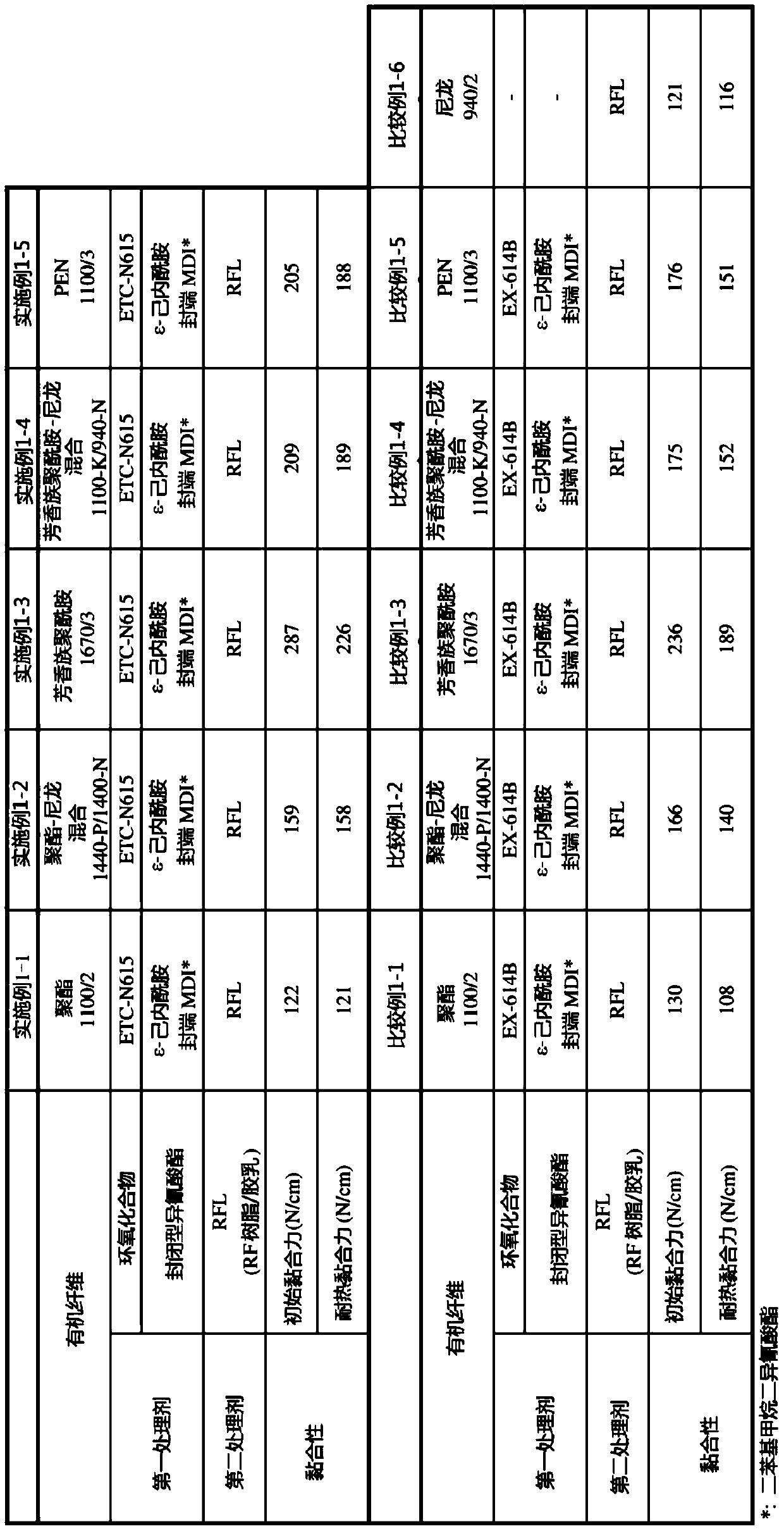

Embodiment 1-1

[0160]A binder composition for organic fibers was prepared as a first treatment agent by the following method: While stirring water, 11.8 g of ETC-N615 (sorbitol polyglycidyl ether, chlorine content: 9.3% by weight) was added to 920 g of water , epoxy equivalent: 163, manufactured by Nagase ChemteX Corporation) as an epoxy compound, and 72.1 g of ε-caprolactam-blocked diphenylmethane diisocyanate aqueous dispersion (54% concentration) was added thereto as a blocked isocyanate.

[0161] Prepare the RFL liquid as rubber latex by the following method: Dilute 172g of Nipol 2518FS (manufactured by Nippon Zeon Co., Ltd., vinylpyridine-styrene-butadiene terpolymer water emulsion with 76g of water, total solid content concentration : 40.5%) and 73g of Nipol LX-112 (manufactured by Japan Zeon Co., Ltd., styrene-butadiene copolymer 41% water emulsion, total solid content concentration: 40.5%), and while slowly stirring the diluent , add 270g of resorcinol-formaldehyde initial condensati...

Embodiment 1-2

[0164] Process the organic fibers in the same manner as in Example 1-1, except that: use polyester-nylon hybrid cords (the composition of the cords: 1440-P / 1400-N (dtex), the twist of the cords: 34 (number of twists / 10 cm), cord diameter: 0.67 mm, number of warp yarns: 49 cords / 5 cm) as organic fibers. Initial adhesion and heat-resistant adhesion were measured on treated polyester-nylon hybrid cords (organic fibers). The results are shown in Table 1.

Embodiment 1-3

[0166] Treat organic fibers in the same manner as in Example 1-1, except that aramid cords are used (the composition of the cords: 1670 / 3 (dtex), the twist of the cords: 40 (number of twists / 10cm ), cord diameter: 0.85mm, number of warp yarns: 35 cords / 5cm) as organic fibers. Initial adhesion and heat-resistant adhesion were measured for the treated aramid cord (organic fiber). The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com