Drag reducing and speed increasing pipeline with microporous inner wall

A pipeline and microporous technology, applied in the direction of mechanical equipment, fluid flow, etc., can solve the problems of unsuitable environment for single-phase flow, weakening, and destruction of microbubbles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

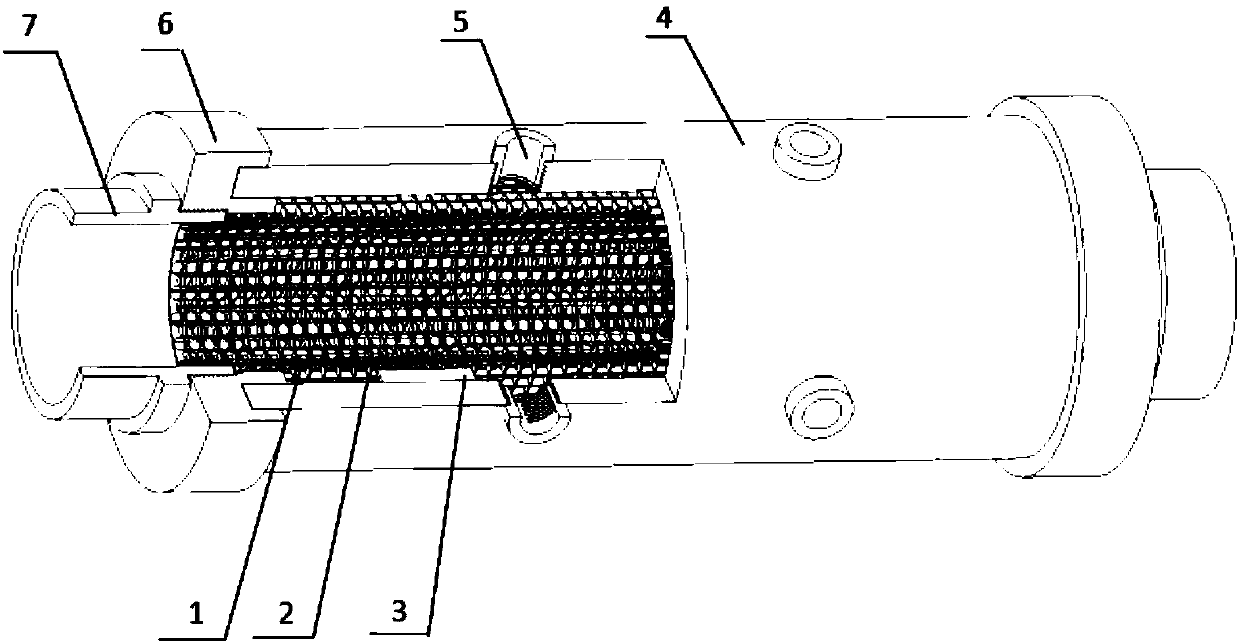

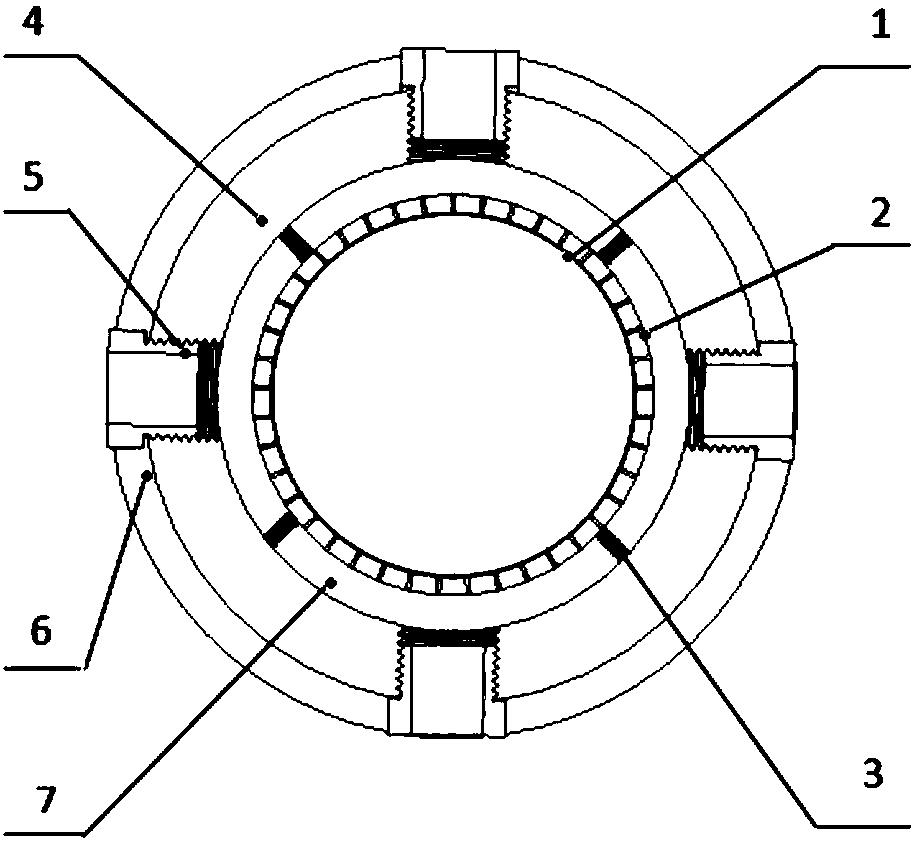

[0024] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. Such as figure 1 The invention shown is a pipe that regulates the flow rate and pressure of fluid within the pipe. Including: porous inner sleeve 1, stencil support sleeve 2, support body 3, outer sleeve 4, pneumatic joint 5, flange 6, pipe joint 7.

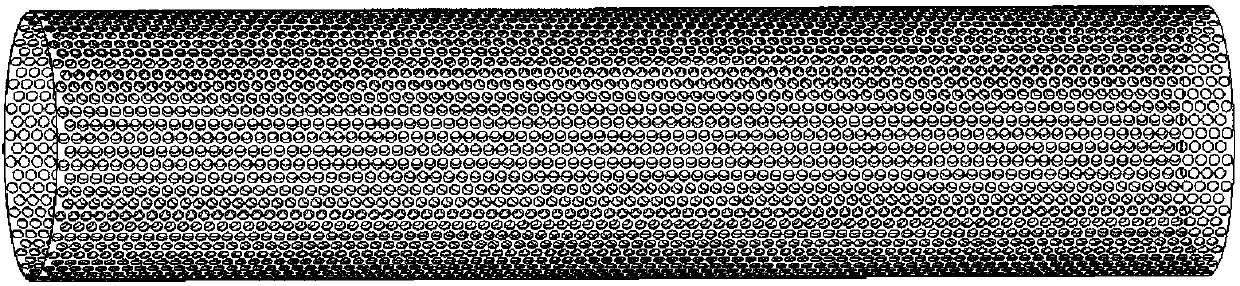

[0025] The porous inner sleeve 1 is the main part in contact with the fluid, and forms a micro-air chamber on the inner wall of the pipeline. The gas-liquid two-phase contact reduces the pressure loss on the wall compared with the single-phase contact of the liquid phase. The outer wall surface of the porous inner sleeve 1 is adhered to the mesh support sleeve 2, and the two form a nested structure. Micro-square holes are evenly distributed on the screen support sleeve 2 . A plurality of rectangular support bodies 3 are adhered to the outer wall surface of the screen support sleeve 2 . The support body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com