High-temperature tensile testing machine

A tensile testing machine, high-temperature technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of inability to test the tensile strength of materials, and achieve the effect of ensuring accuracy and uniform temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

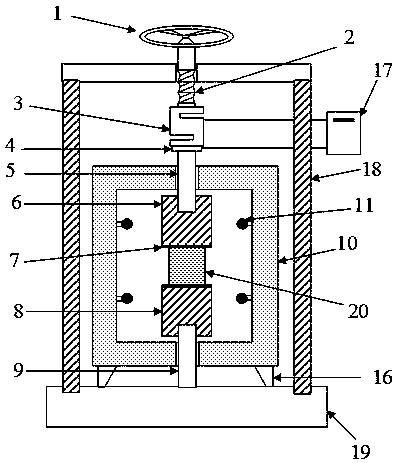

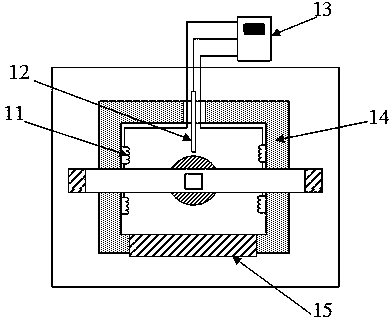

[0022] Such as figure 1 with figure 2 As shown, a high-temperature tensile testing machine provided by the present invention includes a hand wheel 1, an adjusting screw 2, a pressure sensor 3, a displacement sensor 4, an upper connecting rod 5, a tensile end 6, a high-temperature-resistant adhesive 7, a fixing End 8, lower connecting rod 9, high temperature electric heating furnace 10, heating element 11, temperature measuring element 12, temperature control device 13, furnace wall 14, furnace door 15, support frame 16, measuring system 17, pressurized frame 18, base 19. Rock and soil samples 20, etc.; the high-temperature electric heating furnace 10 has holes at the top, bottom and rear of the furnace wall 14; the handwheel 1 is fixed on the pressurized frame 18, and the handwheel 1 and the The pressure sensor 3 and the displaceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com