A test tool and test method for standard support and hanger of nuclear grade pipeline

A support and hanger technology, which is applied in the field of standard support and hanger test tooling for nuclear-grade pipelines, can solve the problems of unspecified test tooling test methods, and achieve the effect of easy disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

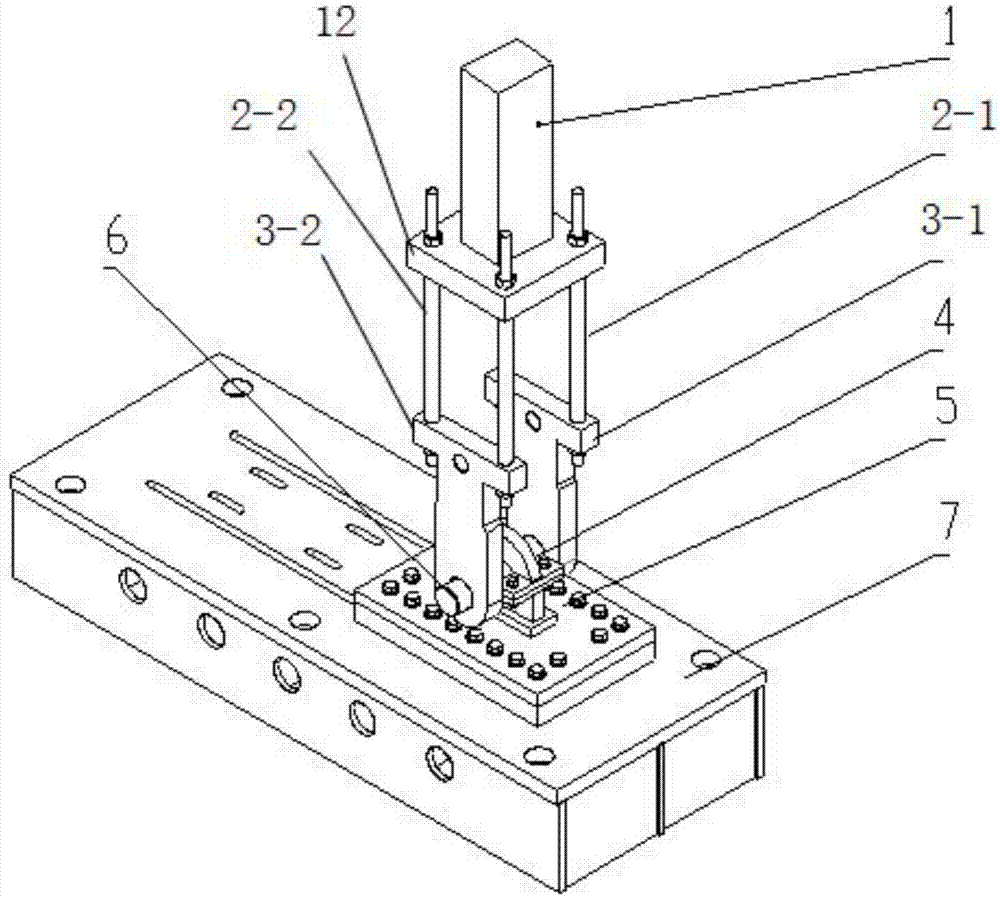

[0053] figure 1 It shows a standard support and hanger test fixture for nuclear grade pipelines when the angle between the load direction of the support pipe clamp and the horizontal direction is 90°, which includes:

[0054] The test main stand 7 is fixed on the ground;

[0055] Tooling assembly, the tooling assembly is adjustably installed on the test main frame 7, the tooling assembly includes an adjustment connecting plate 5, and a plurality of bolts are provided on the test main frame 7 and the adjusting connecting plate 5 Bolts pass through the bolt holes and cooperate with nuts to detachably connect the adjustment connecting plate 5 to the test main frame 7; at the same time, the bracket pipe clamp 4 can be installed on the above-mentioned adjusting connecting plate 5, so that all The position of the bracket pipe clamp 4 is fixed. It should be noted that the adjustment connecting plate 5 can be installed to different positions of the test main frame 7 through the bolt...

Embodiment 2

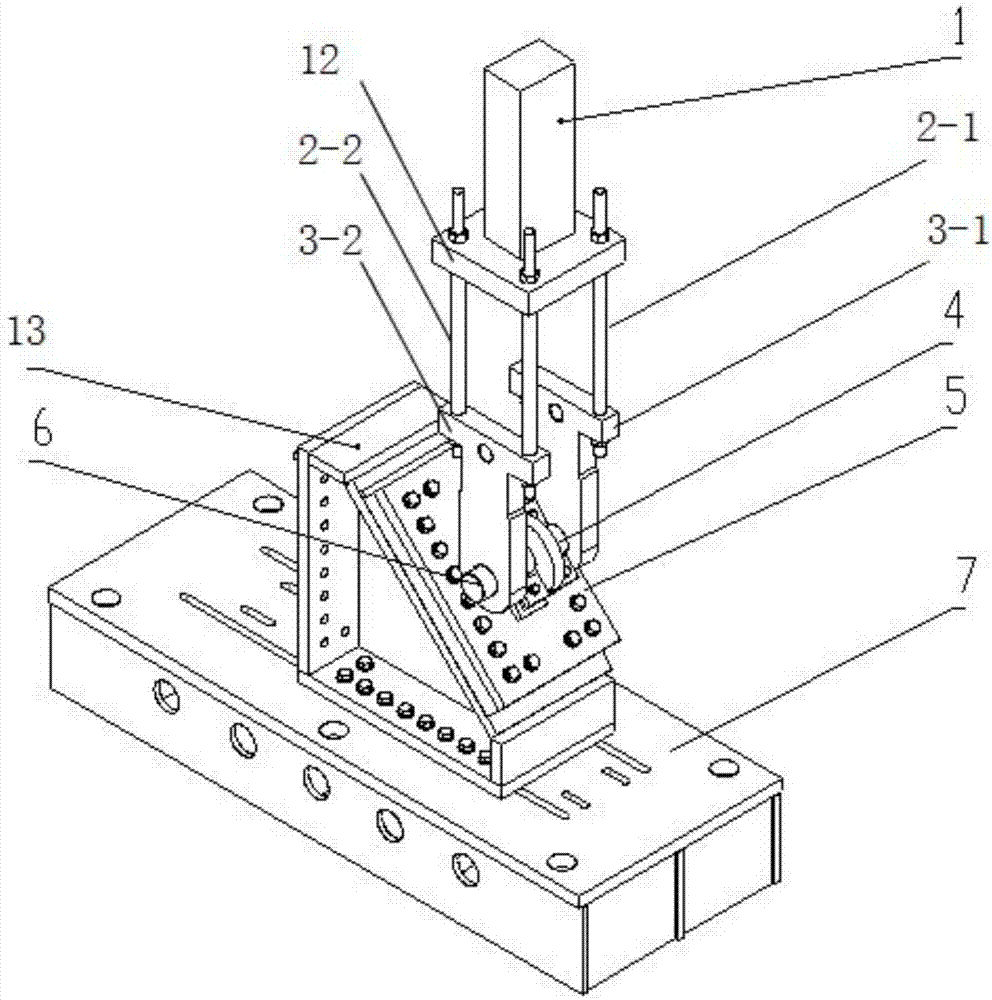

[0061] image 3 It shows a standard support and hanger test fixture for nuclear-grade pipelines when the angle between the load direction of the bracket pipe clamp and the horizontal direction is 45°. The difference between this embodiment and Embodiment 1 is that the tool assembly includes an adjustment connection Plate 5 and triangular-shaped tooling 13; wherein the triangular-shaped tooling 13 is a right-angled triangle as a whole, including two right-angled side plates and a slanted plate, for detachably connecting the adjusting connecting plate 5 .

[0062] Specifically, a plurality of bolt holes are provided on the two right-angle side plates, a slant plate, the test main frame 7 and the adjustment connecting plate 5, and the bolts pass through the bolt holes and cooperate with nuts, and the adjusting connecting plate 5 is detachably connected to the inclined plate, and any one of the right-angle side plates is detachably connected to the test main frame 7, so that the p...

Embodiment 3

[0065] Figure 4 It shows a standard support and hanger test tooling for nuclear grade pipelines when the angle between the load direction of the bracket pipe clamp and the horizontal direction is 0°, and the tooling assembly also includes an adjustment connecting plate 5 and a triangular tooling 13; wherein the The triangular-shaped tooling 13 is a right-angled triangle as a whole, including two right-angled side plates and a slanted plate for detachably connecting the adjusting connecting plate 5 . The difference from Embodiment 2 is that the two right-angled side plates, one slant plate, the test main frame 7 and the adjustment connecting plate 5 are all provided with a plurality of bolt holes, and the bolts pass through the bolt holes and cooperate with the nuts. The adjustment connecting plate 5 is detachably connected to any one of the right-angled side plates, and the other right-angled side plate is detachably connected to the main test frame 7, so that the triangular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com