Disposable quantitative dosing group cup

A one-time, quantitative hole technology, used in laboratory utensils, laboratory containers, chemical instruments and methods, etc., can solve problems such as cumbersome operation, bacterial contamination, and easy environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

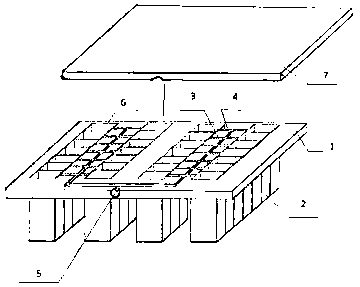

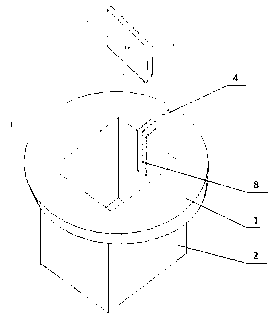

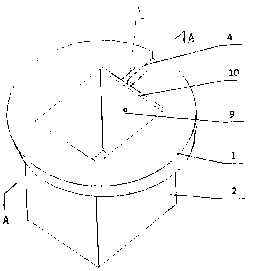

[0013] Example 1, such as figure 1 As shown in the figure, a connection plate 1 made of transparent material is installed in the disposable quantitative dosing group cup. One side of the connection plate is connected with multiple sets of test cups 2, and the surface of the other side of the connection plate is opened with a plurality of groove-like flow channels. , the flow channel is composed of a main channel 3 and a branch channel 4, the mouth 6 of the test cup 2 is opened on the side forming the flow channel through the connecting plate 1, the main channel 3 and the liquid inlet 5 opened on the connecting plate One end of the tributary channel 4 is connected with the main channel 3, and the other end of the tributary channel 4 is connected with the cup mouth 6 of the test cup. There is a groove 11 extending downward about 6mm long at the intersection along the cup wall. The plate 10 is attached to the groove to form a descending branch channel 8, such as figure 2 As sho...

Embodiment 2

[0016] Embodiment 2, the main structure of this embodiment is the same as that of Embodiment 1, the only difference is the structure of the quantitative hole 9 and the connected descending branch flow channel 8, as described in the scheme, this embodiment is directly connected to one end of the branch flow channel 4 There is a section of blind hole 12 on the wall of the connected test cup, instead of the descending branch flow channel 8 in embodiment 1, a certain amount of hole 9 is horizontally opened on the test cup wall at the lower end of the blind hole, and connected with the blind hole, such as Figure 5 , 6 As shown, the quantitative hole is connected to the inner cavity of the test cup, and a cover plate 7 is pasted on the surface of the connecting plate 1 to seal all the flow channels and the cup mouth.

[0017] In this embodiment, the diameter of the blind hole 12 is about 1 mm, and the depth is about 6 mm. The diameter of the quantitative hole 9 is about 1 mm, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com