LED power source production line

A LED power supply and production line technology, applied in the field of mechanical equipment, can solve problems such as easy congestion, easy movement obstruction, and inability to remove LED power supplies, achieving neat and beautiful wiring effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

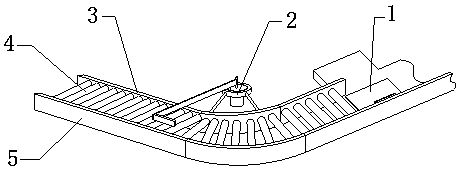

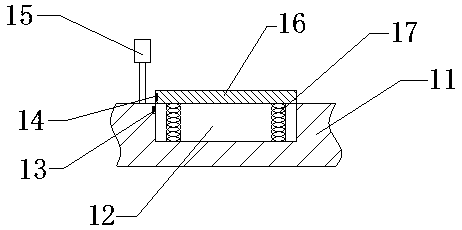

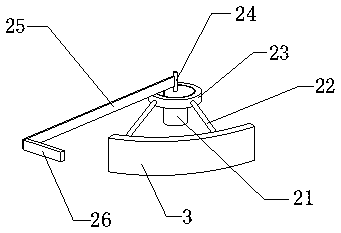

[0021] see Figure 1-Figure 3 , the present invention provides a technical solution: a LED power supply production line, including a defective product rejecting mechanism 1, an auxiliary turning mechanism 2, an inner frame 3, a supporting roller 4 and an outer frame 5, and the inner frame 3 passes through the supporting roller 4 and the outer frame 5-phase connection, the unqualified product rejecting mechanism 1 includes a diverter plate 11, a square groove 12, an indicator light 15, a bearing plate 16 and a spring 17, and the auxiliary turning mechanism 2 includes a motor 21, a connecting rod 22, a disc 23, a rotating shaft 24, Toggle plate 25 and movable plate 26.

[0022] In the unqualified product rejecting mechanism 1, the diverter plate 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com