Electric energy meter standard wiring device and using method thereof

A standard wiring and electric energy meter technology, applied in the direction of measuring devices, measuring electric variables, instruments, etc., can solve the problems of limited wiring length between electric energy meter and junction box, unguaranteed pure manual wiring process, high finger strength requirements, etc. Achieve good economic benefits and market prospects, low manufacturing costs, and standardized construction techniques

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

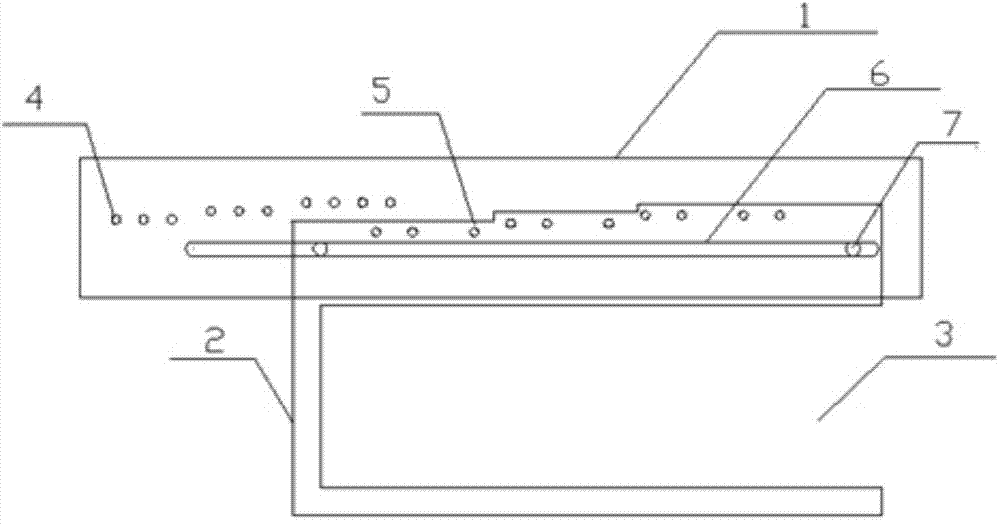

[0029] A standard wiring device for electric energy meters, the device includes a motherboard 1 and a sub-board 2 fixedly connected to the motherboard 1, the motherboard 1 adopts a rectangular insulating board with a size of 30cm×4cm×0.5cm, and the motherboard 1 is provided with ten The fulcrum holes 4 of the motherboard are 0.3cm in diameter, and the ten fulcrum holes are arranged on the motherboard 1 in three layers. Among them, three fulcrum holes are arranged horizontally on the first layer, which are connected with the electric energy meter U in turn. The current inlet, voltage wire, and current outlet are vertically corresponding; the second layer is horizontally equipped with three motherboard fulcrum holes, which are in turn vertically corresponding to the current inlet, voltage wire, and current outlet of the V phase of the electric energy meter; The third layer is horizontally equipped with four motherboard fulcrum holes, which are in turn vertically corresponding to ...

Embodiment 2

[0034] A standard wiring device for electric energy meters, the structure of which is as described in Embodiment 1, the difference is that, in order to avoid wrong wiring, digital wiring signs or engraved numbers are correspondingly pasted below the fulcrum holes of the mother board and the fulcrum holes of the sub-board Wiring identifier symbols. In this way, during the wiring process, the operator can perform wiring according to the digital wiring marks, which ensures the accuracy of wiring.

Embodiment 3

[0036] The method of using the standard wiring device of the electric energy meter to connect the three-phase four-wire electric energy meter in the metering room includes the following steps,

[0037] (1) Insert the opening slot 3 on one side of the sub-board 2 into the junction box, so that the fulcrum hole 5 of the sub-board is perpendicular to the three outlets of each phase of U, V, and W on the junction box and the neutral line hole correspond;

[0038] (2) Loosen the bolts, pull the mother board 1 through the chute 6, adjust the relative position of the mother board 1 and the daughter board 2, place the mother board 1 under the electric energy meter, and make the main board fulcrum hole 4 align with the electric energy meter in turn The three outlets of each phase of U, V, and W on the board are vertically corresponding to the zero line hole, and the bolts are tightened to fasten the mother board 1 and the daughter board 2 together;

[0039] (3) Use a screwdriver to in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com