Steam valve assembly and electric cooker having same

A technology of steam valves and components, which is applied in cooking utensils, household appliances, applications, etc., can solve the problems of poor bubble breaking and reflux capabilities, and poor anti-overflow performance, so as to achieve easy bubble breaking and reflux, reduce discharge volume, and improve anti-foaming. The effect of spillover performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to understand the above-mentioned purpose, features and advantages of the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that, in the case of no conflict, the embodiments of the present application and the features in the embodiments can be combined with each other.

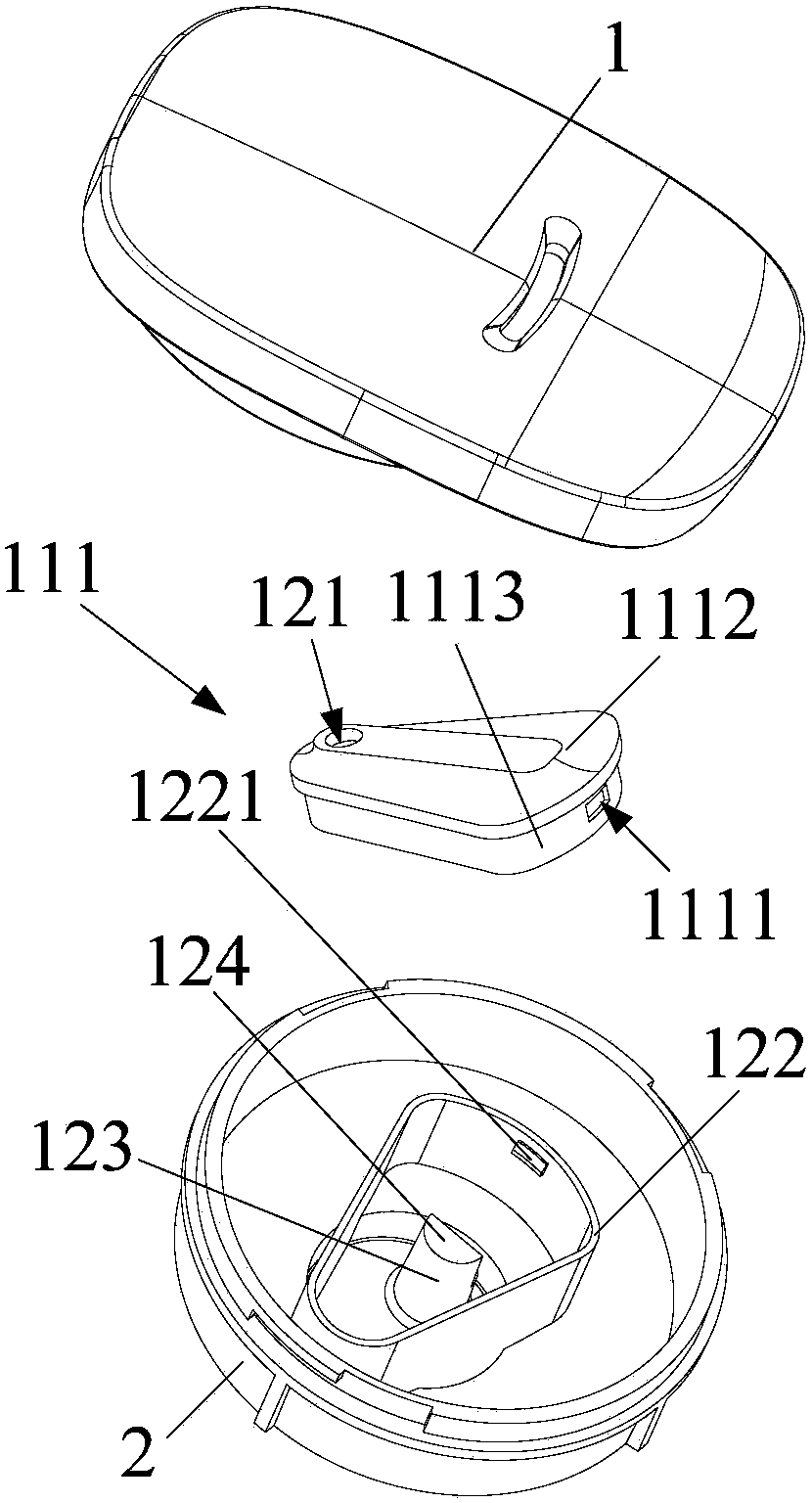

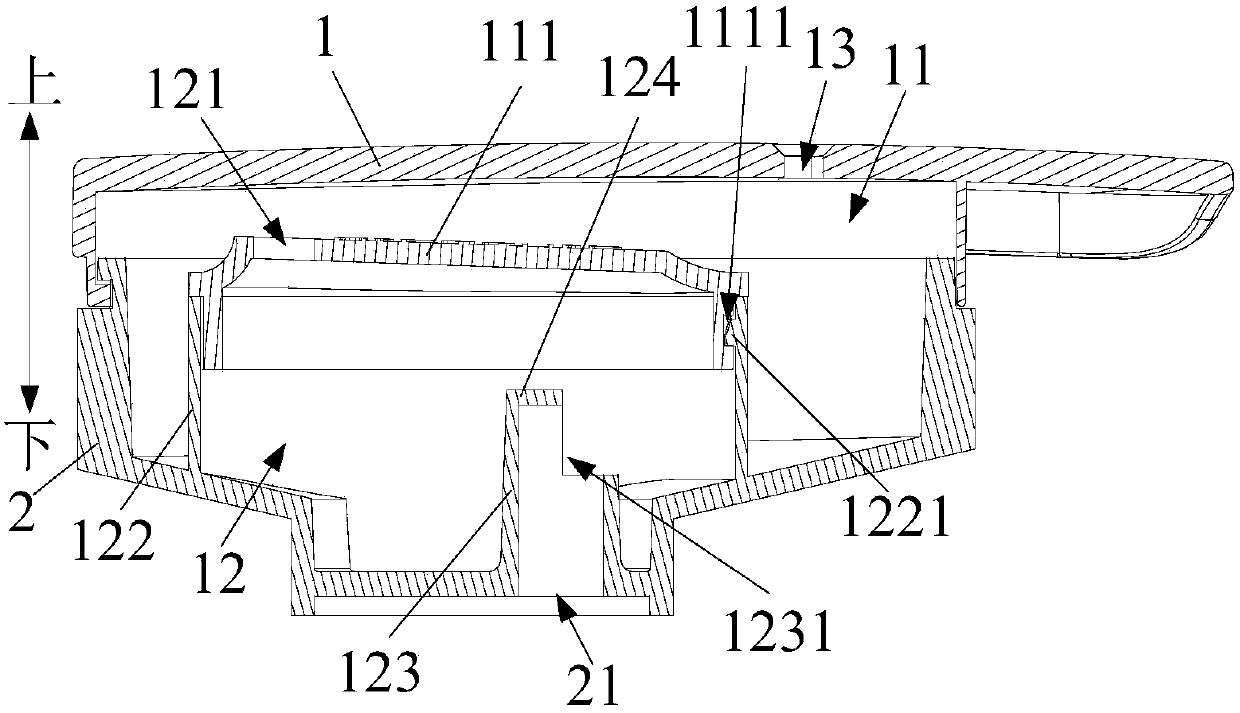

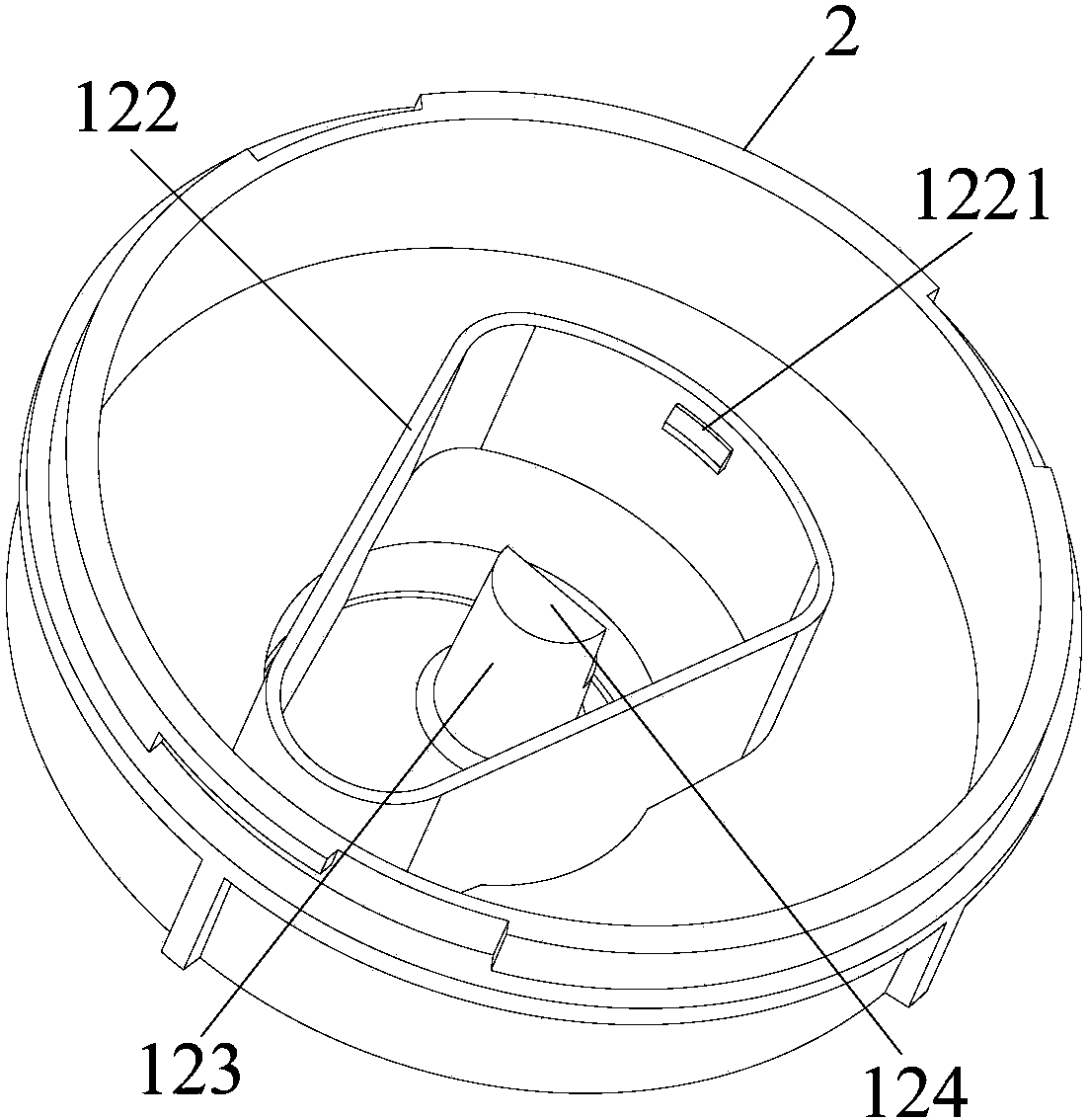

[0028] Such as Figure 1 to Figure 4 As shown, the present invention provides a steam valve assembly, including a valve seat 2 and a valve cover 1, the valve cover 1 covers the valve seat 2 and forms a first cavity 11 between the valve seat 2, A cover plate 111 is provided in the first cavity 11, and the cover plate 111 is connected to the valve seat 2, and a second cavity 12 is formed between the valve seat 2 and the cover plate 111. The valve seat 2 is provided with a steam inlet 21 communicating with the second cavity 12, the second cavity 12 communicates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com