ECU software false prevention test burning equipment

A technology for burning equipment and software, applied in electrical testing/monitoring, etc., can solve problems such as wrong installation and low efficiency, and achieve the effect of preventing adverse consequences and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

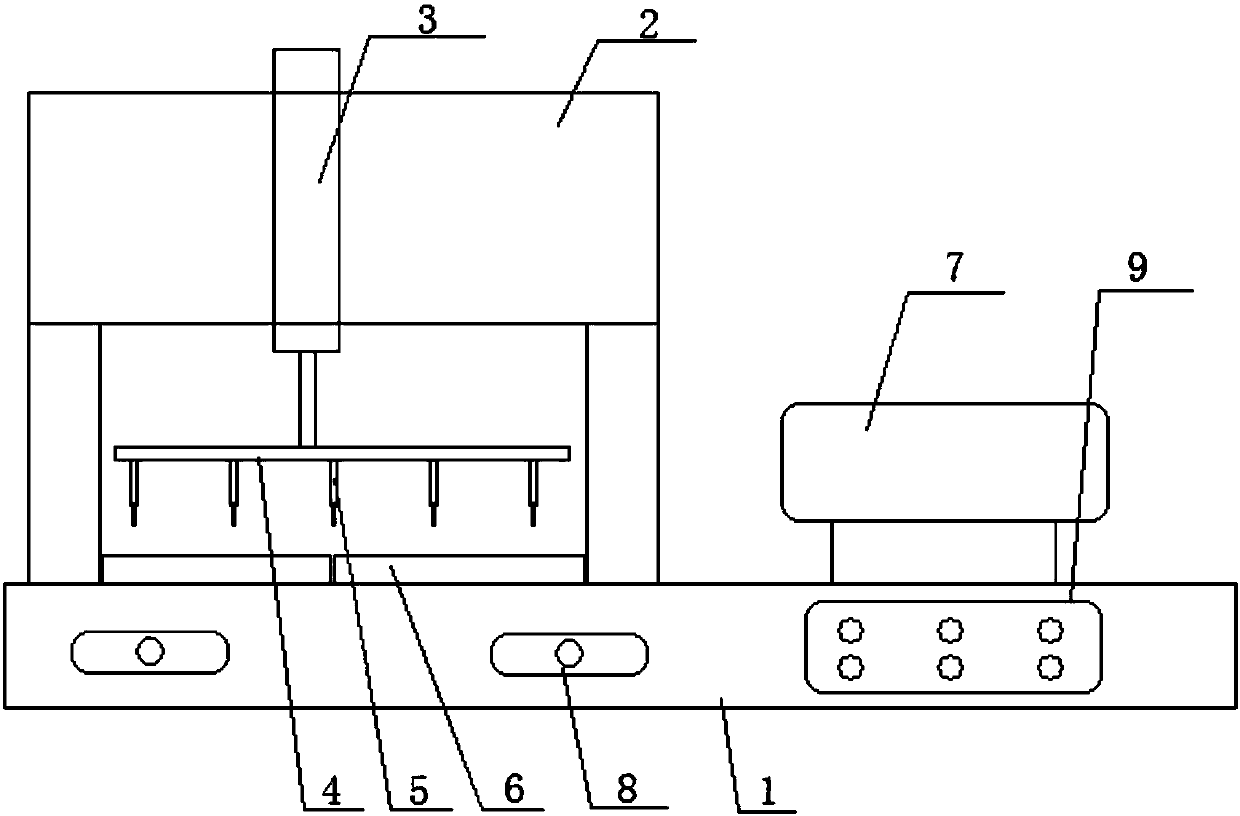

[0020] Such as figure 1 As shown, the base 1 of the device is provided with a read-write board 6 horizontally, and the read-write board 6 is used to electrically connect with the communication interface of the ECU to complete the reading and writing work of the ECU. In order to improve work efficiency, the read-write board 6 is provided with Four form four jigsaw boards, fixed side by side on the base 1, and each read-write board 6 is connected with the controller (ECU continuous test control system).

[0021] The controller is installed in the base 1, and the read-write board 6 reads the serial number information of the ECU through the electrical connection with the ECU and sends it to the controller. At the same time, the controller burns the pre-stored software program into the ECU through the read-write board 6 .

[0022] In order to ensure the reliability of the connection between the ECU and the read-write board 6, the base 1 is provided with a support 2, and the support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com