Construction method of integrated layered filling device

A filling device and construction method technology, applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve the problems that single-layer filling tools cannot be filled in layers and are difficult to move, so as to avoid sand settlement and overcome connection problems. Difficult, off-reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

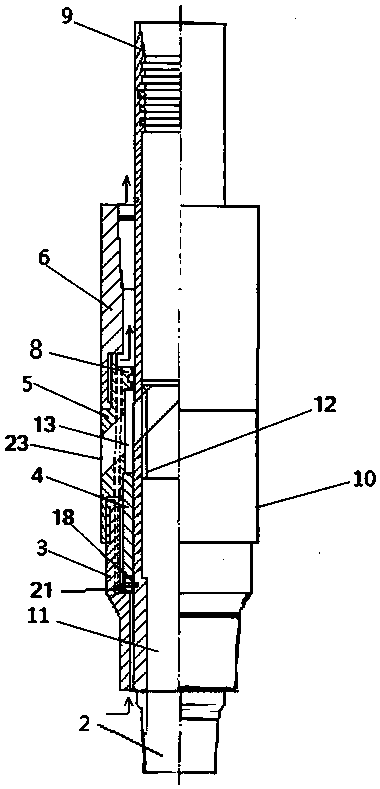

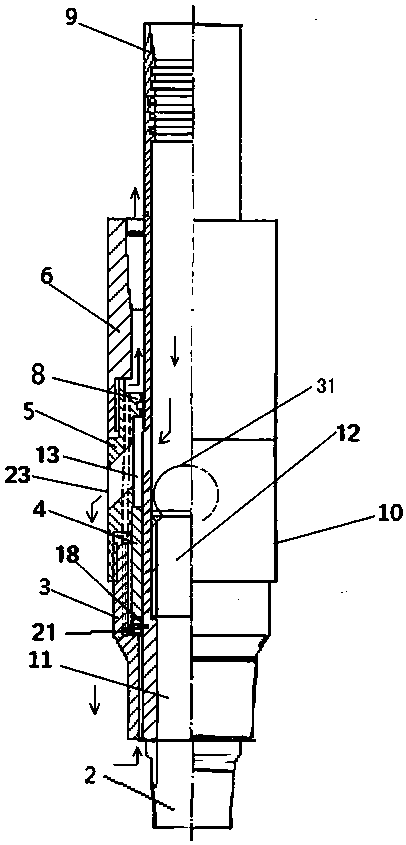

[0026] Embodiment 1, with reference to attached figure 1, an integral layered filling device mentioned in the present invention, its technical solution is: mainly composed of two groups of filling tools 10, sand filter pipe 28, flushing pipe 30 and packer 7, the inner cavity of the filling tool 10 It is connected by flushing pipe 30, and the outer wall is connected by sand filter pipe 28. The upper part of each group of filling tools 10 is provided with a packer 7, and the bottom of the bottom group of filling tools 10 is provided with a blind plug 27. Each group of filling tools 10 is provided with In the corresponding oil layer filling position; wherein, the filling tool 10 includes the lower joint 3 of the filling tool, the sealing sliding sleeve 4, the layered water distribution joint 5, the upper joint 6 of the filling tool, the core tube 11 and the ball seat 12, and the filling The upper joint 6 of the tool and the lower joint 3 of the filling tool are connected with a l...

Embodiment 2

[0040] Embodiment 2, with reference to attached Figure 7 , The difference between the present invention and embodiment 1 is that three sets of filling tools are lowered into the oil well, and the three sets of oil layers are filled in different layers. In specific operation, step three can be repeated to connect and lower the downhole three-component layered filling tool to realize the layered ground filling and ring filling of the three oil layers.

Embodiment 3

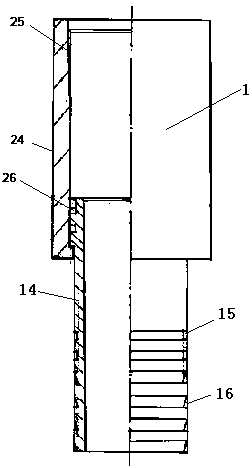

[0041] Embodiment 3, the difference between the present invention and Embodiments 1 and 2 is: the outer wall of the lower part of the inner tube 14 of the present invention is provided with a plurality of snap rings 17, through the snap rings of the inner tube 14 and the next group of filling tools 10 The catcher 9 on the top of the discarding core tube 11 cooperates; the catcher 9 is provided with a plurality of groups of horse teeth buttons corresponding to the snap ring, and the snap ring adopts a circular truncated structure.

[0042] The structure of the present invention can also complete the effective connection and fixation of the hands-free core tube (11) and each group of filling tools (10), and can also play the role of Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com