Oil seal pressing-in mechanism with guide function

An oil seal and function technology, applied in the field of oil seal press-in mechanism, can solve the problems of oil seal tilt, poor sealing effect, scrapped oil seal, etc., and achieve the effect of stable installation process and good sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of the present invention will be described in further non-limiting detail below in combination with preferred embodiments and accompanying drawings.

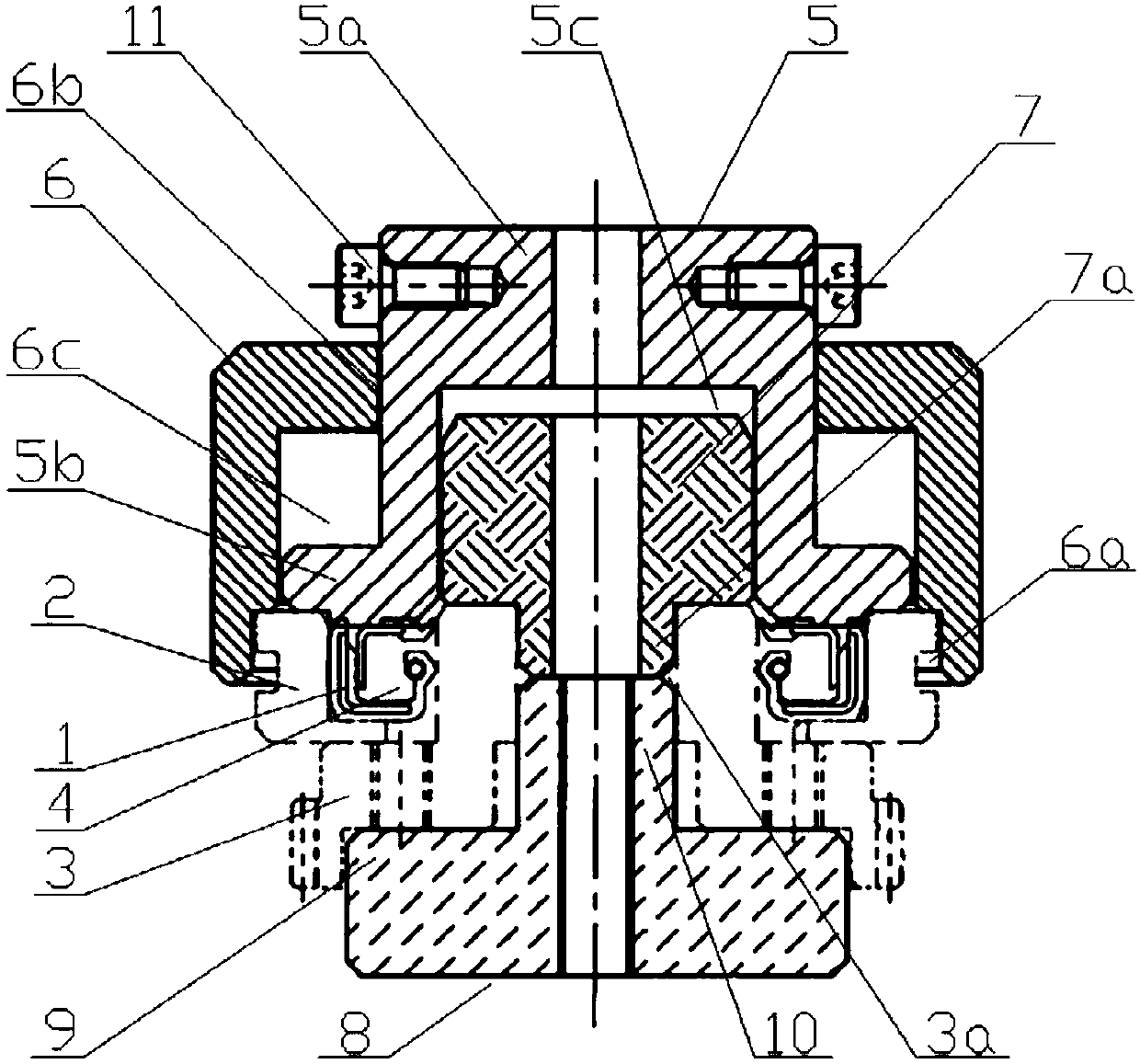

[0014] Such as figure 1 As shown, the oil seal press-in mechanism with guide function corresponding to a preferred embodiment of the present invention is used to install the oil seal 1 into the installation hole 4 formed by the oil seal sleeve 2 and the gear 3, which includes a press-in head 5 and The inner guide block 7 and the outer guide block 6 . The press-in head 5 is used to press the oil seal 1 into the installation hole 4, and it is movably connected with the inner guide block 7, which includes a guide cylinder 5a and an extrusion part 5b coaxially arranged with the guide cylinder 5a. The pressure portion 5b is in contact with the end surface of the oil seal 1 for squeezing the oil seal 1 . The press-in head 5 is also provided with an inner guide hole 5c matched with the inner guide block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com