Vibrating screen for buffering ore impact force

A technology of impact force and vibrating screen, which is applied in the field of mining machinery, can solve the problems of reducing the service life of the vibrator, strong vibration of the vibrating screen, and damage to the motor, and achieve the effects of reducing the impact force, increasing the blanking time, and weakening the impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

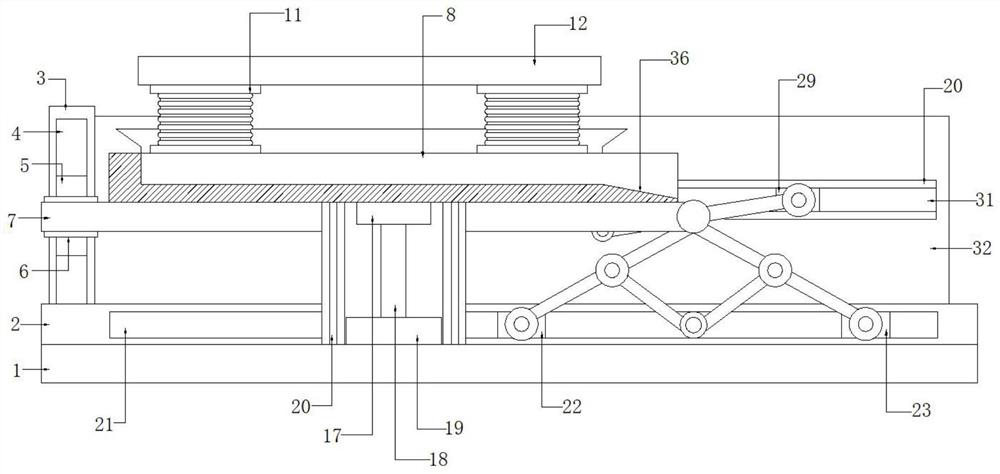

[0030] Such as figure 1 and Figure 3-5 displayed in:

[0031]The present invention provides a vibrating screen suitable for cushioning the impact force of ore. Its structure includes a support base 1, a support column 2 is provided on the top side of the support base 1, and a vertical plate 3 is provided at the top end of the support column 2. , the side of the riser 3 is provided with a chute 4, the chute 4 is provided with a slider 5 matching with the chute 4, and the slider 5 is far away from the chute One side of groove one 4 is provided with fixed plate one 6, described fixed plate one 6 and one side away from described slide block one 5 are provided with horizontal plate 7, and the top of described horizontal plate 7 is provided with collecting bin 8, so The collecting chamber 8 is provided with a collecting chamber 9, and the collecting chamber 9 is provided with a discharge port 10 at one end away from the vertical plate 3, and the four ends around the top of the co...

Embodiment 2

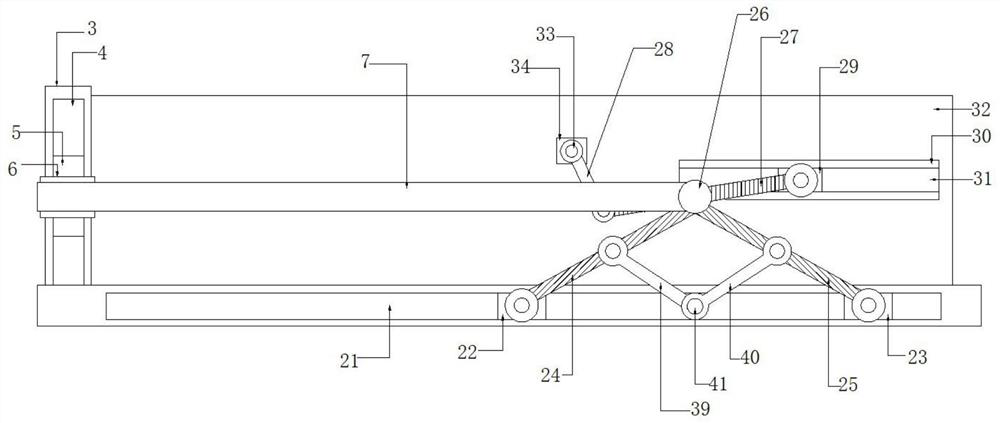

[0034] Such as figure 1 , 6 displayed in:

[0035] The present invention provides a vibrating screen suitable for cushioning the impact force of ore. Its structure includes a support base 1, a support column 2 is provided on the top side of the support base 1, and a vertical plate 3 is provided at the top end of the support column 2. , the side of the riser 3 is provided with a chute 4, the chute 4 is provided with a slider 5 matching with the chute 4, and the slider 5 is far away from the chute One side of groove one 4 is provided with fixed plate one 6, described fixed plate one 6 and one side away from described slide block one 5 are provided with horizontal plate 7, and the top of described horizontal plate 7 is provided with collecting bin 8, so The collecting chamber 8 is provided with a collecting chamber 9, and the collecting chamber 9 is provided with a discharge port 10 at one end away from the vertical plate 3, and the four ends around the top of the collecting ch...

Embodiment 3

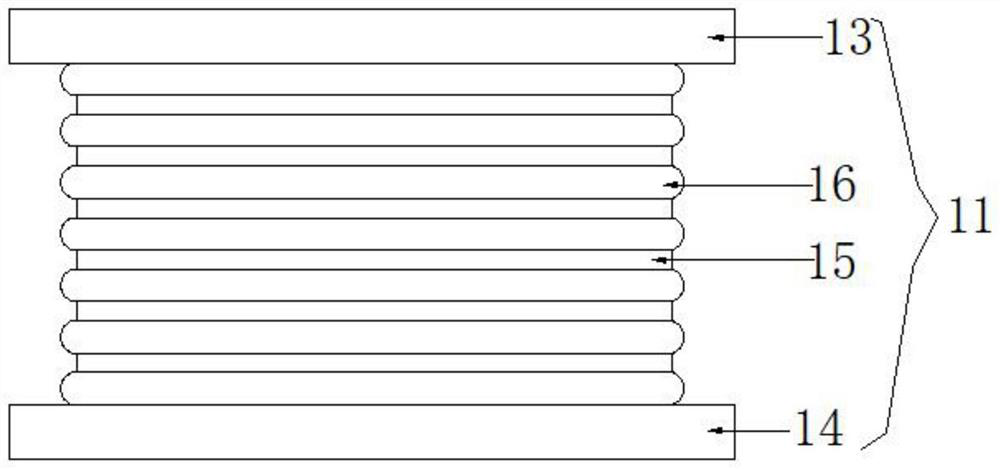

[0038] Such as Figure 1-2 displayed in:

[0039] The present invention provides a vibrating screen suitable for cushioning the impact force of ore. Its structure includes a support base 1, a support column 2 is provided on the top side of the support base 1, and a vertical plate 3 is provided at the top end of the support column 2. , the side of the riser 3 is provided with a chute 4, the chute 4 is provided with a slider 5 matching with the chute 4, and the slider 5 is far away from the chute One side of groove one 4 is provided with fixed plate one 6, described fixed plate one 6 and one side away from described slide block one 5 are provided with horizontal plate 7, and the top of described horizontal plate 7 is provided with collecting bin 8, so The collecting chamber 8 is provided with a collecting chamber 9, and the collecting chamber 9 is provided with a discharge port 10 at one end away from the vertical plate 3, and the four ends around the top of the collecting cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com